Novel roasting machine

A frying dryer, a new type of technology, applied in pre-extraction tea processing, food processing, food science and other directions, which can solve the problems of easy leakage of materials, high manufacturing costs, and inability to quickly enter and exit materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

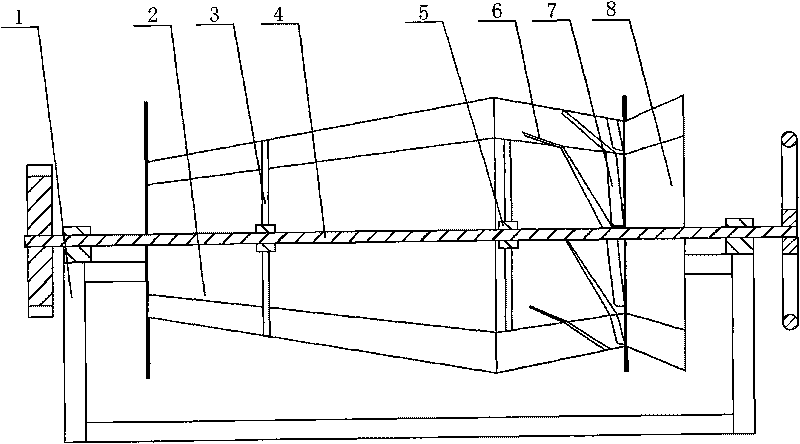

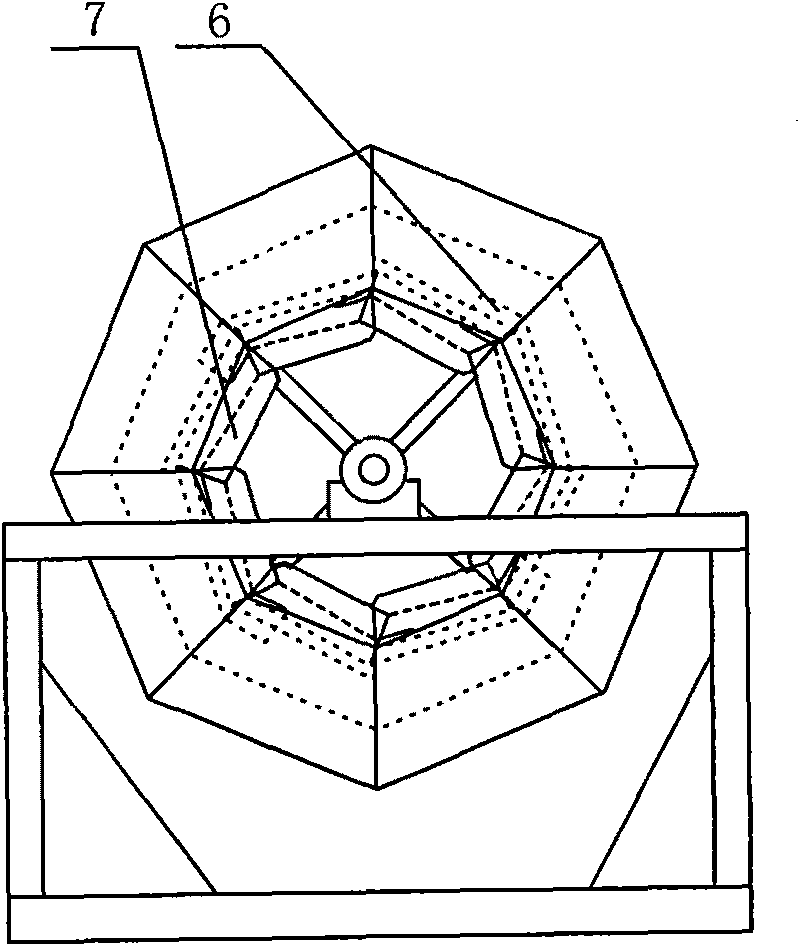

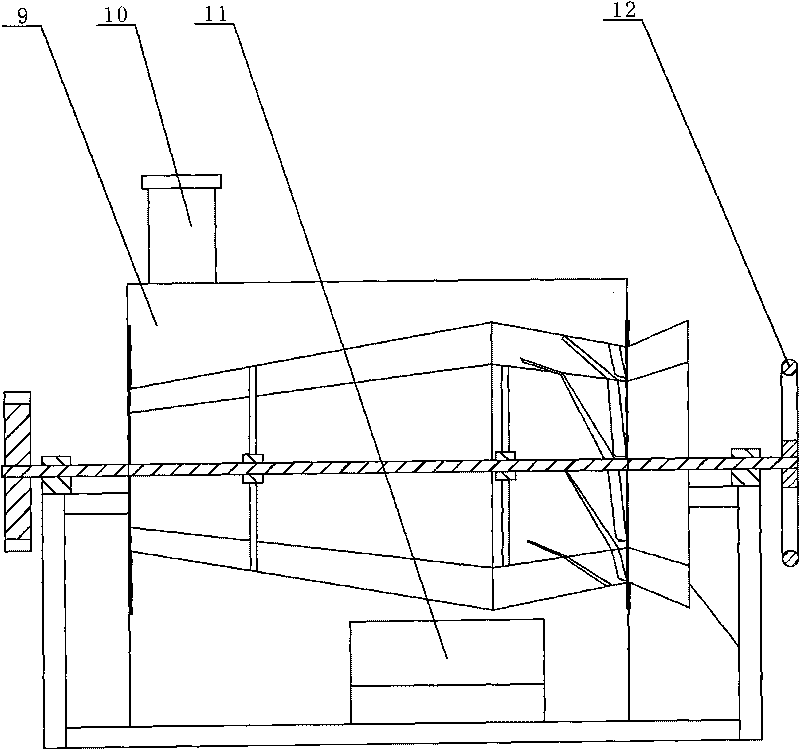

[0020] Such as figure 1 and figure 2 Among them, a new type of frying machine, including a frame 1, a transmission mechanism is provided at one end of the rotating shaft 4, the rotating shaft 4 is installed on the frame 1 through a bearing, and the rotating shaft 4 is connected with the support rod 3 and the inner wall of the heating cylinder 2 through a connecting piece 5 A plurality of guide vanes 7 are provided at the connection between the heating cylinder 2 and the inlet and outlet 8, and a stirring vane 6 is provided at one end of the guide vanes 7.

[0021] The included angle between the guide vane 7 and the shaft 4 projected on the horizontal plane gradually decreases from the entrance of the heating cylinder 2 inwards, and the height of the guide vane 7 gradually decreases from the entrance of the heating cylinder 2 inwards. The included angle here is when the guide vane 7 is at the bottom, the included angle between the tangent of each point on the projection of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com