Low-grade heat-flow prime mover, generating system and method thereof

A power generation system, low-grade technology, applied in the field of utilization of low-grade heat flow, can solve the problems of increasing environmental pollution, water resource consumption, and insufficient use of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Below in conjunction with accompanying drawing, the present invention is further described:

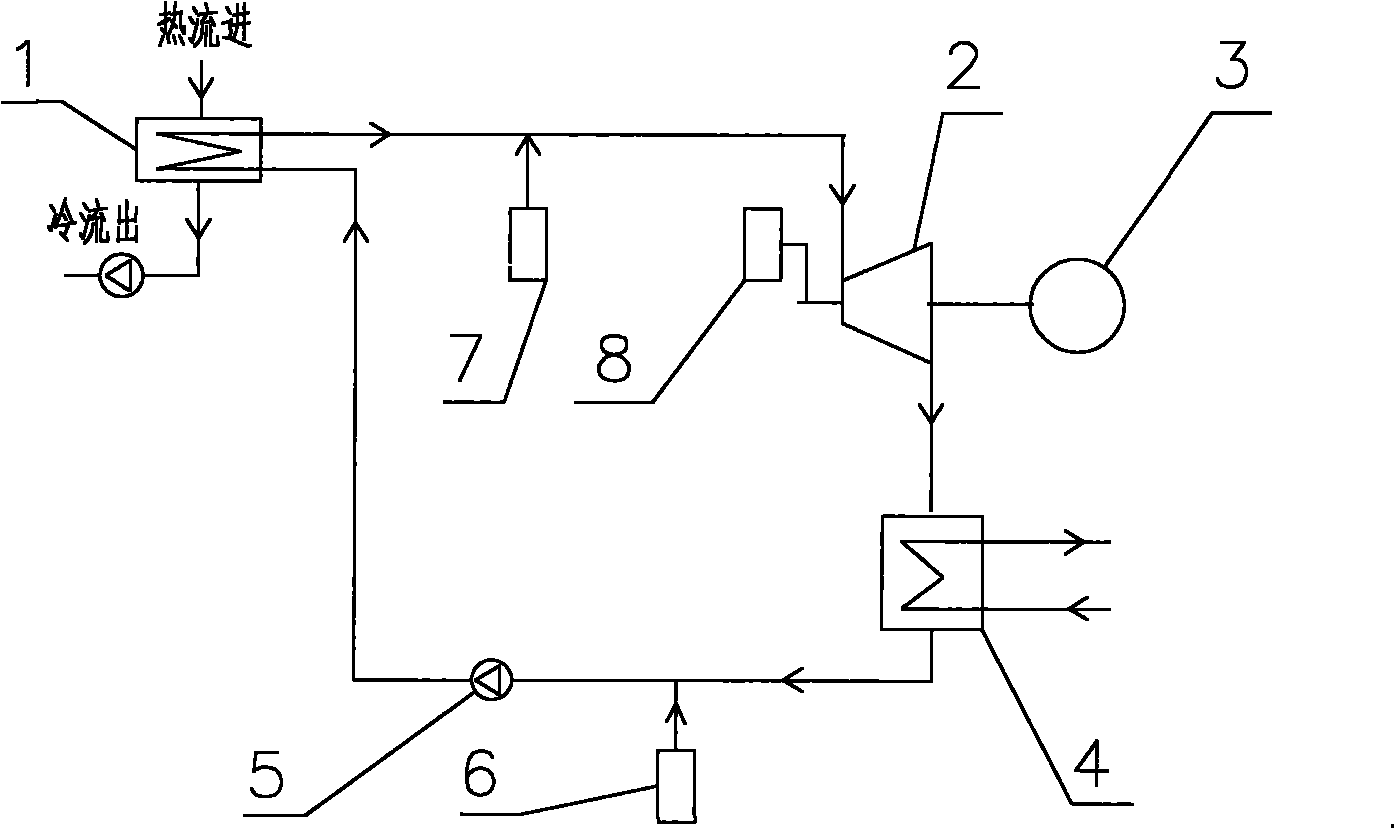

[0081] see figure 1 : The first type of basic power generation cycle, using one of the low boiling point medium such as dimethyl ether, in the tube side of the heat flow boiler unit 1, the high pressure and low temperature low boiling point medium absorbs the 200°C heat flow heat from the hot liquid side and then vaporizes at 120°C , enter the expansion work unit 2, decompress and expand, convert the pressure energy into kinetic energy to drive the moving parts of the expansion work unit 2 to do work, drive the power generation unit 3 to generate electricity through the power output shaft, and the temperature of the low boiling point medium after the work is reduced to the liquefaction temperature 40 ℃, enter the cooling unit 4 to be cooled and liquefied, and then pressurized to subcritical or critical or even supercritical pressure by the booster pump unit 5 and enter the tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com