Method for preparing nanoscale pesticide preparation by means of silicon dioxide aerogel

A silicon dioxide and pesticide preparation technology, applied in the field of pesticides, can solve the problems of difficulty in achieving high drug loading, large specific surface area and stable quality, low content of main drugs, and inability to achieve, saving equipment investment and maintenance costs, The effect of long stabilization time, increased production cost and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

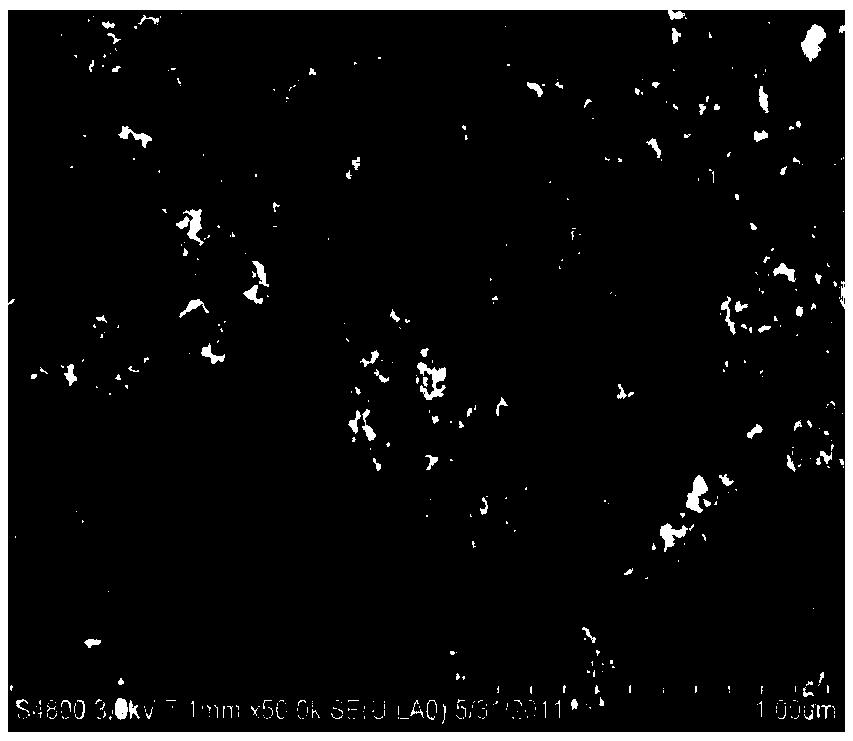

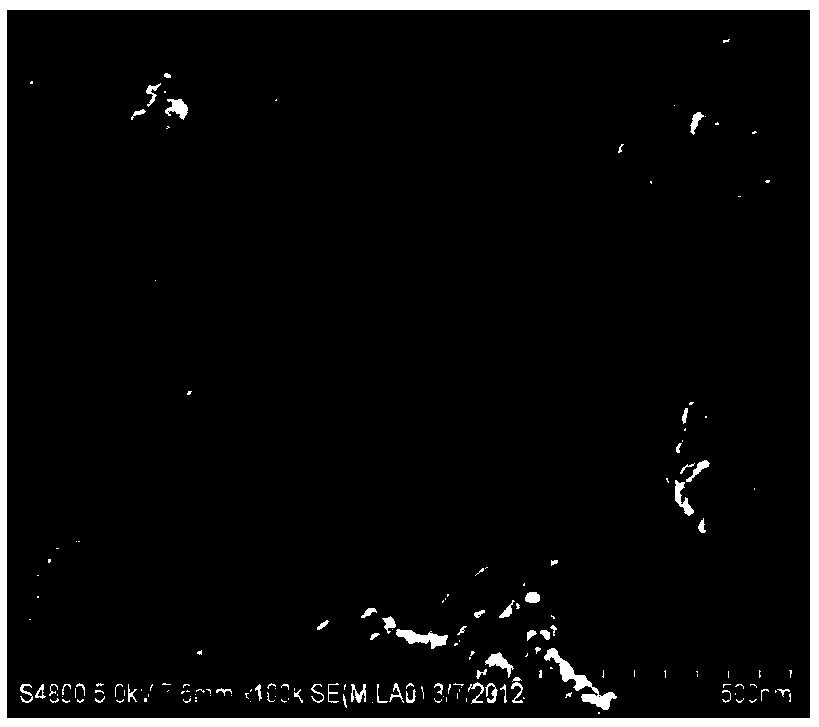

Image

Examples

Embodiment 1

[0037] Preparation technology of nano-scale abamectin drying

[0038] 1 Drug dissolution and adsorption drug loading

[0039] 1.1 Precisely weigh 250 grams of Abamectin original drug

[0040] 1.2 Precisely weighed silica aerogel 250g

[0041] 1.3 Measure 500 ml of solvent ethyl acetate (analytical grade), dissolve it into a light yellow clear liquid, add 1500 ml of absolute ethanol (analytical grade) to dilute.

[0042] 1.4 Add 250 g of aerogel until the drug solution is completely adsorbed.

[0043] 2 Nanodispersion or Microsphere Preparation

[0044] 2.1 The obtained drug carrier was placed in a beaker, and 2000 ml of absolute ethanol was added.

[0045] 2.2 Emulsification by high-speed emulsifying machine, parameters: rotating speed 10000 rpm, time 5 minutes.

[0046] 2.3 Use a drying oven to dry the emulsion, parameters: temperature 100°C, time 12 hours.

[0047] 2.4 Pulverize the semi-finished product through a 200-mesh sieve to obtain nano-avermectin powder.

Embodiment 2

[0049] Nanometer methylamino abamectin benzoate (carboxylate) drying preparation technology

[0050] 1 Drug dissolution and adsorption drug loading

[0051] 1.1 Precisely weighing 250 grams of the original drug of methylamino abamectin benzoate

[0052] 1.2 Precisely weighed silica aerogel 250g

[0053] 1.3 Weigh 7g of D902 anti-decomposition agent (Shenzhen Langtai Biotechnology Co., Ltd.), measure 2000 ml of solvent absolute ethanol (analytical grade), and prepare an alcohol solution with a concentration of 0.35%.

[0054] 1.4 Add the above alcohol solution to dissolve the original drug of Avermectin Benzoate to a brown clear liquid.

[0055] 1.4 Add 250 g of aerogel until the drug solution is completely adsorbed.

[0056] 2 Nanodispersion or Microsphere Preparation

[0057] 2.1 The obtained drug carrier is placed in a beaker, 2000 ml of purified water is added, and the mixture is stirred.

[0058] 2.2 Emulsifying by high-speed emulsifying machine, parameters: rotating ...

Embodiment 3

[0062] Preparation technology of nanometer ivermectin drying

[0063] 1 Drug dissolution and adsorption drug loading

[0064] 1.1 Precisely weigh 250 grams of ivermectin original drug

[0065] 1.2 Precisely weighed silica aerogel 250g

[0066] 1.3 Measure 2000 ml of solvent anhydrous ethanol (analytical grade) and dissolve it into a light yellow clear liquid.

[0067] 1.4 Add 250 g of aerogel until the drug solution is completely adsorbed.

[0068] 2 Nanodispersion or Microsphere Preparation

[0069] 2.1 The obtained drug carrier is placed in a beaker, 2000 ml of purified water is added, and the mixture is stirred.

[0070] 2.2 Emulsifying by high-speed emulsifying machine, parameters: rotating speed 28000 rpm, time 5 minutes.

[0071] 2.3 Use a drying oven to dry the emulsion, parameters: temperature 120°C, time 12 hours.

[0072] 2.4 Pulverize the semi-finished product through a 200-mesh sieve to obtain nanometer ivermectin powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com