Water moulding water-fluid pressure ratio system

A water-hydraulic, proportional technology, applied in the field of plastic hollow injection molding production equipment, can solve the problems of low pressure and flow technical indicators, large and heavy equipment, low system efficiency, etc., to improve molding capacity and product quality, accurate pressure real-time computer control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

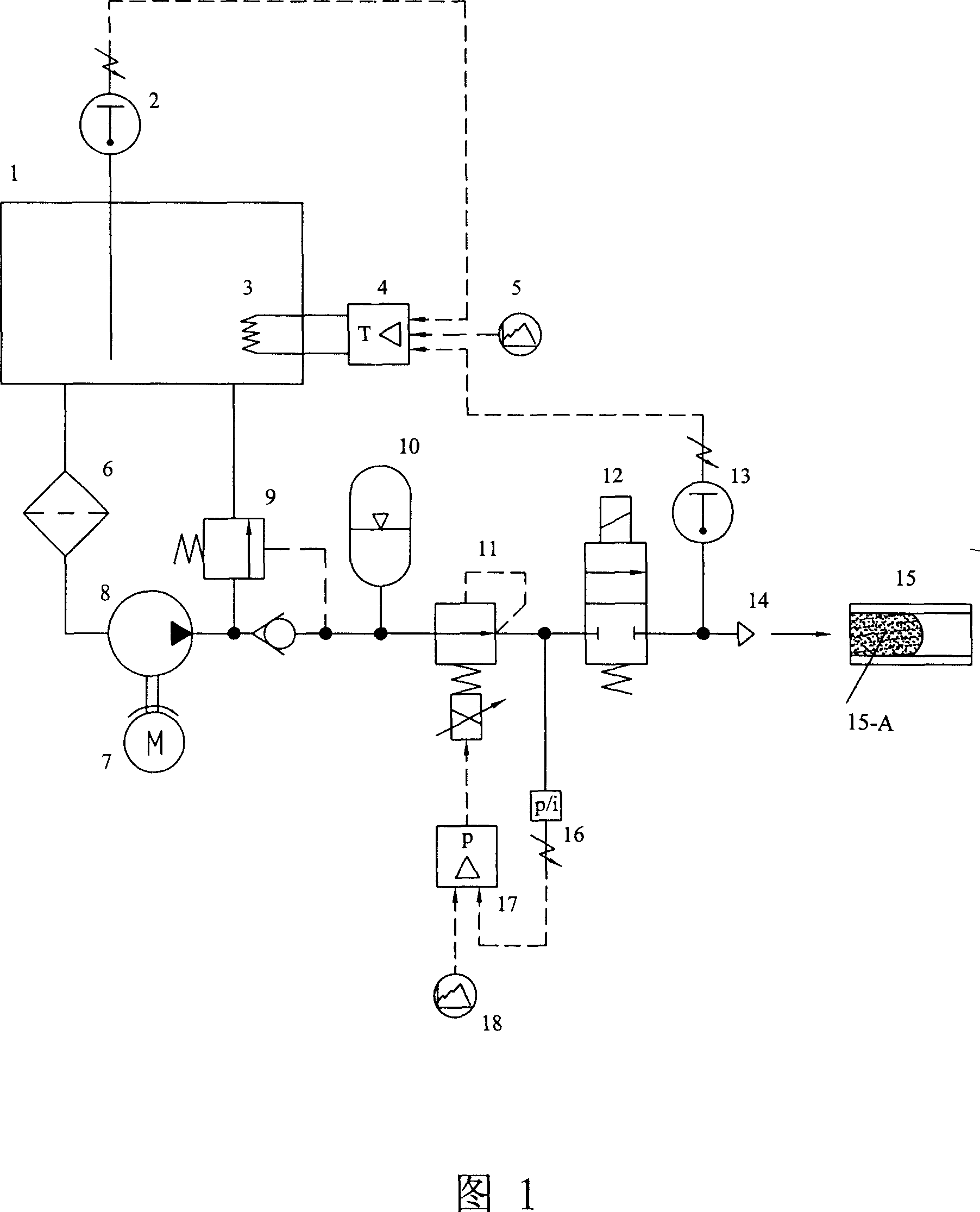

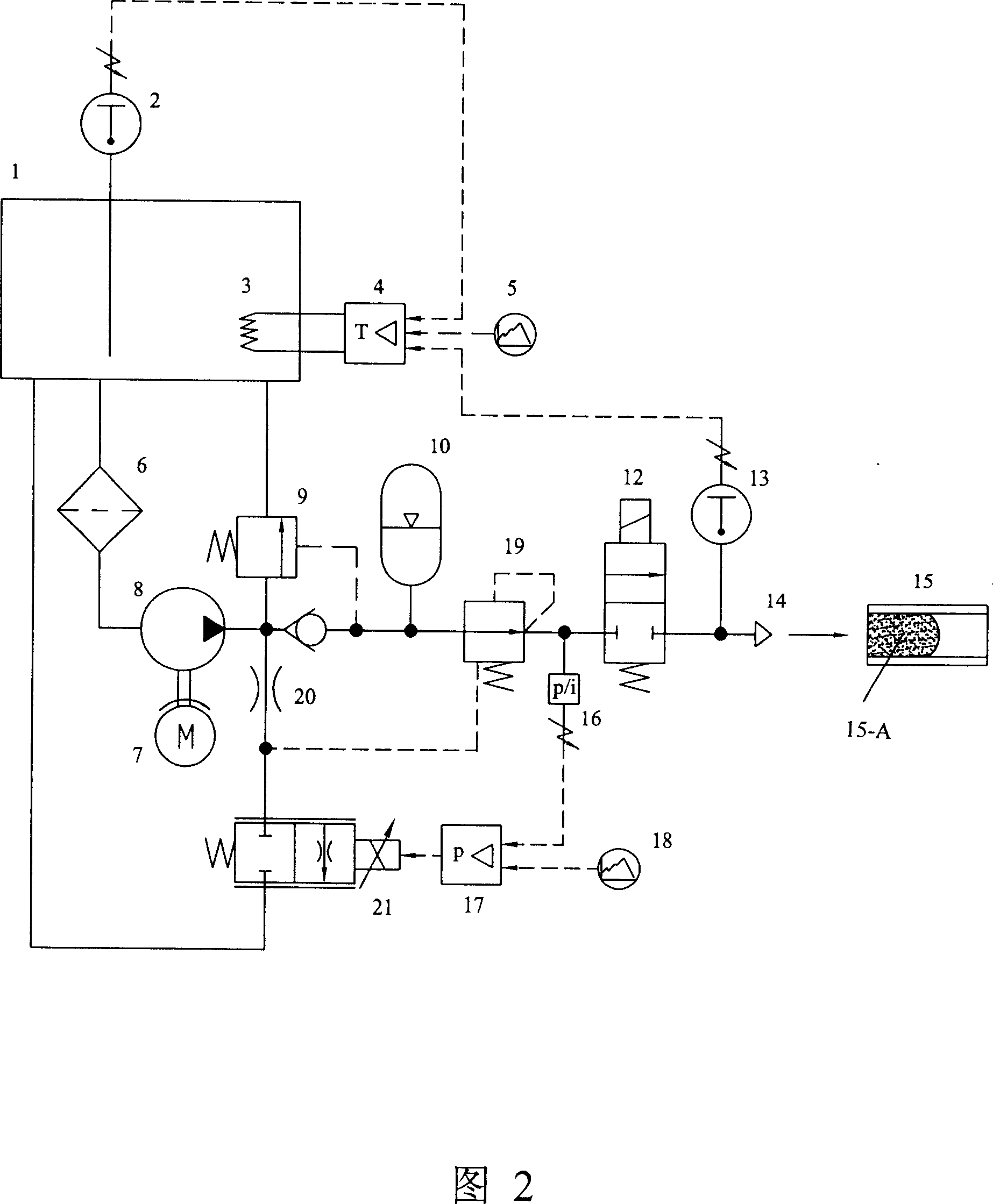

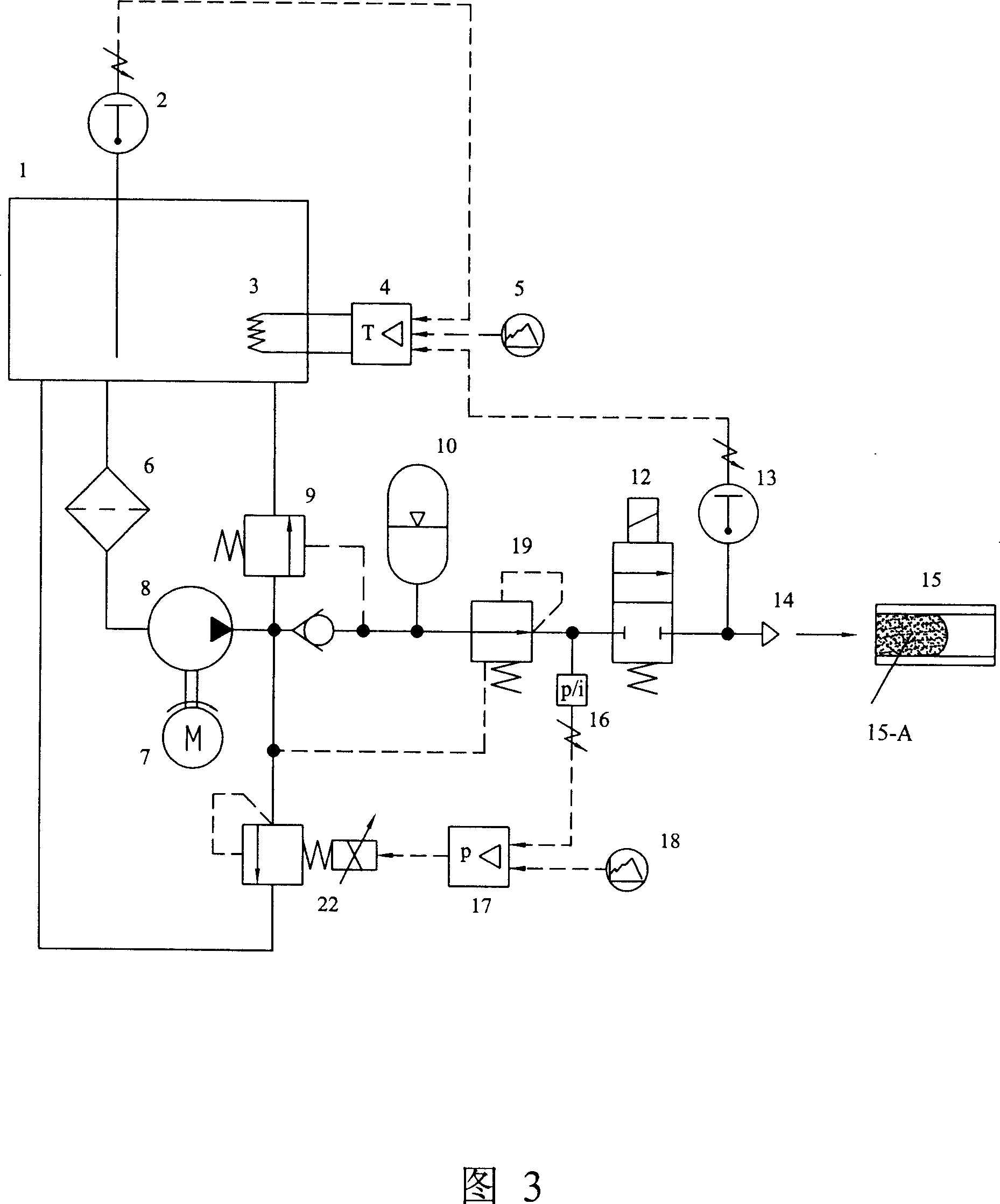

[0033] The process of water-assisted injection molding includes 1) boosting the pressure of the water hydraulic system to the initial pressure of water injection; 2) the stage of maintaining the initial pressure before water injection starts; 3) the water injection process, the injection water pressure rises according to the pressure curve of the injection pressure control command 18 to high pressure; 4) In the stage of high pressure holding and cooling, small flow of water is injected to compensate the cooling shrinkage of the plastic melt; 5) Pressure reduction and drainage; 6) Mold ejection, intermittent work.

[0034] Referring to Figure 1, the first embodiment of the water-assisted forming water hydraulic proportional system includes a temperature-controlled water tank 1, a water tank temperature sensor 2, a heater 3, a water temperature controller 4, a water temperature control command 5, a filter 6, a motor 7, Water hydraulic pump 8, unloading overflow valve 9, accumulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com