Fuel filter

A kind of technology of fuel filter and filter, which is applied in the direction of machine/engine, liquid fuel feeder, fuel heat treatment device, etc., can solve the problems of automobile electricity shortage, etc., and achieve the goal of alleviating electricity shortage and saving electric energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

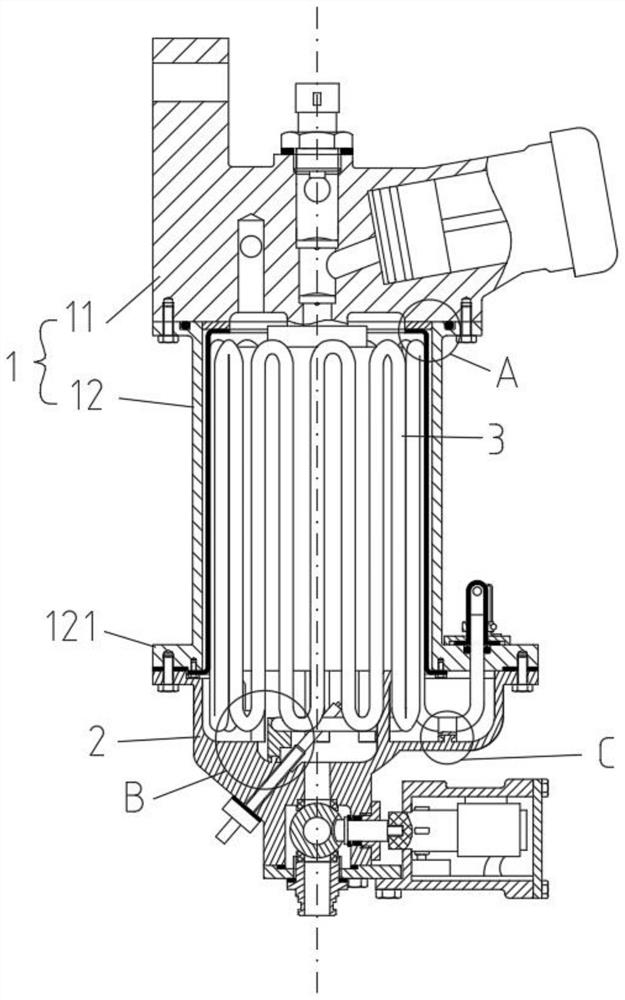

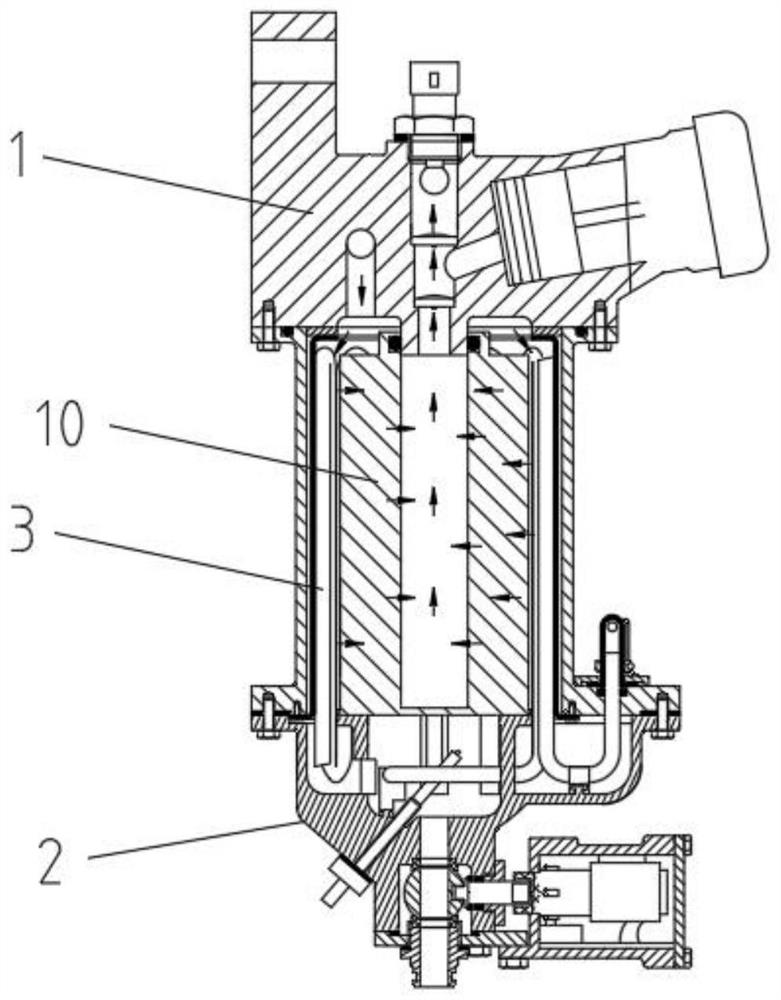

[0054] This embodiment provides a fuel filter, such as figure 1 with figure 2 As shown, the fuel filter includes a filter body 1 , a drain cup 2 and a heat exchanger 3 .

[0055] The filter body 1 can filter out impurities and water in the fuel, and the fuel flow route is as follows: figure 2 As shown by the arrow in the figure, after passing through the ring-shaped filter element 10, it is filtered from the outside to the inside layer by layer, and the finally filtered clean fuel flows out from the oil outlet channel on the central axis of the filter body 1, and the water filtered out by the filter element 10 and large-mass impurities sink into the water collection chamber of the drain cup 2, and the heat exchanger 3 extends from the drain cup 2 into the filter body 1, and the engine high-temperature coolant circulates in the heat exchanger 3.

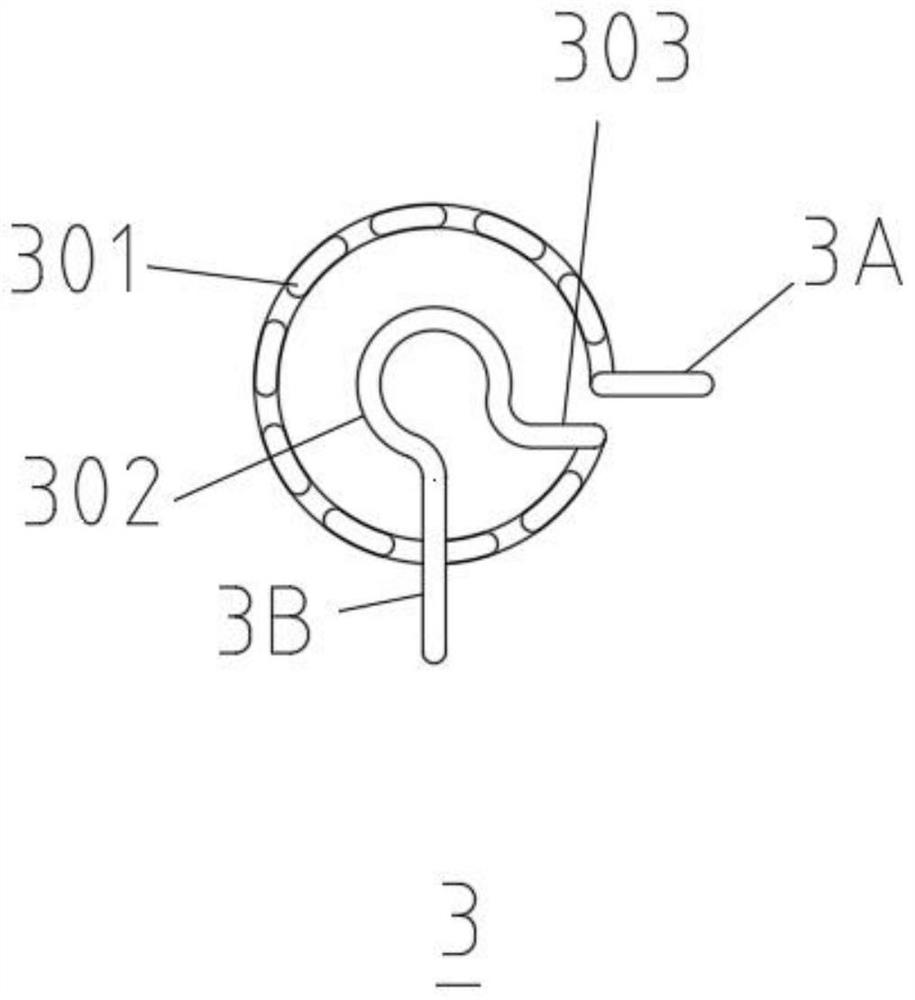

[0056] Such as Figure 1-Figure 5 , the heat exchanger 3 includes a water inlet section 3A, a water outlet section 3B and a hea...

Embodiment 2

[0073] This embodiment provides a fuel filter, such as figure 1 with figure 2 As shown, the fuel filter includes a filter body 1 , a drain cup 2 and a heat exchanger 3 .

[0074] The filter body 1 can filter out impurities and water in the fuel, and the fuel flow route is as follows: figure 2 As shown by the arrow in the figure, after being filtered layer by layer from the outside to the inside by the annular filter element 10, the finally filtered clean fuel flows out from the oil outlet channel on the central axis of the filter body 1, and the water filtered out by the filter element 10 and large-mass impurities sink into the water collection chamber of the drain cup 2, and the heat exchanger 3 extends from the drain cup 2 into the filter body 1, and the engine high-temperature coolant circulates in the heat exchanger 3.

[0075] Such as Figure 1-Figure 5 , the heat exchanger 3 includes a water inlet section 3A, a water outlet section 3B and a heat exchanger main body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com