Method for changing refractory brick at tapping hole of direct current electric arc furnace

A technology of DC electric arc furnace and replacement method, which is applied in the direction of lining repair, etc. It can solve the problems that the closed DC electric arc furnace cannot be used and the melt can not be evacuated, and achieve the effect of short replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

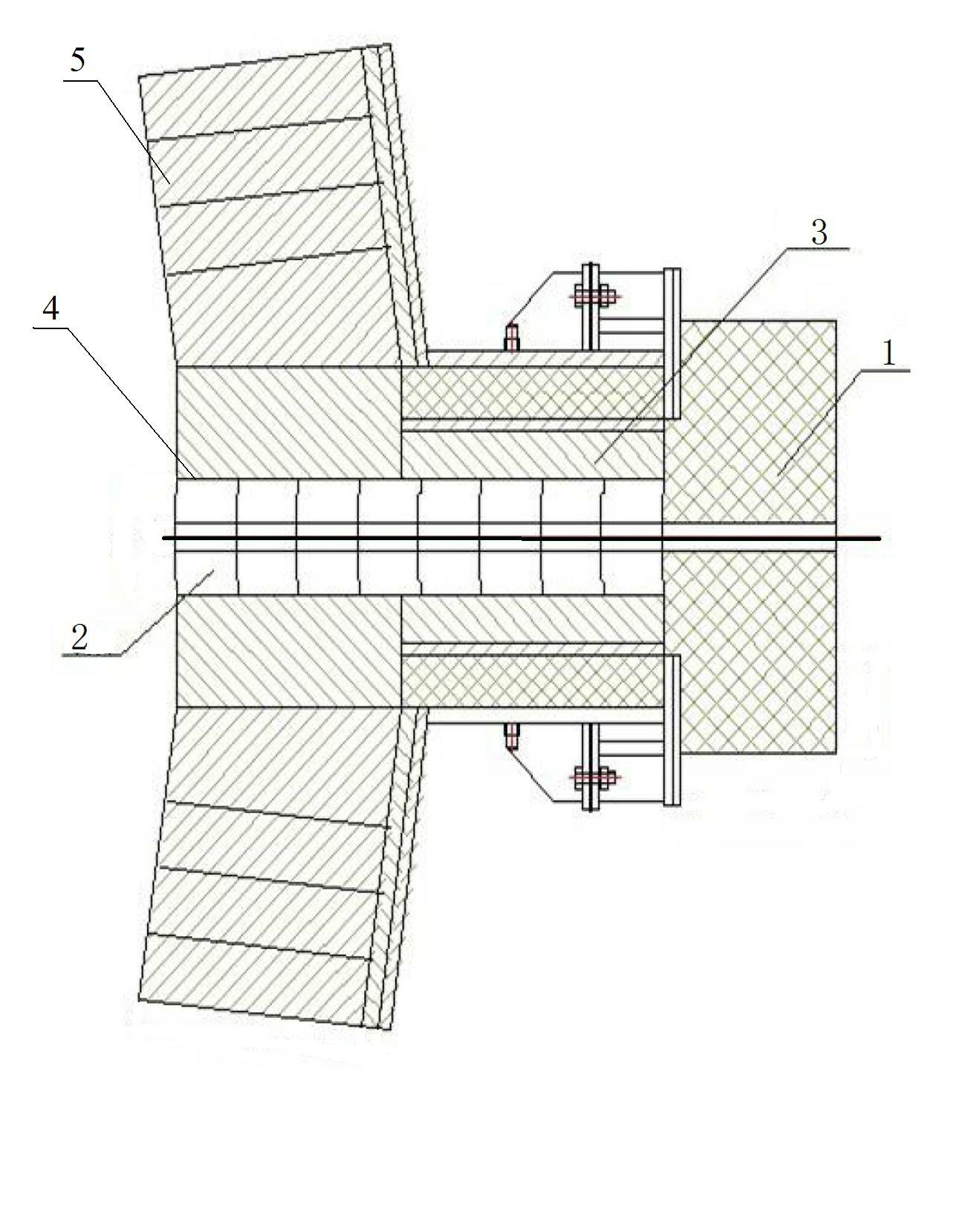

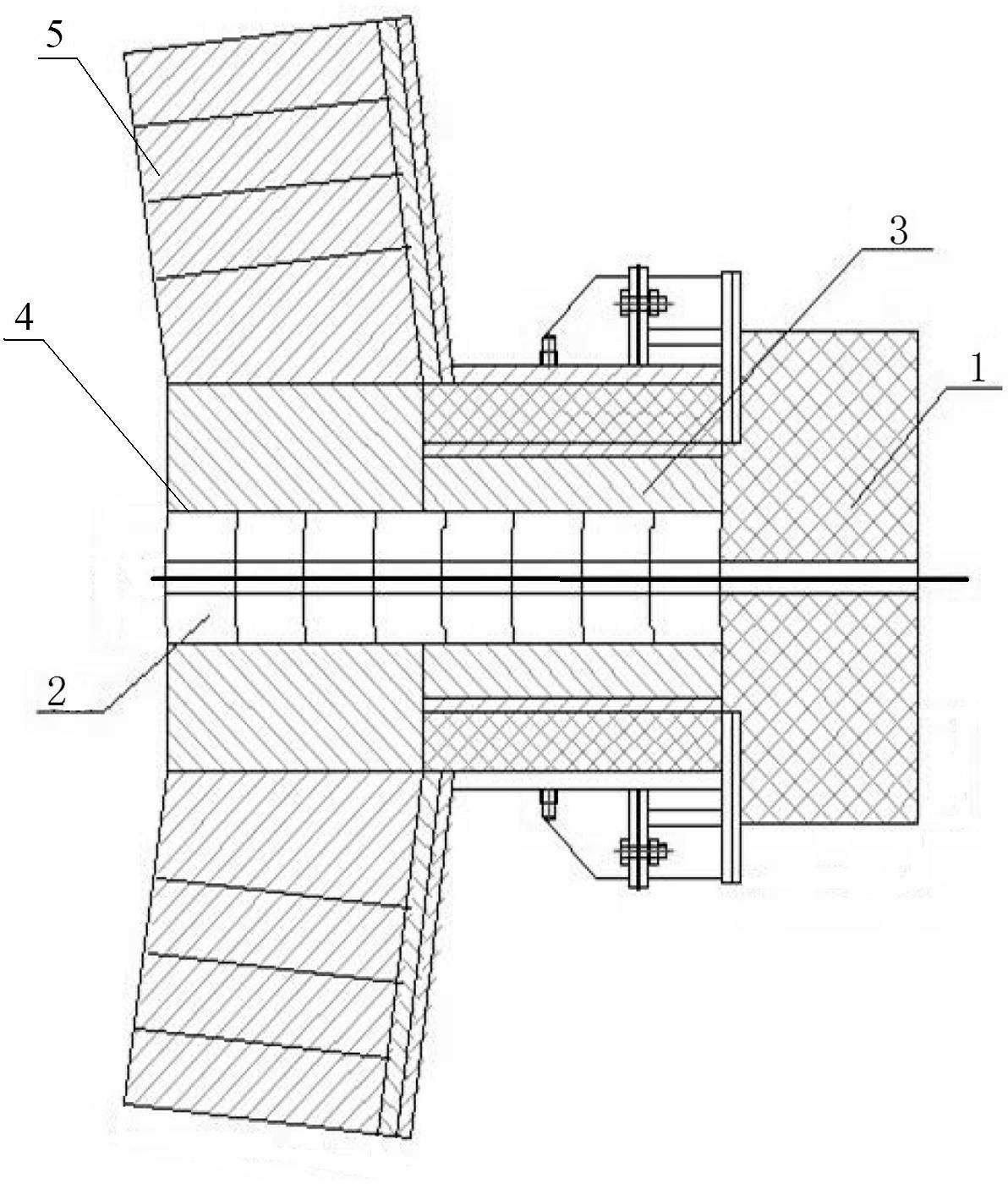

[0012] A method for replacing refractory bricks at the iron gate of a DC electric arc furnace, the steps of the invention are:

[0013] (1) Stop feeding the furnace for heat preservation; (2) Drain the molten iron above the tap hole; (3) Clean up the outermost castable ① of the tap hole; (4) Shut down the furnace; (5) Remove the damaged refractory brick ②; (6) Build new refractory materials; (7) Restore the outermost castable ① of the iron gate; (8) Start the furnace and resume production.

[0014] Wherein: step (2) discharges the molten iron above the taphole, without emptying the melt in the furnace, only needs to empty the molten iron above the taphole.

[0015] Step (4) shut down the furnace, because the replacement time is short, there is no need to shut down the furnace for a long time.

[0016] Step (8) Start the furnace, because the replacement time is short and the temperature in the furnace will not be too low, so there is no need to carry out long-term temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com