Method for producing high purity 2-hydroxy-3-naphthoic acid

A naphthoic acid, high-purity technology, applied in the production field of high-purity 2-hydroxy-3-naphthoic acid, can solve the problems of reducing 2-naphthol, limited effect, waste of water resources, etc., to reduce the cooling time and improve the effect , Reduce the effect of cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

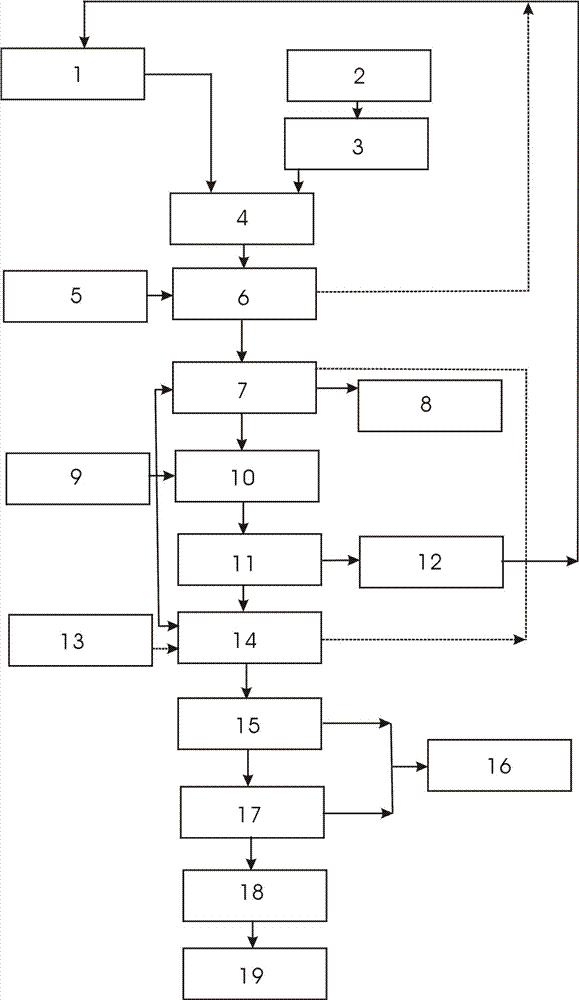

[0007] Now refer to the attached figure 1 , illustrate as follows in conjunction with embodiment: a kind of production method of high-purity 2-hydroxyl-3-naphthoic acid of the present invention comprises 2-naphthol metering tank 1, liquid caustic soda storage tank 2, liquid caustic soda metering tank 3, Salt forming reaction pot 4, carbon dioxide 5, carbonization kettle 6, resin separation 7, resin solid waste 8, dilute sulfuric acid 9, neutralization 10, pressure filtration 11, filter cake distillation 12, 8% sodium hydroxide 13, resin adsorption 14, Acid analysis 15, sewage treatment workshop 16, centrifugal dehydration 17, air drying 18 and high-purity 2-hydroxy-3-naphthoic acid finished product 19. The liquid caustic storage tank 2 is connected to the liquid caustic metering tank 3 downwards, the liquid caustic metering tank 3 is connected to the salt-forming reaction pot 4, and the 2-naphthol metering tank 1 is also connected to the salt-forming reaction pot 4 simultaneou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com