High-performance direct-current power supply implementation method of direct-current electric arc furnace

A DC electric arc furnace, DC power supply technology, applied in high-efficiency power electronic conversion, AC power input conversion to DC power output, electrical components and other directions, can solve the problem of large investment, poor power factor, thyristor rectifier system power factor variation question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

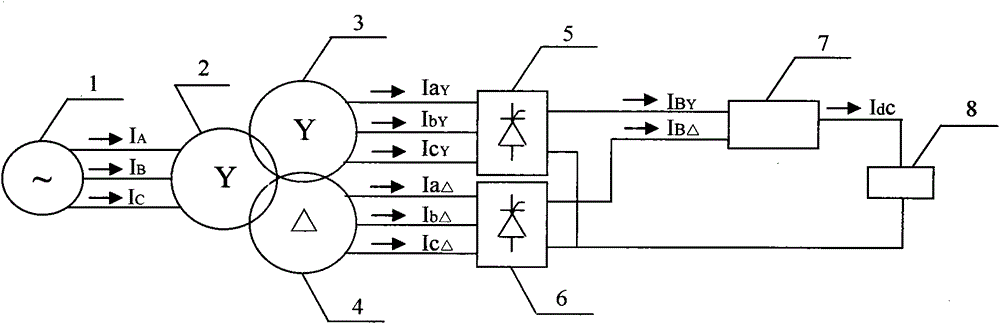

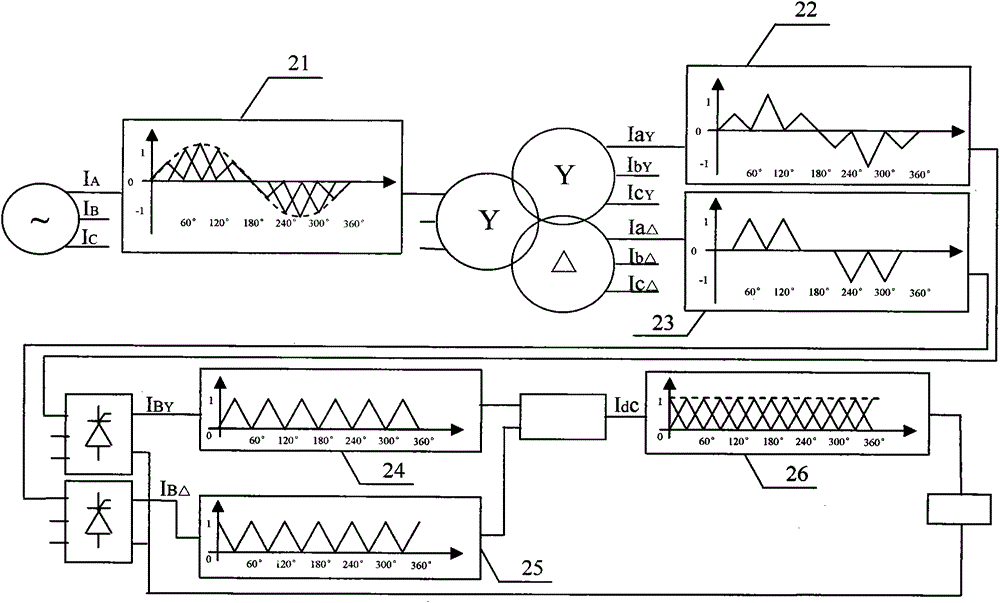

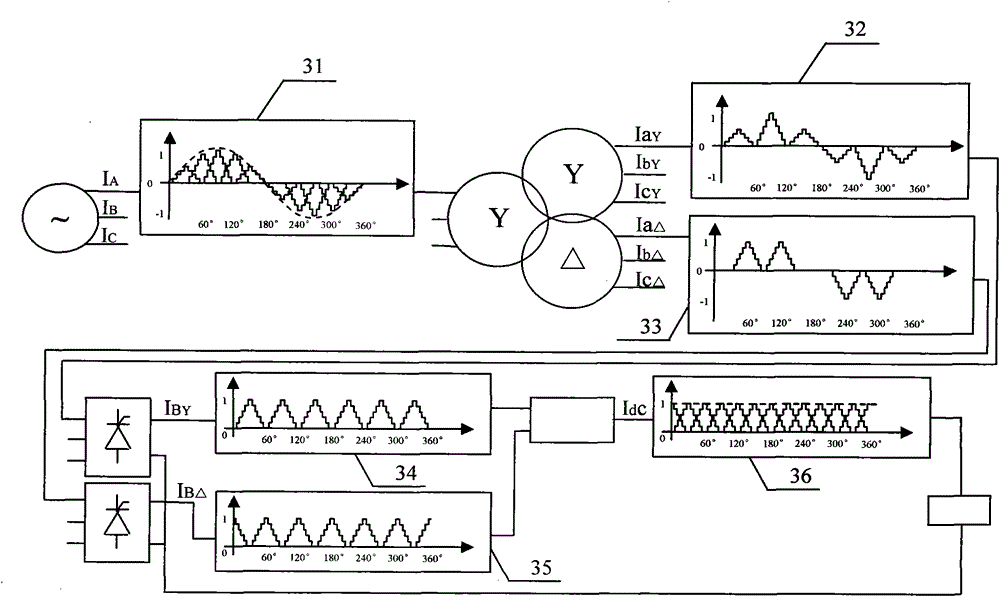

[0024] Whether the DC power supply of the existing DC electric arc furnace adopts a 6-pulse rectification device or a 12-pulse rectification device, it has little effect on the actual smelting effect, and there is not much difference in the reactive power compensation capacity of the two. The difference mainly lies in the power grid The capacity of side filter device configuration is different. Due to the fact that the harmonic content cannot meet the requirements and the power factor is low, the existing DC electric arc furnace power supply and distribution system has to add a power distribution system for reactive power compensation and harmonic filtering, and has to increase the DC power appropriately. The capacity of the arc furnace rectifier transformer has resulted in a large and complicated electrical system and an increase in investment. An effective way to improve this situation is to develop DC power supply devices with low harmonics and high power factor.

[0025]A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com