Rectification energy-saving new process

A new process and refined technology, applied in fractionation, petroleum industry, biological raw materials, etc., can solve the problems of high energy consumption, waste of heat energy and cooling water, unused gas phase residual heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below by example the present invention is further described:

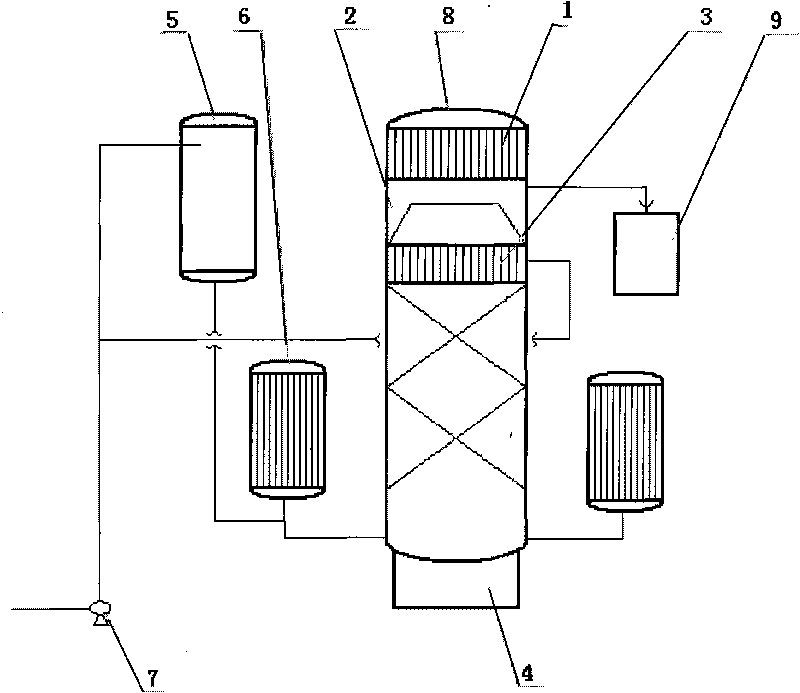

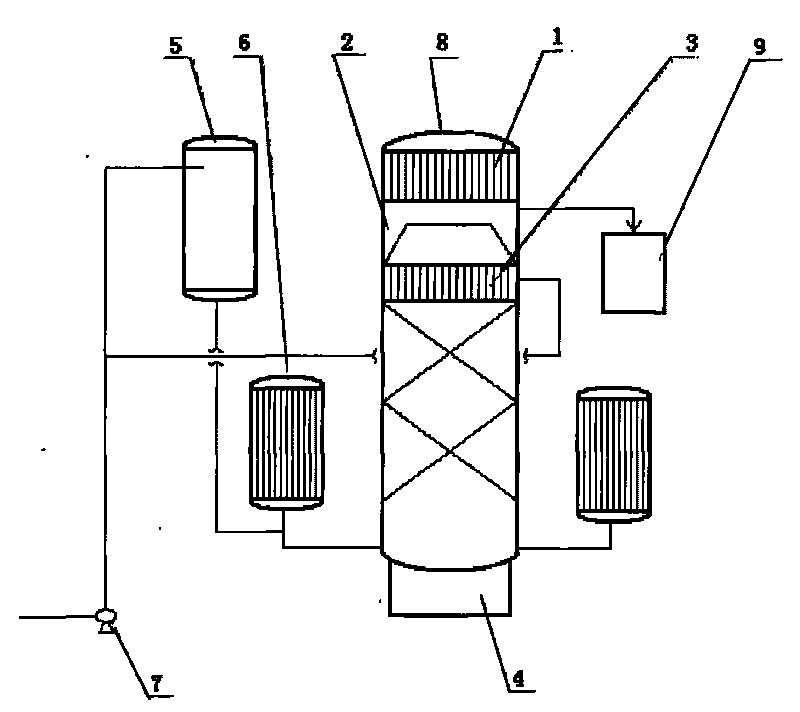

[0012] The gist of the present invention is that it relates to a new rectification and energy-saving process in the biodiesel production process. This process contains at least one energy-saving refining device. The structure of the refining device is: a cooler (1), a discharge tray (2), a replacement Heater (3), asphalt storage (4), preheater (5), reboiler (6), raw oil pump (7), refining tower (8), buffer tank (9); it is characterized in that the first During pot refining, the raw oil enters the preheater (9) through the raw oil pump (7), preheats the raw oil to 120°C, enters the reboiler (6) for vaporization, and then connects to the refining tower for vaporization and refining; from the second At the beginning of the pot, the raw material oil can be directly transported to the heat exchanger (3) in the refining tower through the feed pump (7), and the raw material oil is preheated to 120°C by using the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com