Recombined sausage with salt roasted chicken flavor and preparation method of recombined sausage

A production method and salt-baked chicken technology are applied in the directions of food preparation, food ingredients as taste improvers, food science, etc., and can solve the problems of lack of processing technology and low added value for leftovers such as chicken bones and minced meat. The taste is uniform and delicious, the taste is uniform, and the effect is rich in nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

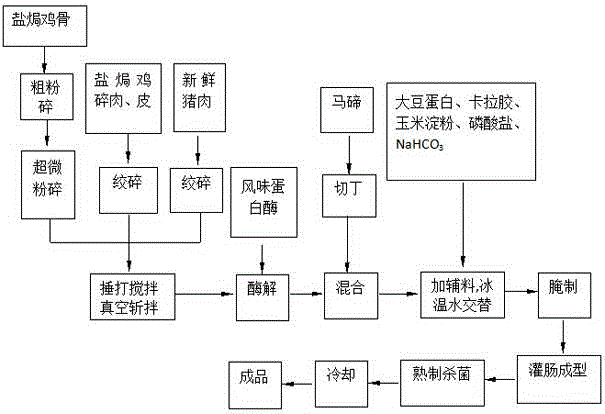

Method used

Image

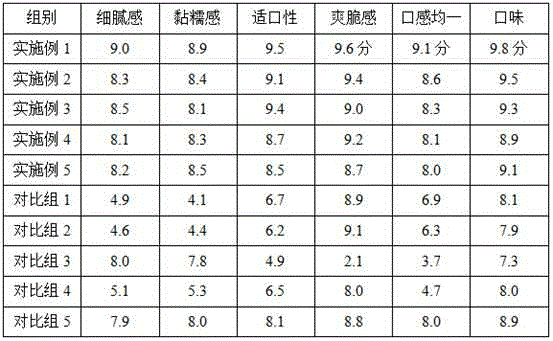

Examples

Embodiment 1

[0047] Example 1 Preparation of Recombined Sausage

[0048] The specific production steps for preparing the salt-baked chicken-flavored recombined sausage are as follows:

[0049] S1. Raw material pretreatment: Weigh 150g of salt-baked chicken bones, coarsely pulverize them with a high-speed pulverizer, and then pulverize them into a chicken bone paste of about 20 μm with a superfine pulverizer; weigh 450g of salt-baked chicken minced meat and put it into a meat grinder for grinding Crumble into a puree; weigh 300g fresh (frozen) pork, thaw the meat and cut into cubes, cut into about 1×1×1cm 3 The size of the cube, put it into a meat grinder and grind it into a meat paste;

[0050] S2. Vacuum chopping: Mix chicken bone paste, chicken paste and pork paste together and add 180g of water. After initial mixing, hammer and stir repeatedly with an iron hammer; put the hammered material into a vacuum chopping machine, and the vacuum 0.06kpa, under the condition that the slurry te...

Embodiment 2

[0060] Example 2 Preparation of recombined sausage

[0061] The specific production steps for preparing the salt-baked chicken-flavored recombined sausage are as follows:

[0062] S1. Raw material pretreatment: Weigh 100g of salt-baked chicken bones, coarsely pulverize them with a high-speed grinder, and then use an ultrafine grinder to grind them into a chicken bone paste of about 20 μm; weigh 350g of salt-baked chicken minced meat and put it into a meat grinder to grind Crumble into a puree; weigh 400g fresh (frozen) pork, thaw the meat and cut into cubes, cut into about 1×1×1cm 3 The size of the cube, put it into a meat grinder and grind it into a meat paste;

[0063] S2. Vacuum chopping: Mix chicken bone paste, chicken paste and pork paste together and add 170g of water. After initial mixing, hammer and stir repeatedly with a hammer; put the hammered materials into a vacuum chopping machine, 0.06kpa, under the condition that the slurry temperature is 6°C, chop and mix ...

Embodiment 3

[0073] Example 3 Preparation of Recombined Sausage

[0074] The specific production steps for preparing the salt-baked chicken-flavored recombined sausage are as follows:

[0075] S1. Raw material pretreatment: Weigh 200g of salt-baked chicken bones, coarsely pulverize them with a high-speed pulverizer, and then pulverize them into a chicken bone paste of about 20 μm with a superfine pulverizer; weigh 550g of salt-baked chicken minced meat and put it into a meat grinder for grinding Crumble into a puree; weigh 200g fresh (frozen) pork, thaw the meat and cut into cubes, cut into about 1×1×1cm 3 The size of the cube, put it into a meat grinder and grind it into a meat paste;

[0076] S2. Vacuum chopping and mixing: Mix chicken bone paste, chicken paste and pork paste together and add 190g of water. After the preliminary mixing, hammer and stir repeatedly with an iron hammer. 0.06kpa, under the condition that the slurry temperature is 4°C, chop and mix for 20min;

[0077] S3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com