Method for processing cast copper cooling wall of blast furnace

A technology of cast copper cooling stave and processing method, applied in the direction of cooling device, etc., can solve the problems of high production cost, poor metallurgical bonding strength, large geometric thickness of cast copper cooling wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

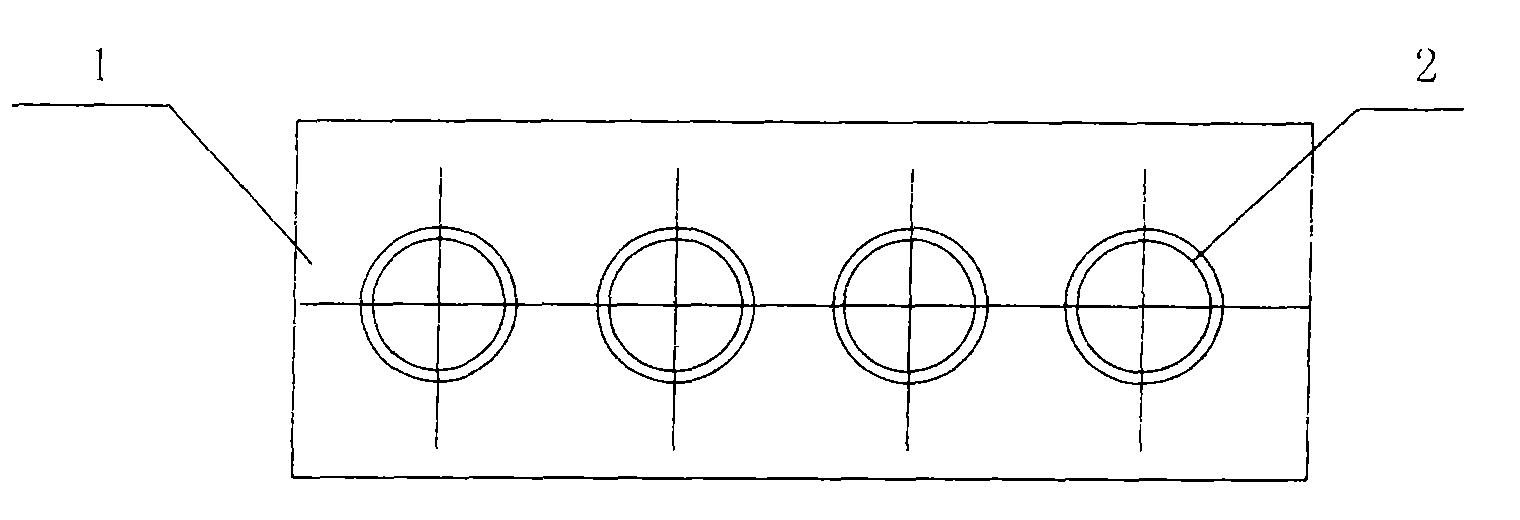

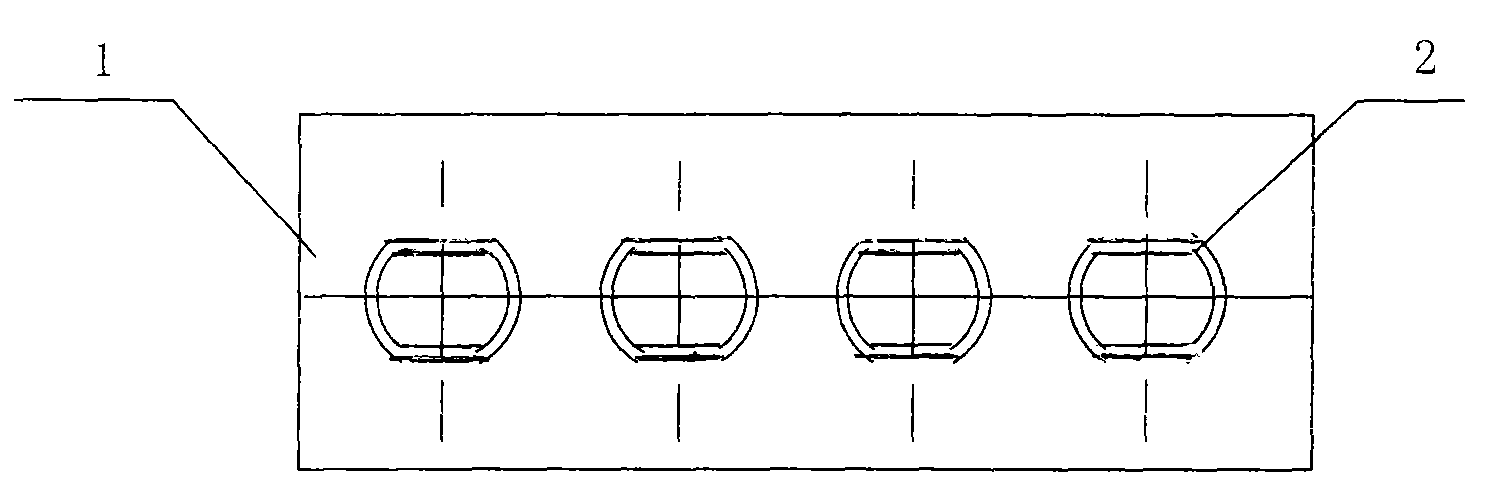

[0022] above figure 2 The disclosed structure is that of one embodiment of the present invention.

[0023] In the figure, 1 is the wall body of the cooling wall; 2 is the cooling pipe.

[0024] refer to figure 2 , during the implementation, the round steel pipe can be rolled and bent through the pipe bending machine, using a special mold, such as figure 2 The shape of the flat tube shown is put into the sand mold for casting. The processed flat cooling pipe is a meandering "serpentine" single pipe, and may also be composed of multiple (such as four) parallel single pipes. The material selected during processing can also be copper pipe or alloy pipe except steel pipe, and the specific implementation method is the same. The present invention is also applicable to the copper cooling stave of the rolling hole, that is, the cooling effect of the shape of the flat hole is better than that of the shape of the round hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com