Flat jet flow nozzle and special coating machine

A jet nozzle and flat technology, which is applied in the field of flat jet nozzles and special spraying machines, can solve the problems such as the effect and quality of spraying need to be further improved, the quality cannot be guaranteed, the adhesion density is low, etc. The effect of reduced labor intensity and high density of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

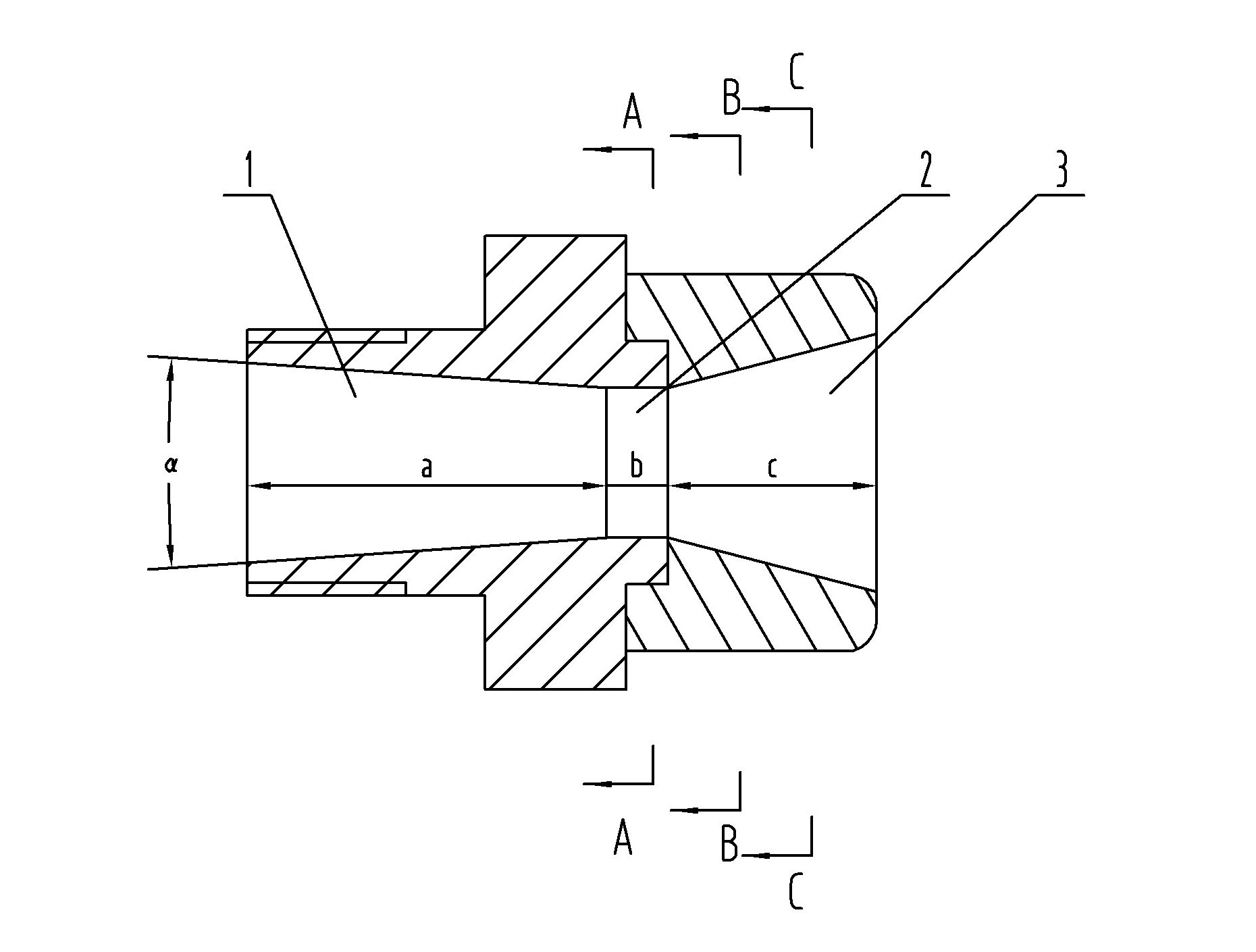

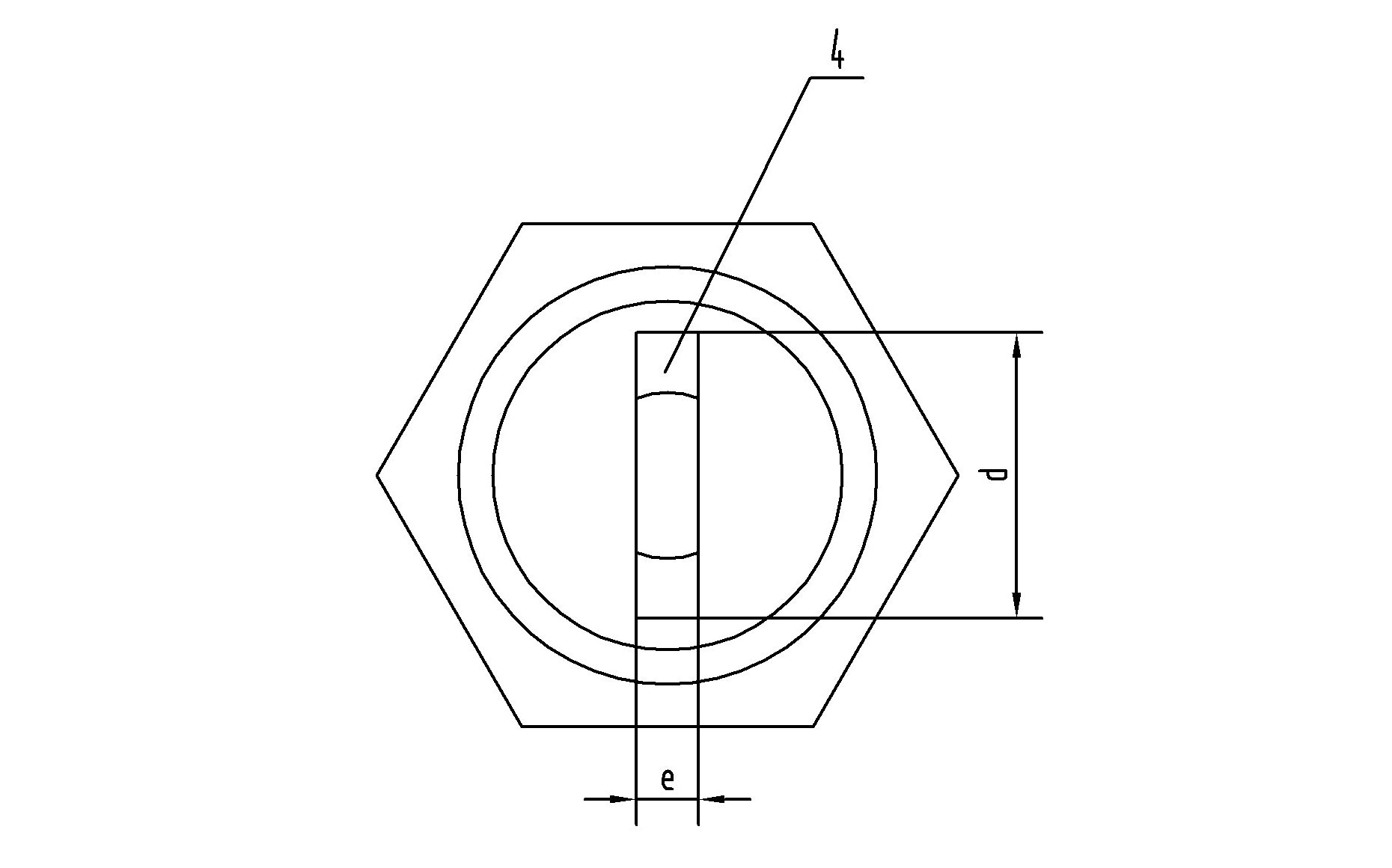

[0034] Embodiment one: see Figure 1 to Figure 5 , in the figure, the flat jet nozzle of the present invention includes shrinkage pipe section 1, throat pipe section 2 and diffuser pipe section 3 from left to right. The shrinkage pipe section 1 is hollow conical, and the range of the cone angle α is 30°≤α≤ 120°, the range of the length a of the shrinkage tube section 1 is 8mm≤a≤30mm, the throat section 2 is hollow cylindrical, the range of the length b of the throat section 2 is 1mm≤b≤4mm, and the inner cavity of the diffusion tube section 3 is The tail of the inner cavity of the throat section 2 gradually transitions to the flat hole 4 on the end face of the nozzle, the range of the length c of the diffuser section 3 is 3mm≤c≤12mm, and the range of the height d of the flat hole 4 is 3mm≤d≤12mm, the flat hole The range of the width e of 4 is 1.5mm≤d≤6mm; the flat hole 4 is an approximately flat rectangular hole; the shrinkage pipe section 1 and the throat pipe section 2 are in...

Embodiment 2

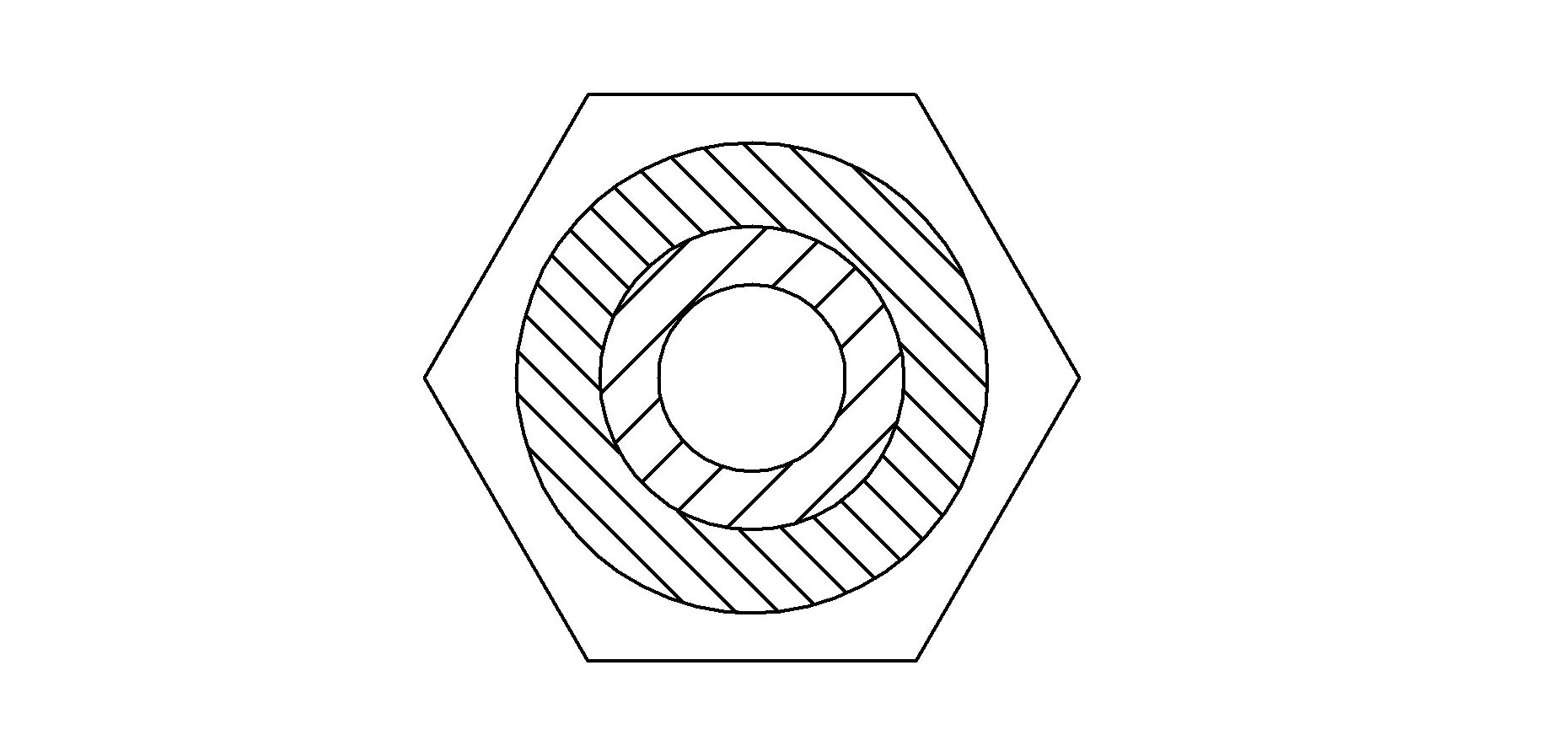

[0035] Embodiment two: see Image 6 , in the figure, the meanings of the same numbered parts in this embodiment and the first embodiment are the same and will not be repeated. The difference is that the flat hole 4 described in this embodiment is an approximately oblong circular hole.

Embodiment 3

[0036] Embodiment three: see Figure 7 , in the figure, the meanings of the same numbered parts in this embodiment and the first embodiment are the same and will not be repeated. The difference is that the flat hole 4 described in this embodiment is an approximately flat oval hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com