A multi-channel differential reaction device

A differential reaction, multi-channel technology, used in measurement devices, material separation, analysis of materials, etc., can solve problems such as insufficiency, eliminate gas composition and flow errors, ensure gas feeding, and reduce experimental deviations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

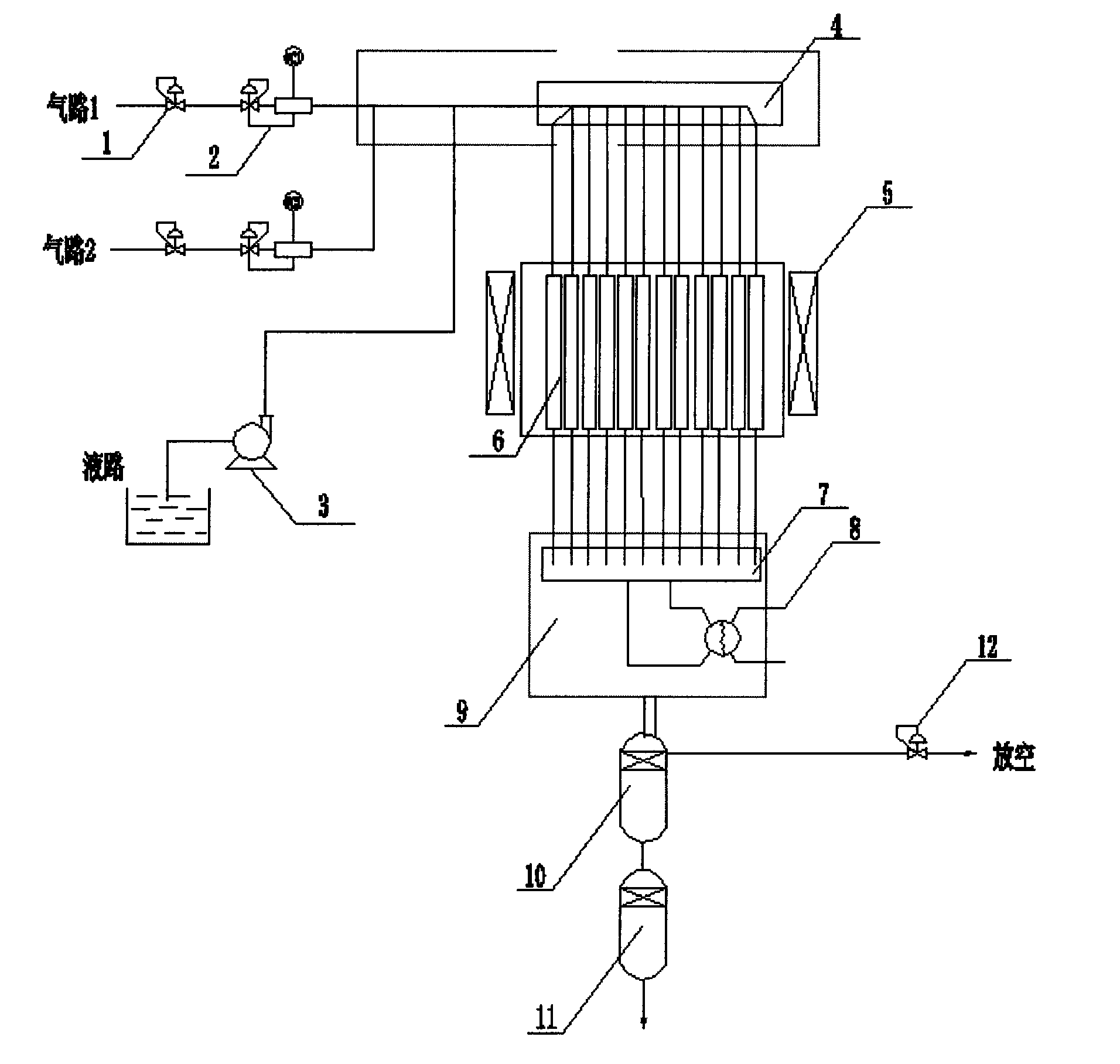

[0028] The multi-channel differential reaction device of the present invention is used to carry out six groups of parallel ethanol etherification reactions simultaneously, and samples from the six channels are successively taken respectively for on-line analysis.

[0029] H on the device 2 , N 2 , exhaust gas and cooling water inlet and outlet, connect the corresponding channels respectively, connect the exhaust gas to the vent pipe and ensure that the vent pipe is unobstructed. When the system valve is closed, the six reaction tubes are filled with ZSM-5 catalyst, and the catalyst loading is 1.000g, and the reaction tubes are installed on the device in sequence. Turn on H 2Air source, guaranteed H 2 The pressure is maintained at 2.50MPa±0.1MPa, and the pressure difference between the two paths is controlled to be consistent. Adjust mass flow meter setting N 2 Gas velocity 200mL / min, H 2 The gas rate is 80mL / min. After the system pressure and gas flow are stable, turn on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com