Process for preparing carbocoal, coke tar and coal gas by treating bovey coal by suspending pyrogenation device

A suspension pyrolysis and lignite technology, applied in coking ovens, petroleum industry, direct heating and dry distillation, etc., can solve the problems of large-scale, energy consumption, water consumption, high investment costs, etc., to improve flammability, heat transfer Uniform and reduce heat consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

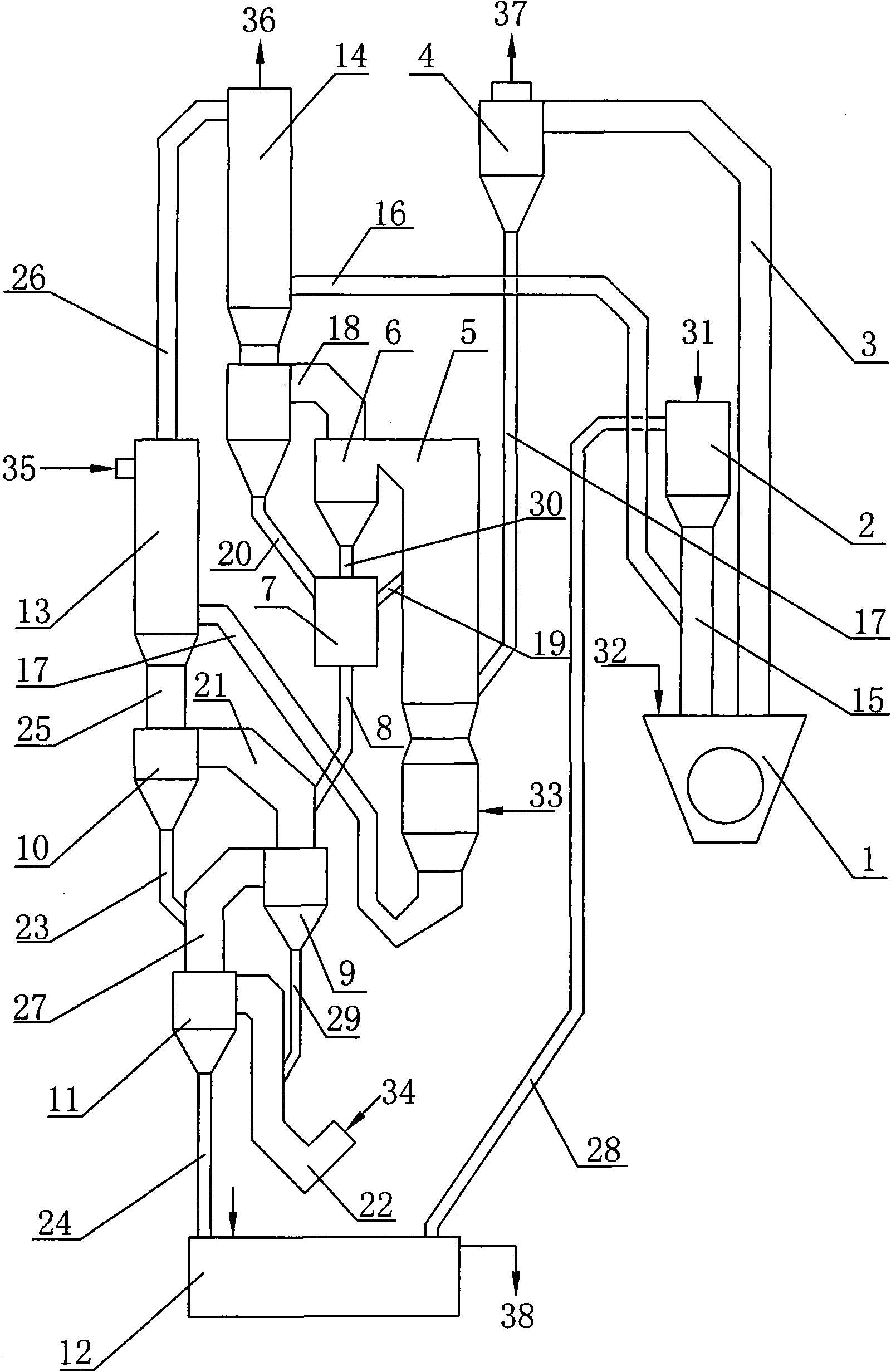

[0060] Gas heat-carrying lignite suspension pyrolysis device, including hammer dryer 1, drying heat generator combustion chamber 2, first pyrolysis cyclone separator 4, suspension pyrolysis furnace 5, second pyrolysis cyclone separator 6, and retention tank 7. First coke quenching cyclone separator 10 , second coke quenching cyclone separator 9 , third coke quenching cyclone separator 11 , semi-coke cooler 12 , oxygen source heater 13 and oil gas cooler 14 .

[0061] The outlet of the hammer dryer 1 is connected to the first pyrolysis cyclone separator 4 through the standpipe 3, and the smoke outlet of the combustion chamber 2 of the drying heat generator is connected to the smoke inlet of the hammer dryer 1 through the pipeline 15. The road 15 is connected to the gas outlet of the oil-gas cooler 14 through a branch pipe 16 . Suspension pyrolysis furnace 5 is a cylinder, divided into upper and lower chambers, with a constriction in the middle. The raw material lignite is added...

Embodiment 2

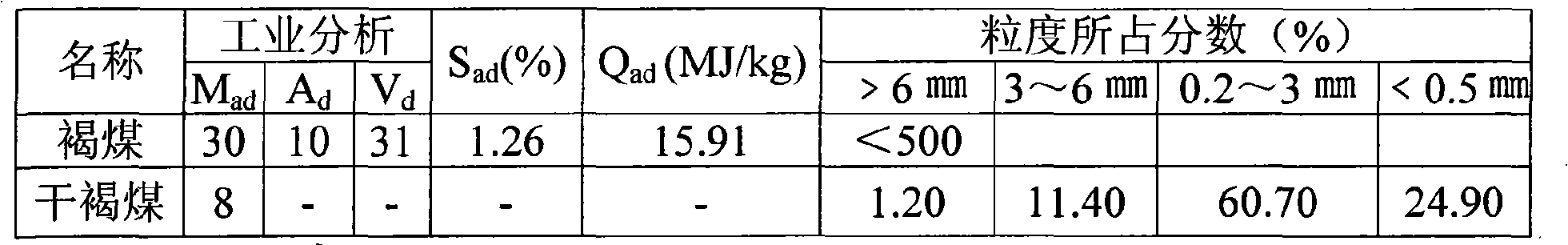

[0068] For lignite of the following composition and characteristics:

[0069]

[0070] Gejin test oil extraction rate is 35kg / t (dry coal)

[0071] The implementation steps and the result of adopting the processing device of the present invention are:

[0072]The lignite raw material is fed into the hammer dryer 1 to be pulverized into granular coal and fire powder, and is heated and dried by the 400°C hot flue gas generated by the combustion chamber 2 of the drying heat generator to remove most of the free water (outer water and inner water) ), exit the drier at 130°C, enter the cyclone separator 4 after staying in the standpipe 3 for several seconds, the separated exhaust gas enters the exhaust gas treatment system, and the solid particle coal with a residual moisture of 8% enters at a temperature of 130°C Inside the suspension pyrolysis furnace 5. Suspension pyrolysis furnace feeds appropriate amount of oxygen and coal gas for mixed combustion, heats dry coal to 600°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com