Preparation method for producing cupronickel B30 raw material from copper-nickel slag

A technology of copper-nickel slag and B30, applied in the field of smelting, can solve the problems of incomplete homogenization of elements such as copper-nickel-iron and high cost, and achieve significant environmental protection benefits and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A kind of copper-nickel slag produces the preparation method of cupronickel B30 raw material, and its technological process is:

[0021] a. Crush the copper-nickel slag material to about 50mm, and the water content after drying is less than 10%;

[0022] b. Mix the dried copper-nickel slag material, reducing agent and flux in proportion and then add them to the DC electric arc furnace;

[0023] c. Control the temperature of the DC electric arc furnace at 1380°C-1500°C, the feeding time is 30-60 minutes, the holding time is 30-60 minutes, and the slag and copper-nickel alloy are separated;

[0024] d. Copper-nickel alloy is desulfurized, decarburized, and impurity-removed through AOD furnace and other equipment to prepare qualified white copper B30 raw materials.

[0025] Further, the amount of the reducing agent added in step b is 5-7.5% of the copper-nickel slag on a dry basis.

[0026] Further, the amount of flux added in step b is 13-15% of the dry copper-nickel sl...

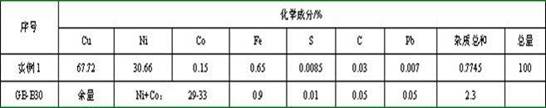

Embodiment 1

[0031] First, after the copper-nickel slag is naturally dried, its water content is less than 10%, and a certain amount of dry base copper-nickel slag is weighed, and the reducing agent is weighed according to 5% of the copper-nickel slag amount, and the auxiliary agent is weighed according to 13% of the copper-nickel slag amount. Flux: All materials are weighed and mixed in a small amount and added to the hot DC electric arc furnace in batches. The melting temperature of the DC electric arc furnace is controlled at 1380°C, the feeding time is 30 minutes, and the holding time is 30 minutes. After the holding is completed, the slag and copper-nickel alloy are separated. The copper-nickel alloy is transported to the AOD furnace; the desulfurizer is weighed according to 1% of the alloy amount; the oxygen blowing decarburization, desulfurization by adding the desulfurizer in batches, etc. are refined, after the impurity removal is completed, the casting is carried out, and the chemi...

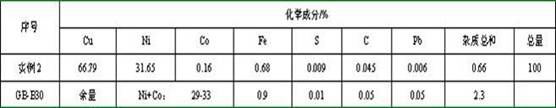

Embodiment 2

[0035] First, after the copper-nickel slag is naturally dried, its water content is less than 10%, and a certain amount of dry base copper-nickel slag is weighed, and the reducing agent is weighed according to 6% of the copper-nickel slag amount, and the auxiliary agent is weighed according to 14% of the copper-nickel slag amount. Flux: All materials are weighed and mixed in a small amount and added to the hot DC electric arc furnace in batches. The melting temperature of the DC electric arc furnace is controlled at 1450°C, the feeding time is 50 minutes, and the holding time is 50 minutes. After the holding, the slag and copper-nickel alloy are separated. The copper-nickel alloy is transported to the AOD furnace; the desulfurization agent is weighed according to 1% of the alloy amount; oxygen blowing decarburization, adding desulfurization agent in batches for desulfurization and other refining, casting after impurity removal, cooling sampling chemical composition analysis, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com