Method of preparing titanium and titanium alloy using titanium containing furnace clinker

A technology of titanium slag and titanium alloy, which is applied in the field of preparing titanium metal by using titanium-containing slag, can solve the problems of reducing the hydration strength of cement and the inability to use cement active admixtures, and achieve the effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A method for preparing titanium and titanium alloys by using titanium-containing slag, the composition of the titanium-containing slag used is: CaO is 24.62wt%, SiO 2 27.97wt%, Al 2 O 3 13.40wt%, MgO is 7.68wt%, Fe 2 O 3 3.19wt%, TiO 2 It is 20.59wt% and MnO<1wt%. With 0-40% metal aluminum, 0-50% carbon, 0-40% iron and 0-20% magnesium as reducing agent, the amount of reducing agent added is not zero at the same time, and the mixture is evenly mixed in the plasma furnace It melts and undergoes thermal reduction reaction to obtain titanium and titanium alloy.

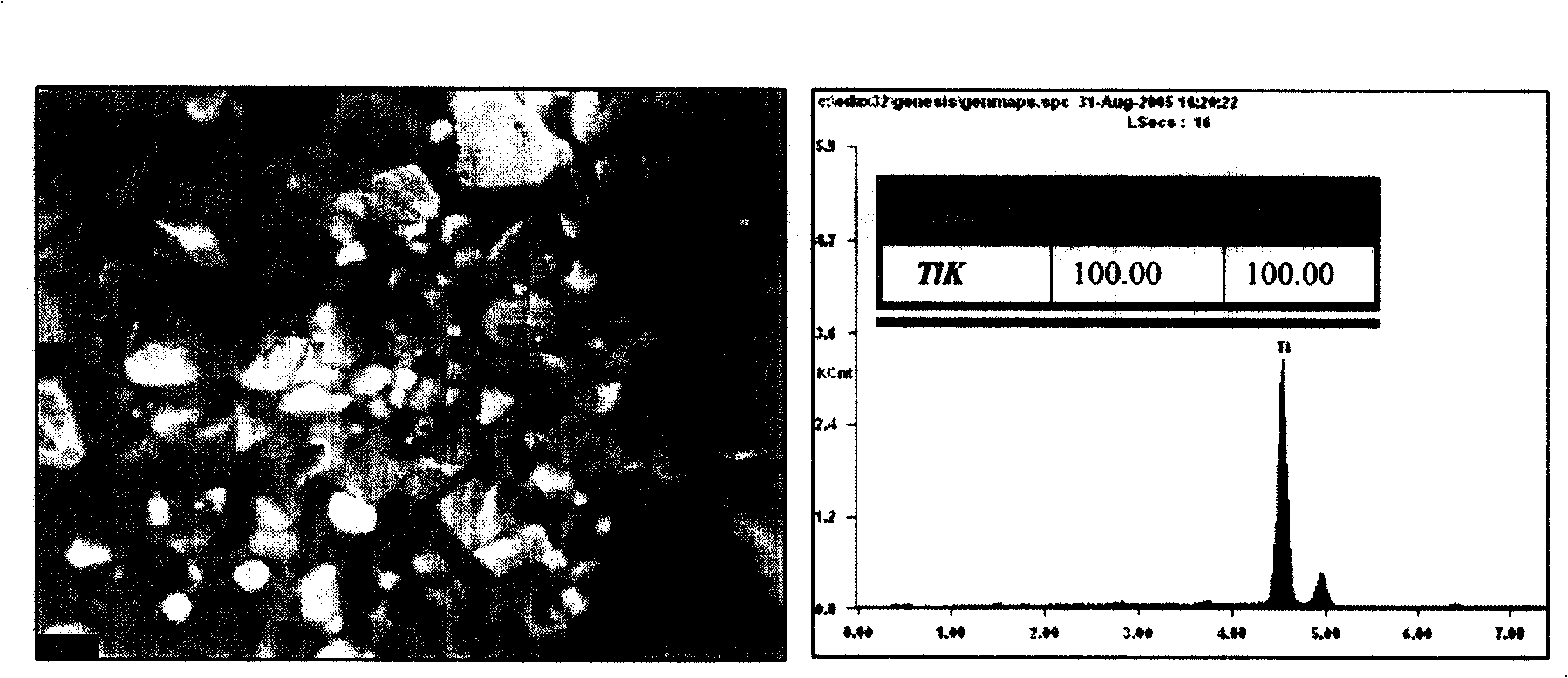

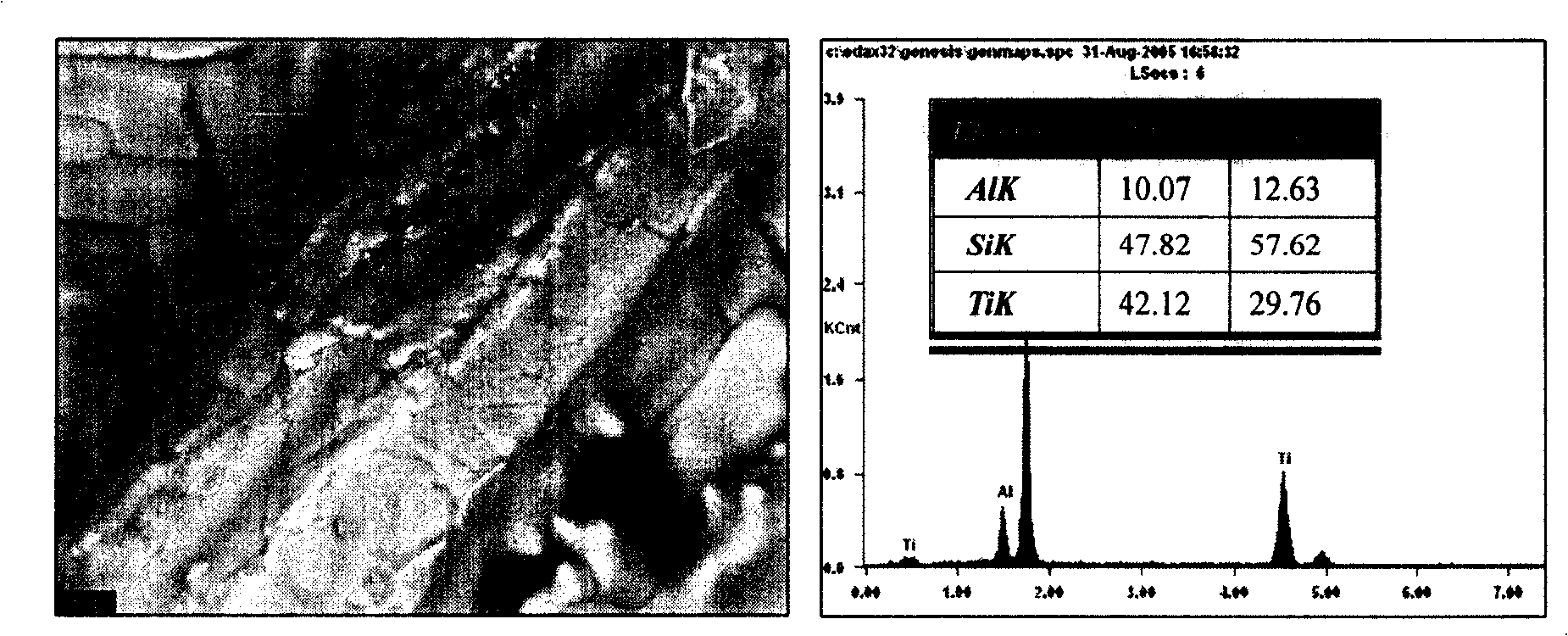

[0012] The reduction product prepared in this example-titanium metal such as figure 1 As shown, the prepared reduction product-aluminum silicon titanium alloy is as figure 2 Shown. An energy spectrometer was used to analyze the microstructure and components of the obtained product. The analysis results are as follows figure 1 , figure 2 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com