Power supply device and method of DC electric-arc furnace

A technology of DC electric arc furnace and power supply device, applied in the field of metallurgy, which can solve problems such as limited voltage regulation range, repeated oscillation of the system, overshoot of the regulation system, etc., and achieve the effect of meeting the demand of power supply current and stabilizing power energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

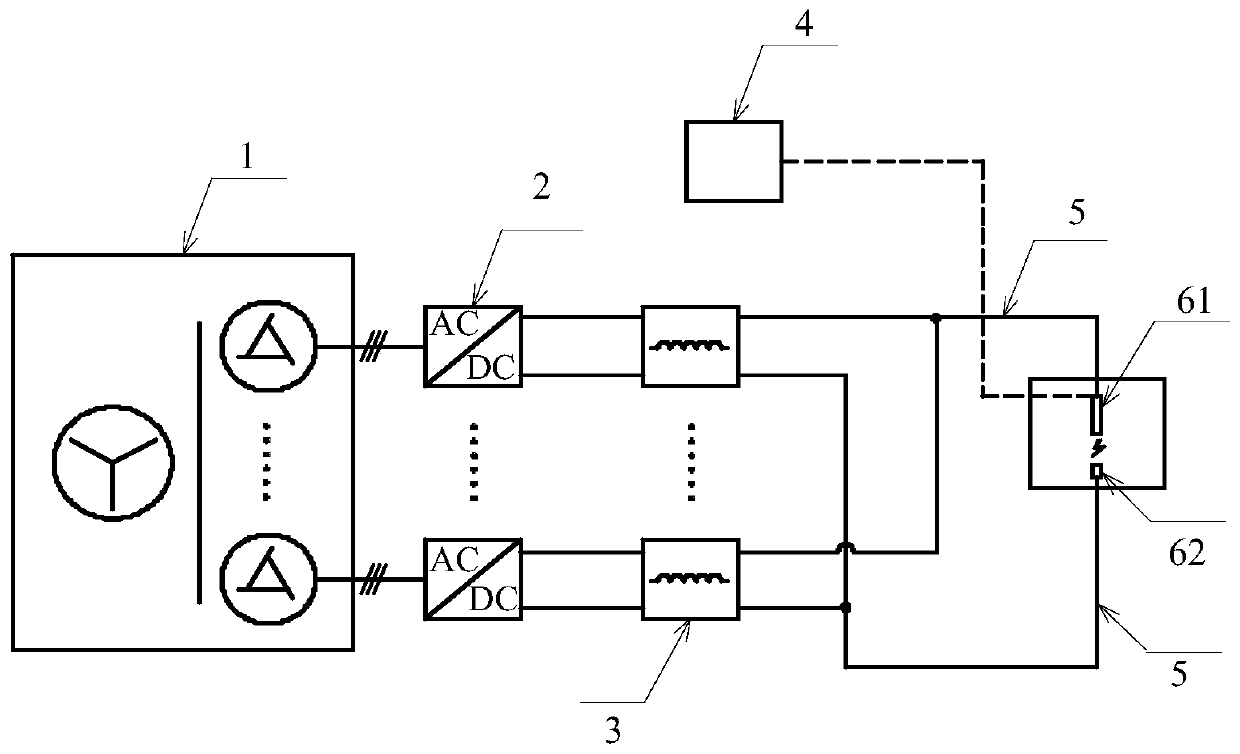

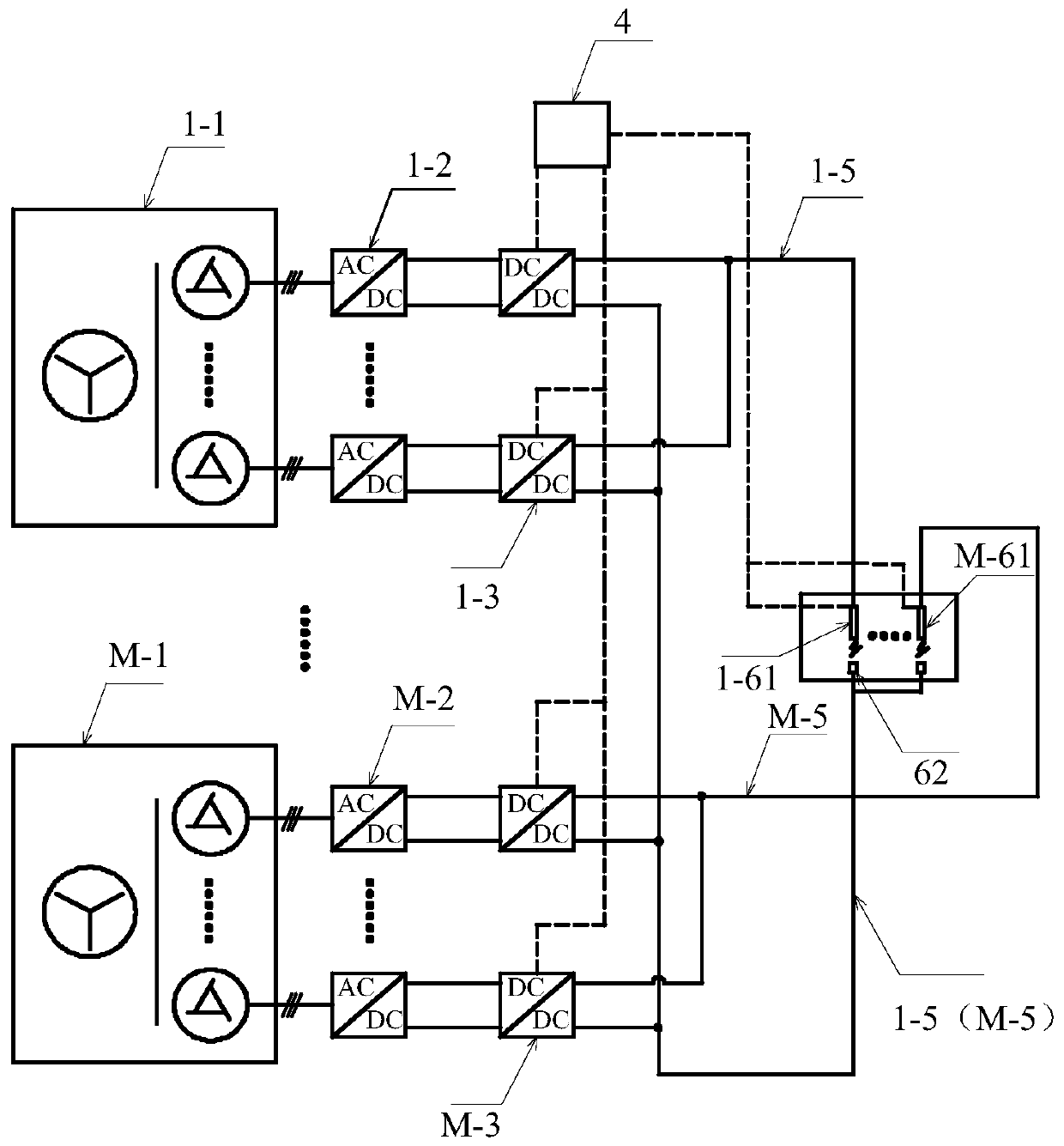

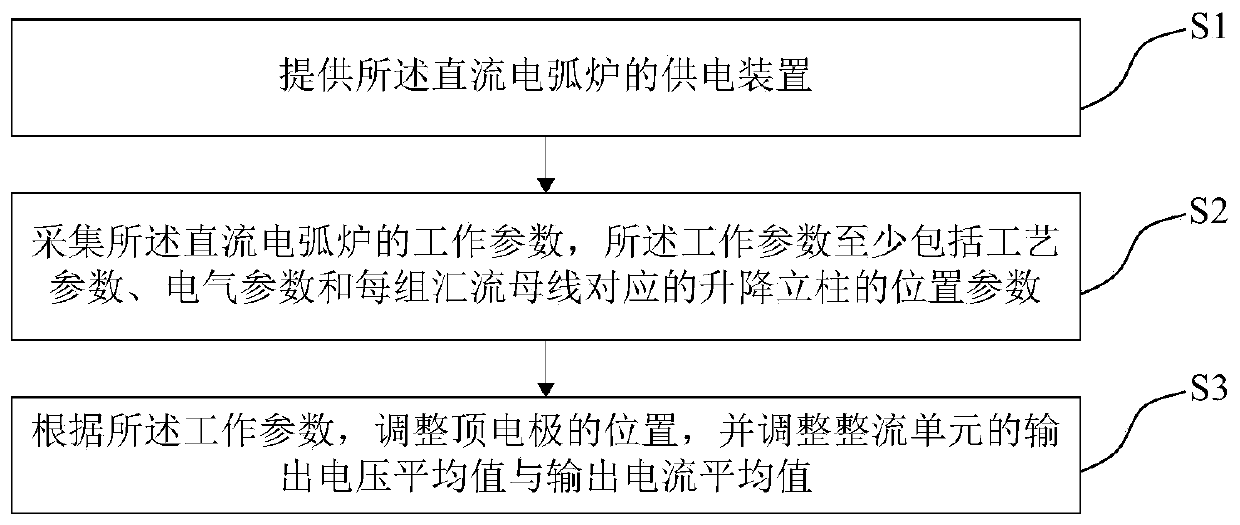

[0064] As mentioned above in the background technology, such as figure 1 As shown, the DC electric arc furnace power supply in the prior art is usually composed of a rectification phase-shifting transformer 1, a rectifier 2 and a series reactor 3, the input terminal of the rectification phase-shifting transformer 1 is connected to the power grid, and the output terminal of the rectification phase-shifting transformer 1 leads to multiple Each of the branches is connected in series with a rectifier 2 and a reactor 3 respectively, and the outputs of the multiple branches are connected in parallel to the short power supply network of the DC electric arc furnace through the confluence bus 5 to form a current output topology. A set of rectifying power supply is obtained, and the alternating current provided by the power grid is stepped down, rectified and combined to supply power for the electrode group of the direct current electric arc furnace. Wherein, the electrode group include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com