Low-grade heat flow prime motor, power generating system and method thereof

A power generation system, low-grade technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of underutilized heat energy, increased cost, increased environmental pollution and water resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

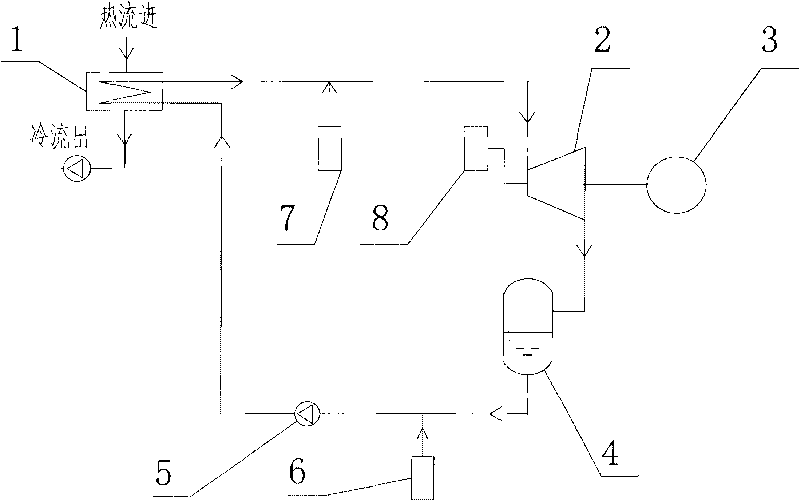

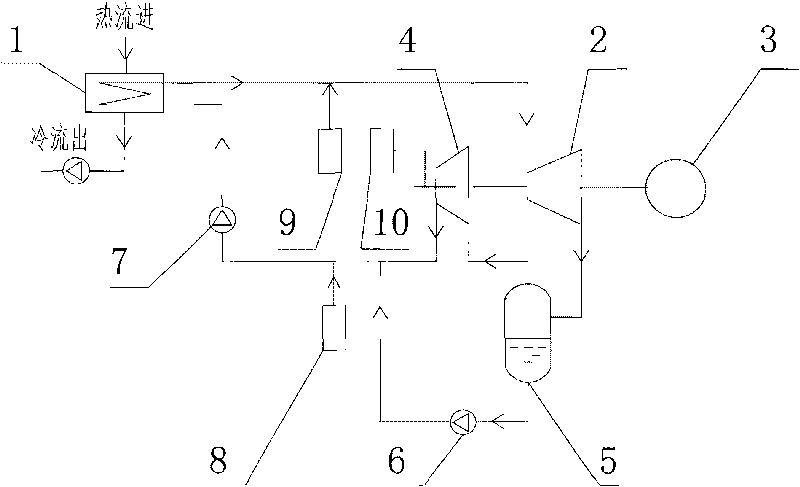

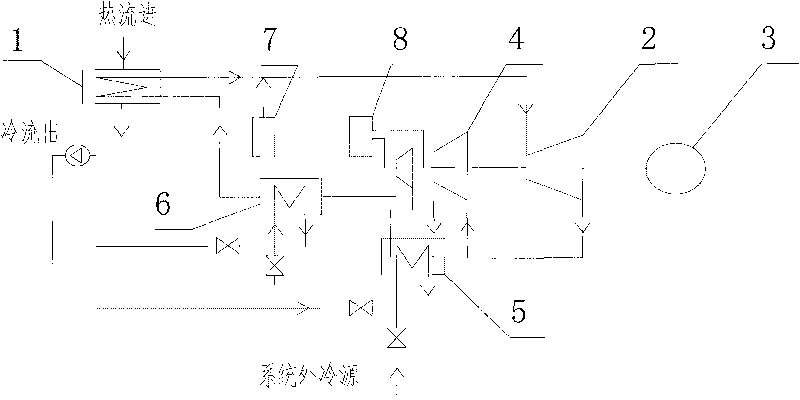

[0139] Below in conjunction with accompanying drawing, the present invention is further described:

[0140] see Figure 19 : This picture shows the second basic cycle prime mover, using low boiling point medium such as carbon dioxide gas in the heat flow boiler 1 tube side, the high pressure and low temperature low boiling point medium absorbs the shell side heat flow heat and then gasifies itself, and enters the expansion work unit 2 for decompression Expansion, transforming pressure energy into kinetic energy to push the expansion work unit 2 to move and do work. Various working machines, such as compressors, can be driven through the output shaft of the expansion unit 2 and the transmission unit 3, and at the same time drive the compression unit 4 to the gaseous low boiling point For medium compression, an electric motor can also be set to drive the compression unit 4 separately. The temperature of the low-boiling-point medium that has done the work is reduced to the lique...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com