Sampling device for analyzer and sampling analysis and control method

A sampling device and sampling analysis technology, applied in sampling devices, testing water, material inspection products, etc., can solve the problems of reducing energy consumption, high price, unfavorable cost saving, etc., and achieve the effect of saving investment cost and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

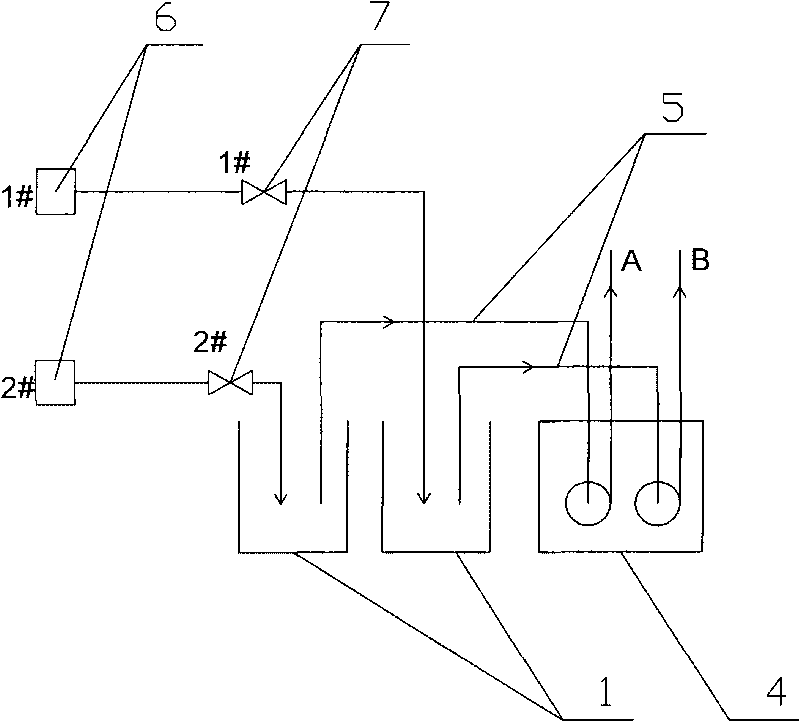

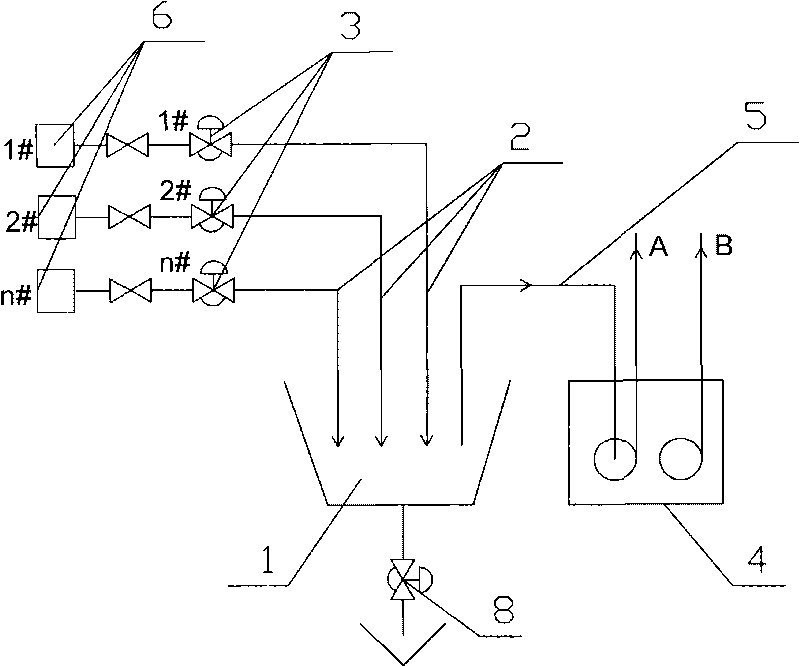

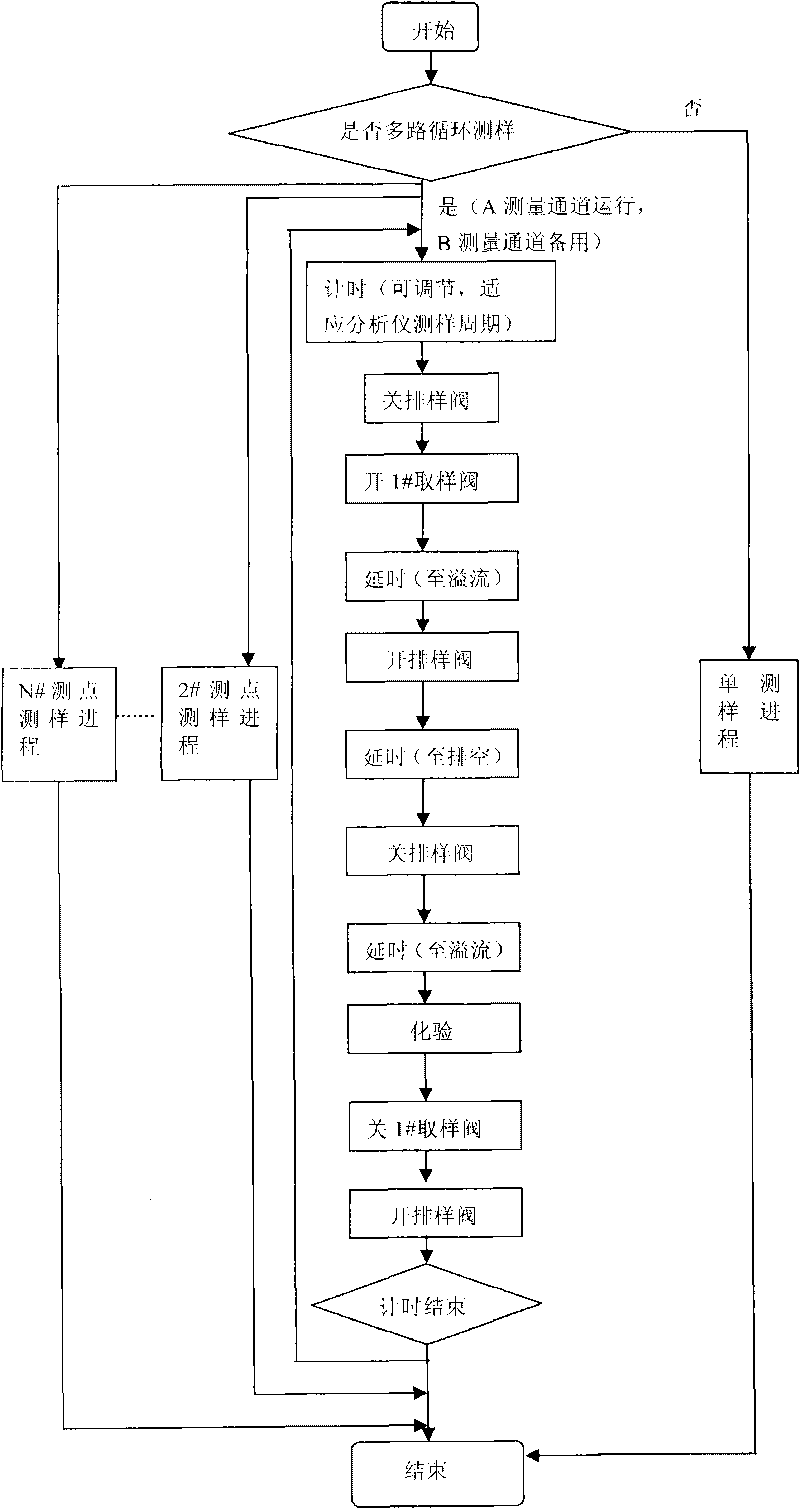

[0026] Such as figure 2 As shown, this embodiment provides a sampling device for a water quality analyzer, including a sampling tank 1 and a sampling pipeline, wherein the sampling tank 1 is in the shape of an inverted cone with a wide top and a narrow bottom, with a taper of 10.5° and a bottom-to-height ratio of 0.275 . Described sampling pipeline comprises the branch pipeline 2 that multiple roads independently access this sampling tank 1, and each branch pipeline 2 in described sampling pipeline is provided with the sampling electromagnetic valve 3 that is connected with controller respectively; Described sampling tank bottom is provided with Connect to the discharge valve 8 of the discharge pipe. The outlets of the sampling pipelines are arranged at a distance ratio of 0.1 to 0.5 between the top and the bottom. The angle between the liquid flow direction and the radial direction is less than 90°, and the liquid flow direction is horizontal and slightly downward. The to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com