Direct-current arc furnace for preparing magnesium oxide single-crystal

A DC electric arc furnace and magnesia technology are applied in the field of electrofusion devices for preparing magnesium oxide single crystals, and DC electric arc furnaces for preparing magnesium oxide single crystals, and can solve the impact of voltage fluctuations in power grids, large electrode consumption, low crystal yield, etc. problems, to achieve the effect of reducing voltage fluctuation and impact on the power grid, reducing electrode consumption, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

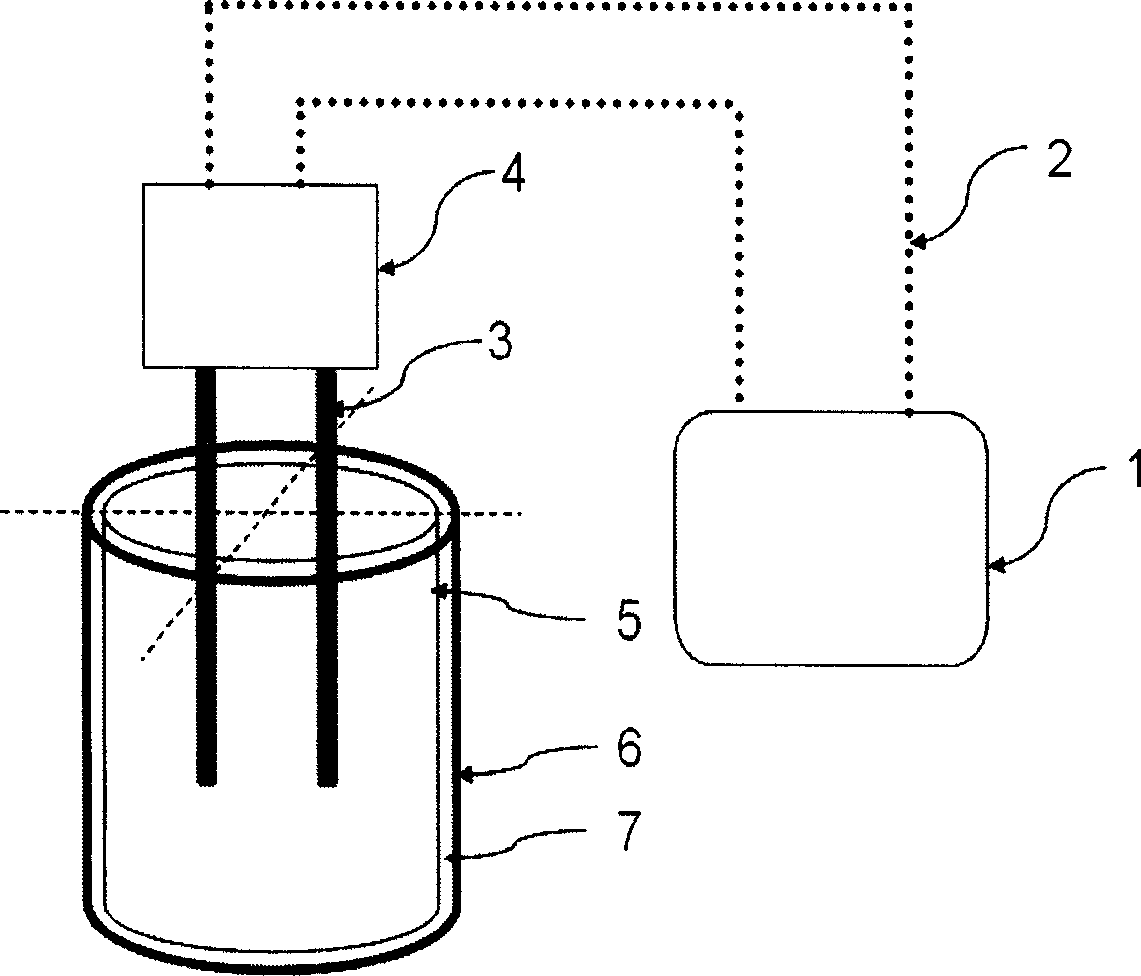

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

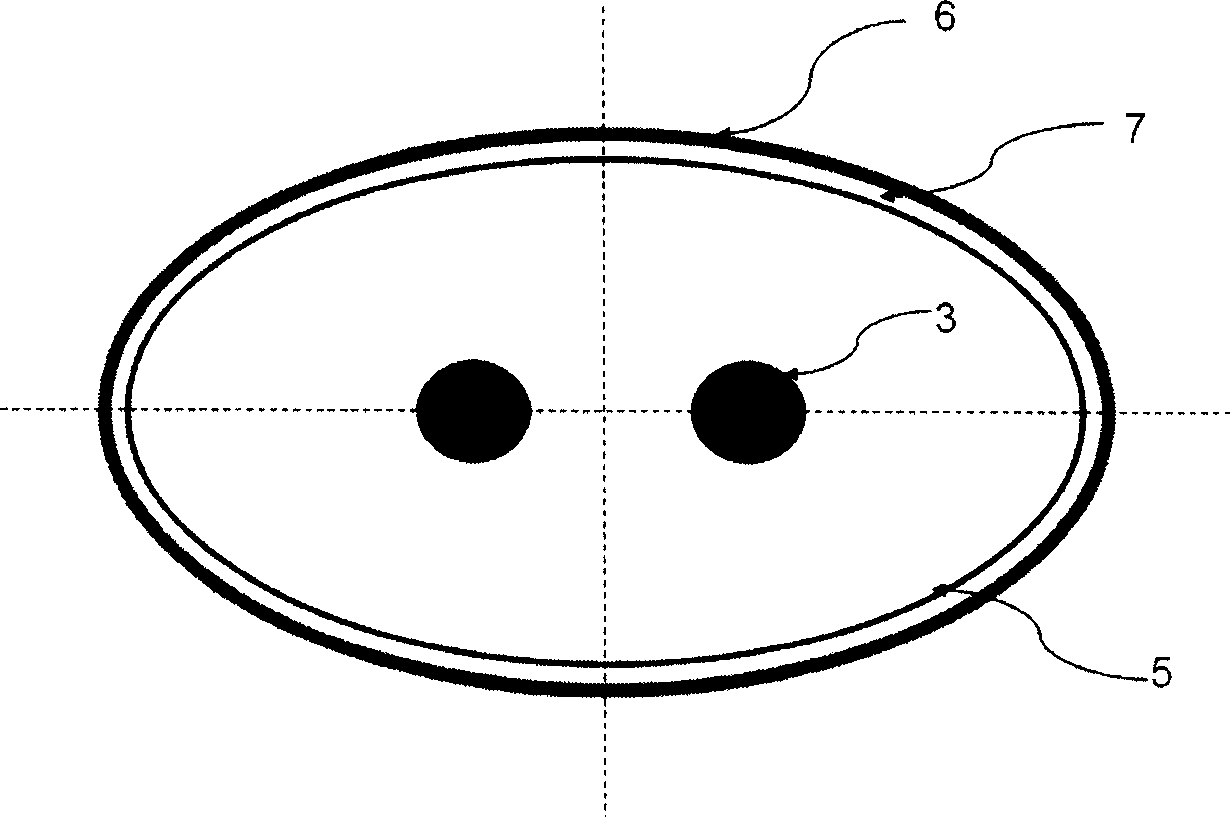

[0012] The furnace shell has an elliptical cylindrical structure. The inner wall 5 of the furnace shell is made of stainless steel plate, and the outer wall 6 of the furnace shell is made of glass fiber reinforced plastic. There is an air gap 7 between the two layers of furnace shells. At the two focal points of the furnace shell, the power grid supplies power to the DC smelting power supply 1, and the electric energy is transmitted to the graphite electrode 3 through the water-cooled cable 2, and the electrode lifting mechanism 4 can complete the lifting action of the electrode in the furnace.

[0013] In the case of the same raw material and power consumption, the crystal output and quality of the electric arc furnace are greatly improved compared with ordinary electric arc furnaces. In addition, the electric arc furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com