Soy protein texturization meat-imitation product and preparation method thereof

A technology of soybean protein and soybean protein isolate, applied in the field of textured soybean protein imitation meat products and its preparation, and imitation meat products, to achieve the effect of obvious fiber filaments and good tissue structure

Inactive Publication Date: 2009-07-08

SOYBEAN TECH DEV RES CENT HEILONGJIANG PROV

View PDF0 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Soybean protein textured simulated meat developed by non-expanded extrusion technology uses soybean protein as the main raw material. The simul

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

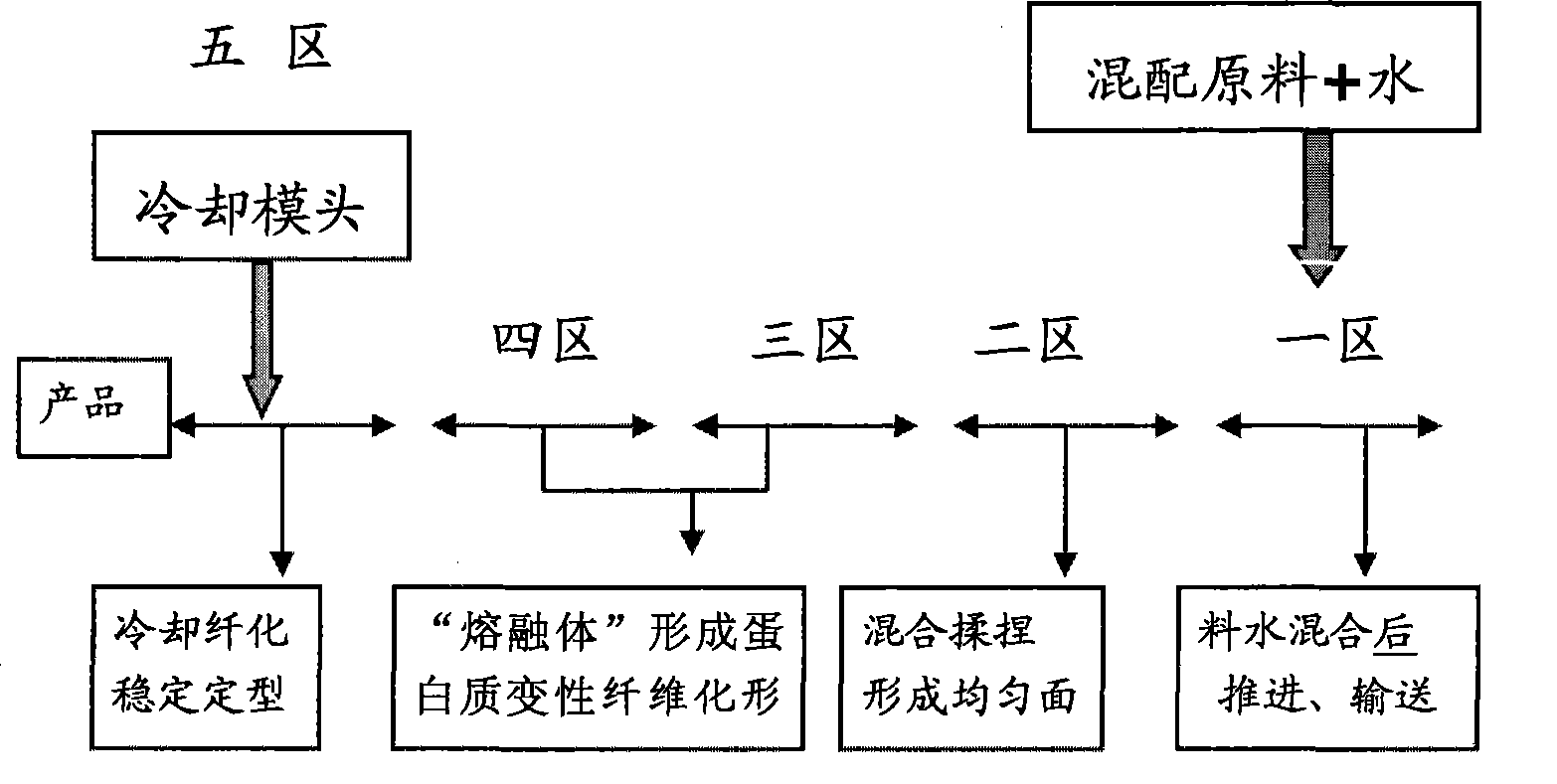

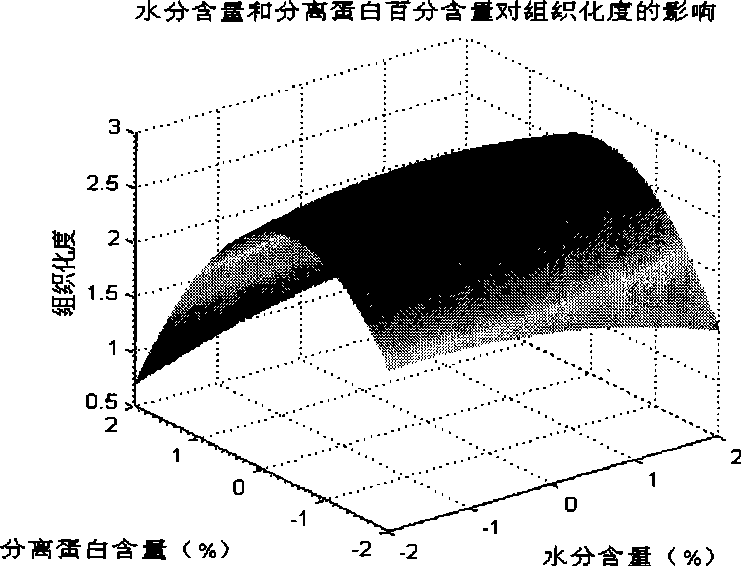

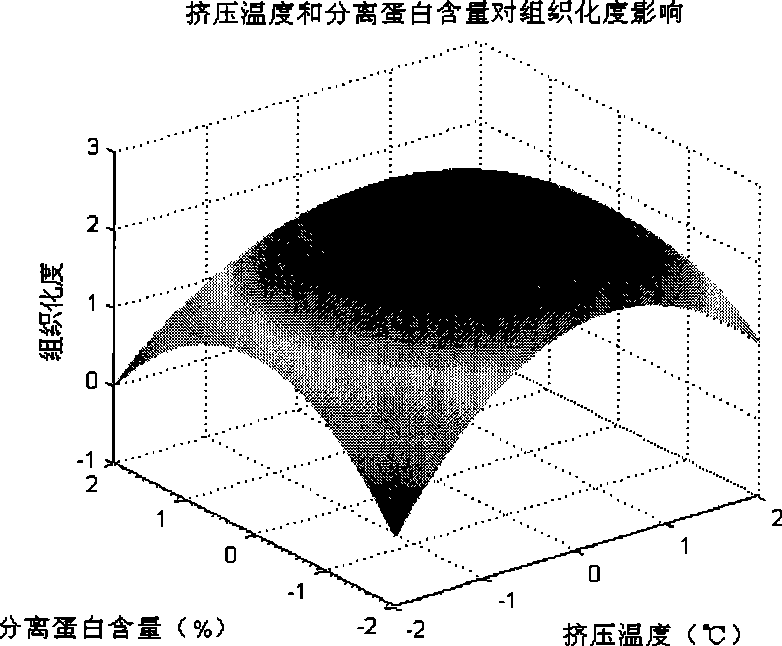

The invention discloses a method for preparing a texture soybean protein meat-like product. The invention considers the influence of the content of soybean separate protein, the water content of material, extrusion temperature and the rotating speed of a screw rod on texture degree and confirms the optimized parameter for processing the product as follows: the water content of the material is 48%-56%; the extrusion temperature of four areas is 150.8 DEG C to 153.5 DEG C; the rotating speed of the screw rod is 202-209rpm; and the content of separate protein is 34.5%-37.7%. Under the condition, the product has good tissue structure and obvious cellosilk and meets the requirement of the quality. The invention also optimizes the technical parameters of the methods for processing the prepared texture soybean protein meat-like product by pickling, marinating, coloring, baking and the like, and the processing methods can effectively overwhelm the bean flavor of fibrous soybean protein to ensure that the texture soybean protein meat-like product has the fragrance similar as roasted chicken and has the taste and the flavor similar as the quality of the roasted chicken in market at present.

Description

technical field [0001] The invention relates to a meat imitation product, in particular to a textured soybean protein imitation meat product and a preparation method thereof, belonging to the field of artificial food. Background technique [0002] Simulated food (also known as artificial food), that is, to simulate ordinary food into precious and rare food by scientific means. Simulated food is not made of chemical raw materials, it is based on the nutritional content of the imitated natural food, selects ordinary food containing similar ingredients as raw materials, and makes various simulated foods (Jia Jun, Ren Luquan, Cong Qian. Research on Bionic Food Engineering [J]. Grain and Oil Processing and Food Machinery, 2006(1): 84~89). [0003] In recent years, countries in the world have developed many nutritious and convenient foods in order to meet the needs of consumers. High-quality and cheap artificial food, such as artificial shark fin, artificial jellyfish skin, arti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23L1/305A23L1/20A23P1/12A23L33/185

Inventor 朱秀清李佳栋孙树坤江连洲孙莹杨耸孙志欣

Owner SOYBEAN TECH DEV RES CENT HEILONGJIANG PROV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com