Direct-current electrical arc furnace

A technology of DC electric arc furnace and furnace body, which is applied in the direction of electric furnace heating, furnace, electric charge control, etc., and can solve problems such as hot damage of electrode core and impact on the service life of furnace materials and refractory materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

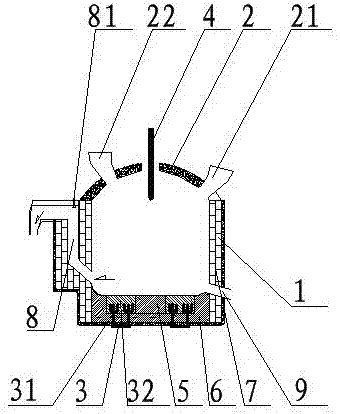

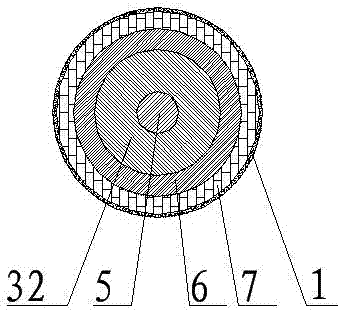

[0011] The DC electric arc furnace of the present invention is mainly composed of a furnace body (1) and a furnace cover (2). The furnace cover (2) is located on the top of the furnace body (1) and is provided with a slag inlet (21) and an auxiliary material inlet (22), there is an electrode insertion hole in the middle part, and a graphite electrode (4) is arranged at the corresponding electrode insertion hole; the furnace body (1) has a cylindrical structure, and its bottom is provided with a ring electrode (3) and a ring electrode (3). ) It consists of two parts: a metal electrode (31) and a refractory electrode (32). The metal electrode (31) is composed of a fork electrode made of multiple copper rods welded on a ring-shaped copper plate. The length of the fork electrode is the thickness of the furnace bottom. 2 / 3, the ring-shaped copper plate is exposed outside the furnace body (1); after positioning the metal electrode (31), first use insulating refractory material (6) to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com