Three-tower energy-saving differential pressure alcohol distillation production system and technological process thereof

A process and atmospheric distillation technology, applied in the field of alcohol distillation, can solve the problems of large mutual influence, low product qualification rate, non-compliance with negative pressure and pressurized operation, etc., and achieve the effect of saving cooling water and steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

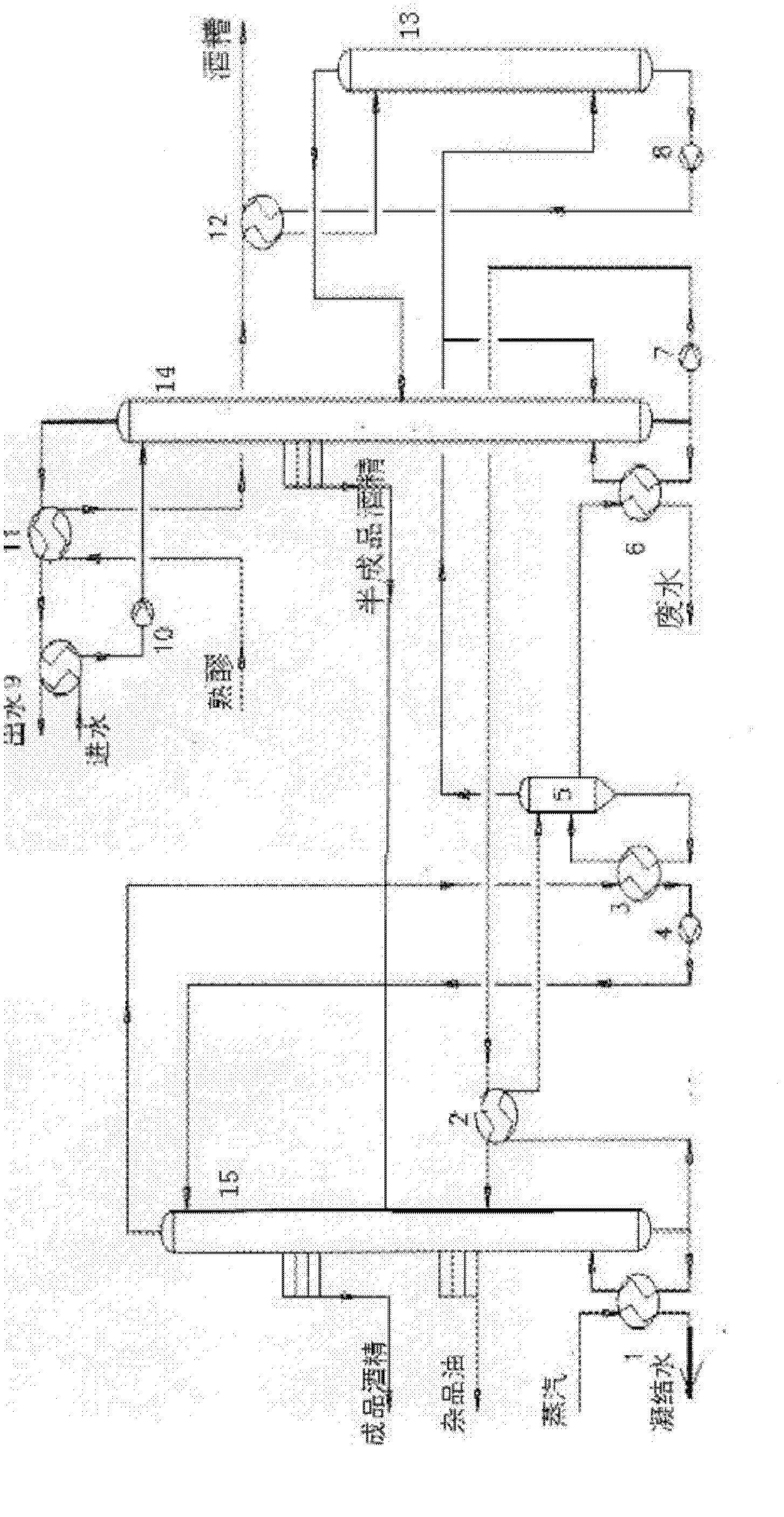

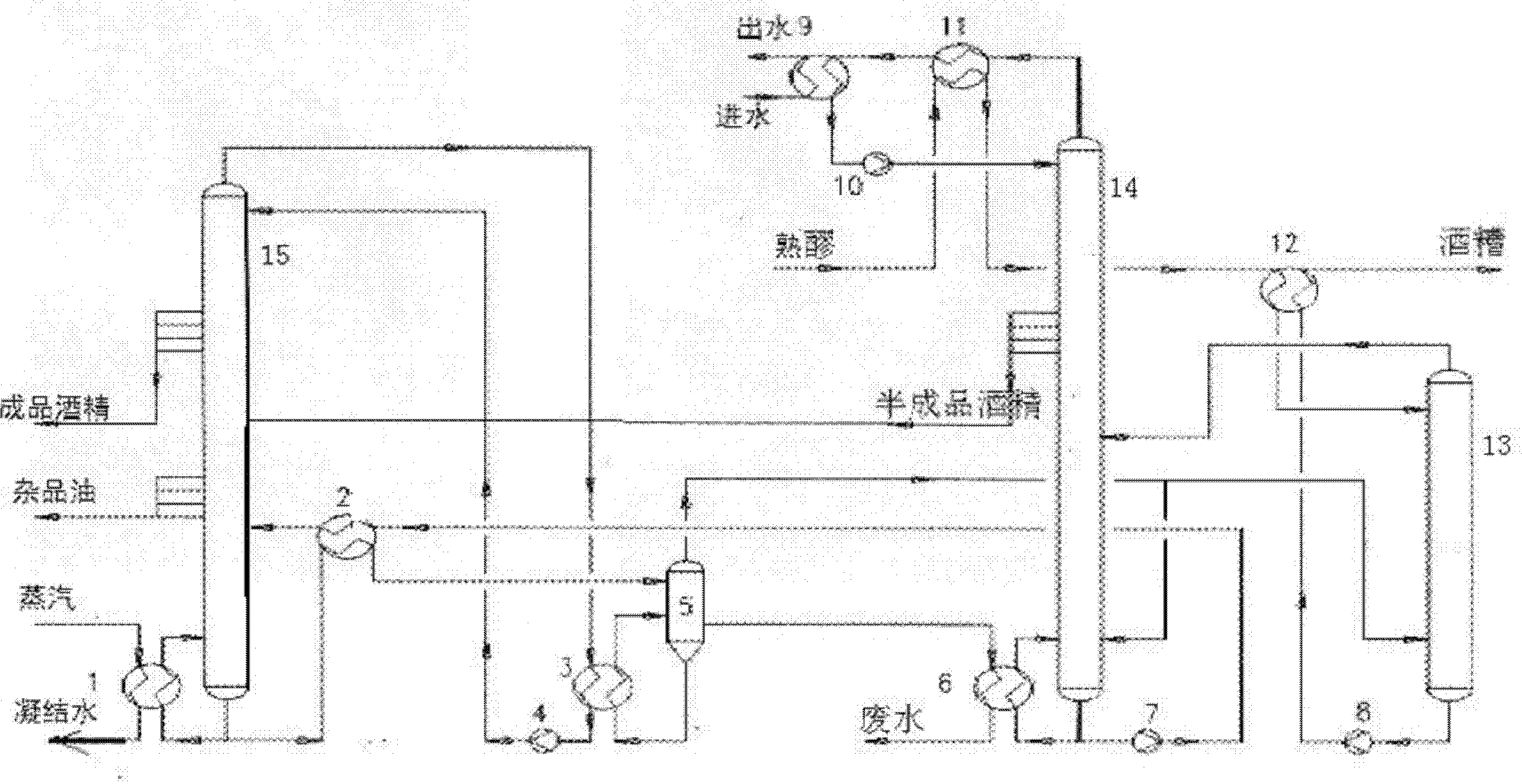

[0026] The three-tower energy-saving differential pressure alcohol distillation production system of the present invention is further described with reference to the accompanying drawings.

[0027] This production system mainly includes a beer tower 13, an atmospheric rectification tower 14, a distiller's grains pump 8, an atmospheric tower condenser 9, an atmospheric tower reflux pump 10, a beer tower wine gas preheater 11, and a fermented beer tower distiller's grains preheater 12 The two-tower atmospheric distillation system that forms, wherein it also comprises the pressurized rectification system that is made up of pressurized rectification tower 15 and pressurized auxiliary equipment; Pressurized auxiliary equipment comprises pressurized tower reboiler 1, pressurized rectification Tower alcohol preheater 2, steam generator 3, pressurized rectification tower reflux pump 4, vapor-liquid separator 5, atmospheric rectification tower reboiler 6, pressurized rectification tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com