Automatic regulating device of DC electric arc furnace electrode and control method thereof

A DC electric arc furnace and automatic adjustment technology, applied in the direction of electric furnace heating, furnace, furnace components, etc., can solve the problems of high power consumption per ton of steel and electrode consumption, large impact on rectifiers, transformers and power grids, and low control accuracy. Control accuracy and response speed, reduce power consumption and electrode consumption, and improve the effect of power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

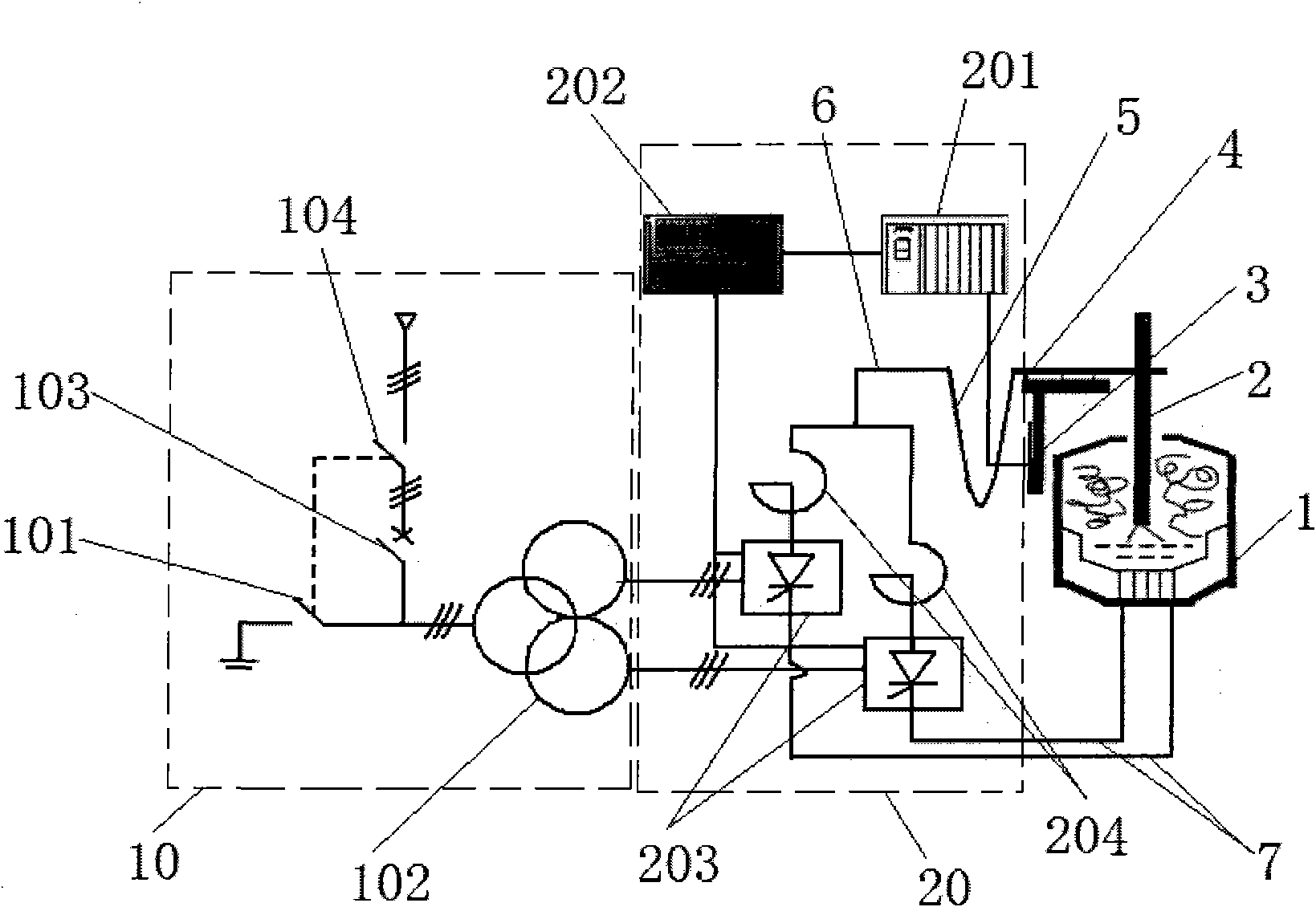

[0018] Such as figure 1 Shown is a schematic diagram of the device structure of the present invention, a DC electric arc furnace arc voltage and arc current automatic adjustment device, including an electric arc furnace 1, a lifting cylinder 3, a conductive copper tube 4, a graphite electrode 2, and an arc voltage and arc current adjustment control system 20 and the main power circuit 10, the electric arc furnace 1 is provided with a lifting cylinder 3 on the outside, and a conductive copper tube 4 is installed on the top of the lifting cylinder 3, and the end of the conductive copper tube 4 is provided with a vertical graphite electrode 2 to the inside of the electric arc furnace 1 , the arc voltage and arc current regulation control system 20 is connected to the conductive copper pipe 4 , the lifting cylinder 3 and the electric arc furnace 1 , and is also connected to the main power circuit 10 .

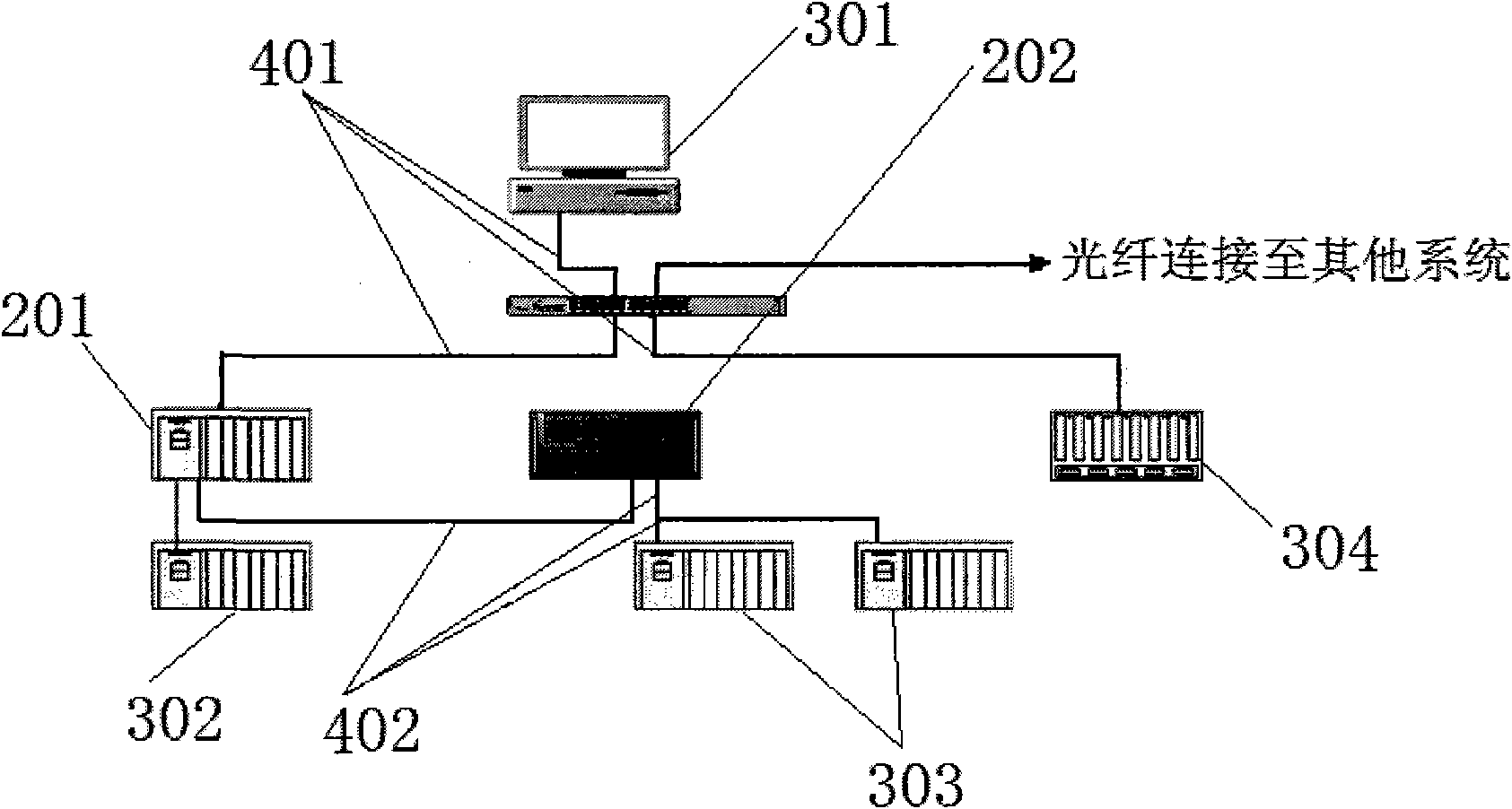

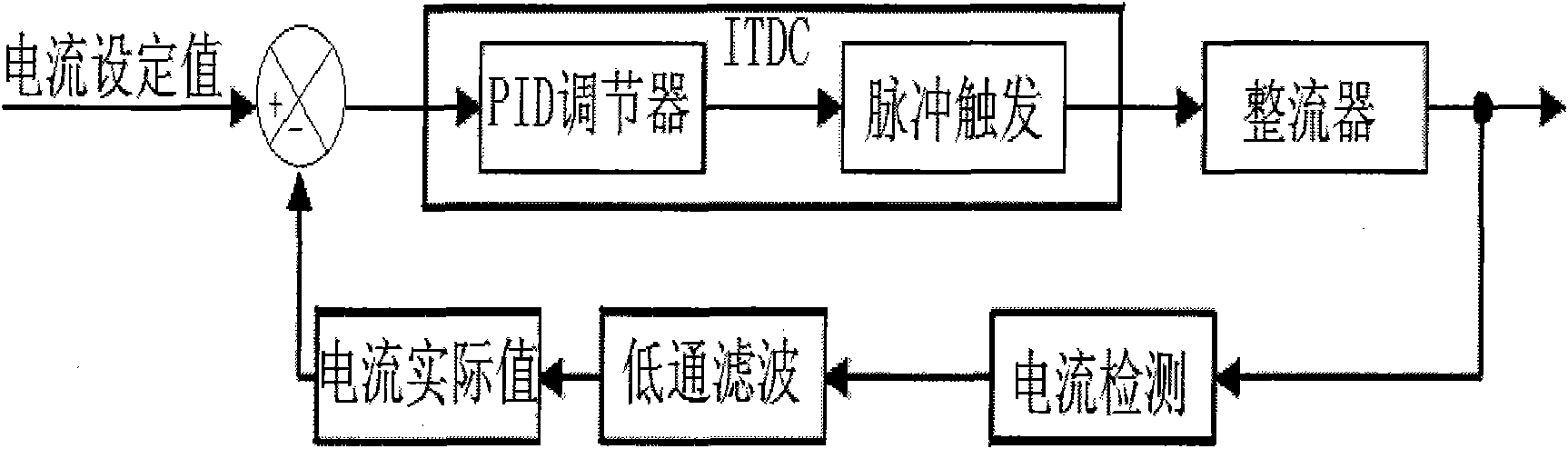

[0019] The arc voltage and arc current adjustment control system 20 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com