Technological method for producing cyclohexanone through dehydrogenation of cyclohexanol

A technology of cyclohexanone and cyclohexanol, which is applied in the direction of dehydrogenation preparation, separation/purification of carbonyl compounds, oxidation preparation of carbonyl compounds, etc., can solve the problems of high production cost and high energy consumption, and achieve reduction of energy consumption and cost, Energy-saving and consumption-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

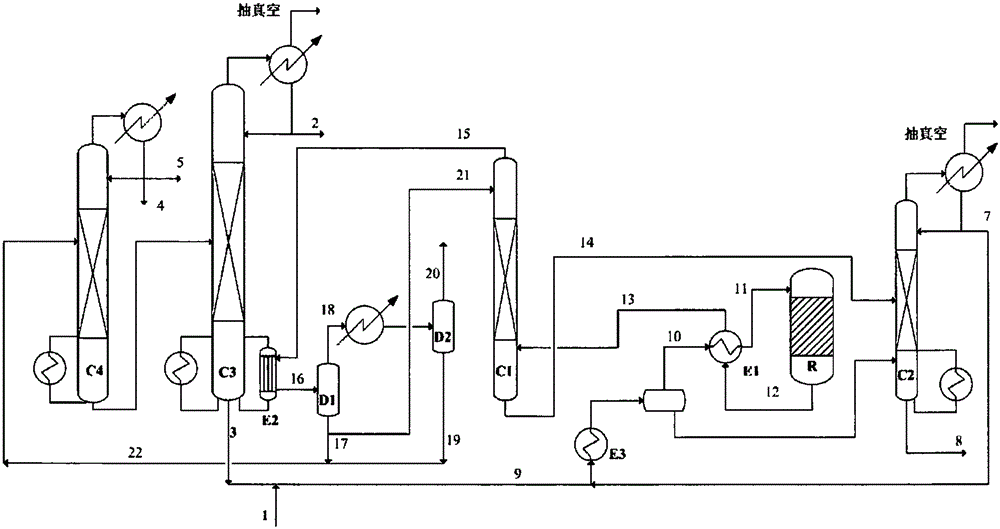

[0047] Take pure cyclohexanol as fresh raw material, according to the present invention figure 1 The flow process shown adopts the dehydrogenation product composition data (conversion rate 63.9%, selectivity 99.4%) given in Example 6 disclosed by patent WO98 / 10864, and the drying tower uses cyclohexene as the light key component; cyclohexanone The distillation column uses cyclohexanol as the key component, and its content is controlled to be less than 10ppm; the reaction gas deheavy separation tower uses phenol as the key component and its content is controlled to be less than 1ppm; the processing capacity is 12.8 tons of fresh cyclohexanol raw materials per hour After calculation, the operating conditions and energy consumption of each process are summarized in Table 1.

Embodiment 2

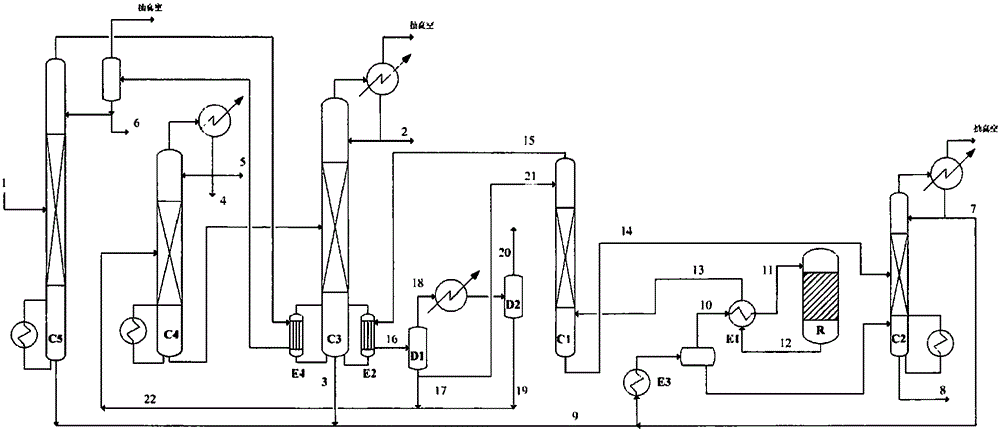

[0049] With the cyclohexanol that contains 500ppm methyl cyclopentanol as raw material, according to the present invention figure 2 As shown in the flow process, the dehydrogenation product composition data (conversion rate 63.9%, selectivity 99.4%) given in Example 6 disclosed by the patent WO98 / 10864 is adopted, and the cyclohexanol lightening tower uses methylcyclopentanol as the light key Components, control the content of methylcyclopentanol in the cyclohexanol raw material after distillation to be less than 50ppm; the reaction gas deheavy separation tower uses phenol as the key component and controls its content to be less than 1ppm; the drying tower uses cyclohexene as the light key Components: The cyclohexanone distillation tower uses cyclohexanol as the key component, and its content is controlled to be less than 10ppm. The processing capacity is calculated based on 12.8 tons of fresh cyclohexanol raw material per hour, and the operating conditions and energy consump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com