Method for preparing non-meat roast chicken powder and duck powdered meat from degreasing soybean meal

A technology of defatted soybean meal and non-meat source meat flavor powder, which is applied in the directions of food preparation, application, food science, etc., can solve the problems of low production efficiency, unsatisfactory, and many loss of flavor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

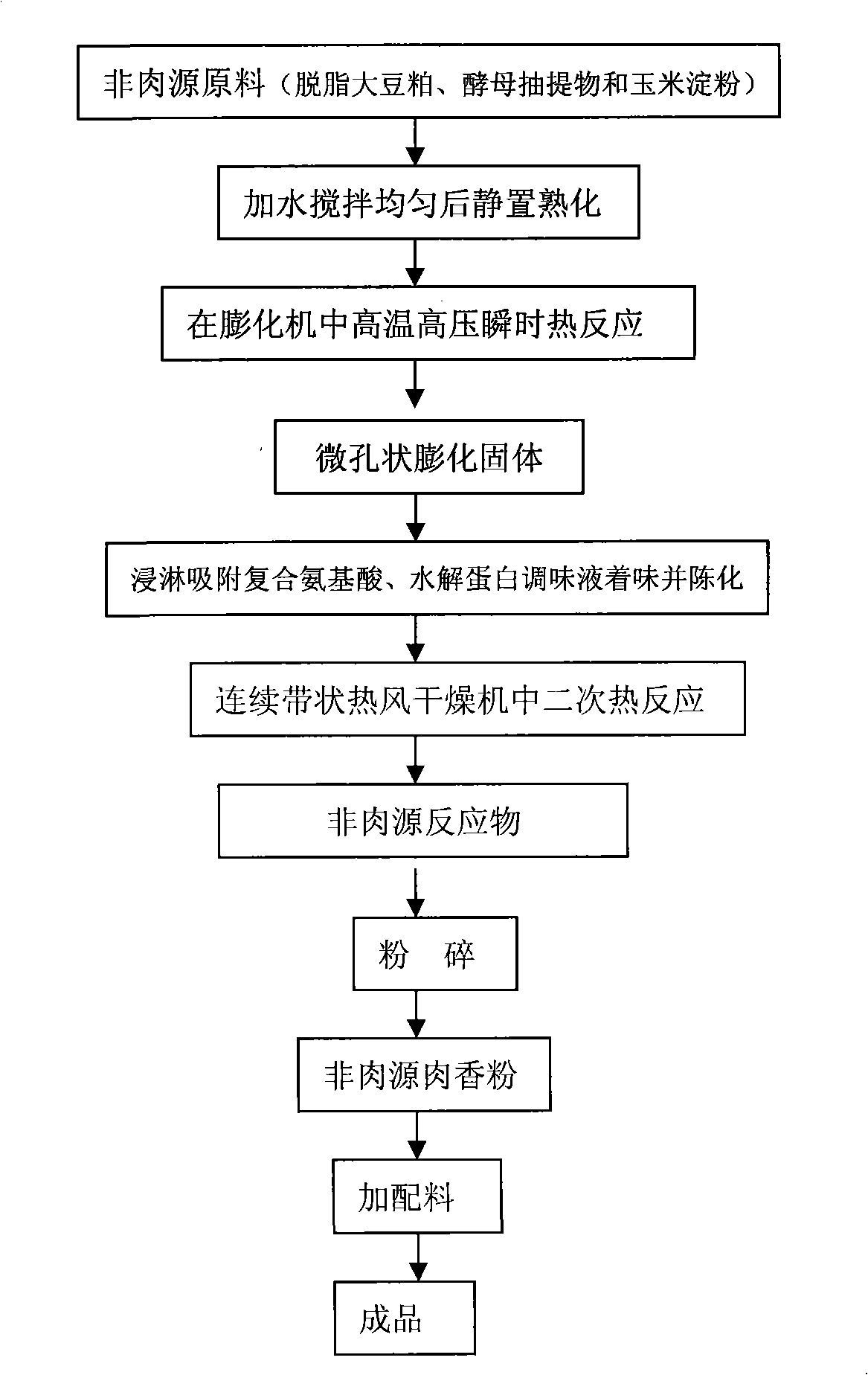

[0008] The specific embodiment of the present invention will be described in detail below in conjunction with the process flow diagram.

[0009] Select non-meat raw materials in weight percentage: 50-60% of defatted soybean meal, 10-15% of yeast extract, 8-12% of cornstarch and water as the balance. First, 50-60% of defatted soybean meal, yeast Mix 10-15% of the extract and 8-12% of cornstarch together, add water and stir evenly at 18-25°C, let it stand for 20-60 minutes, then put it into the extruder for reaction, the feeding speed is 350 -400r / min, at the speed of 140-160°C and 600-800r / min, the Maillard reaction is instantaneously completed to form a microporous puffed solid, and in weight percentage: microporous puffed solid 70-75%, Hydrolyzed vegetable protein 12-17%, compound amino acid 10-15%, the sum of which is 100% as raw materials, first mix the compound amino acid and hydrolyzed vegetable protein liquid evenly, then dip into the microporous puffed solid, taste and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com