Superfine particles sampling device

A sampling device and particle technology, applied in the field of ultra-fine particle sampling devices, can solve the problems of inability to extract ultra-fine particles, unsatisfactory cooling efficiency of sampling tubes, and inability to guarantee the accuracy of test response time, etc., and achieve excellent cooling effect and continuous sampling. , the effect of reducing the overall temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with example and accompanying drawing, the present invention is described in further detail.

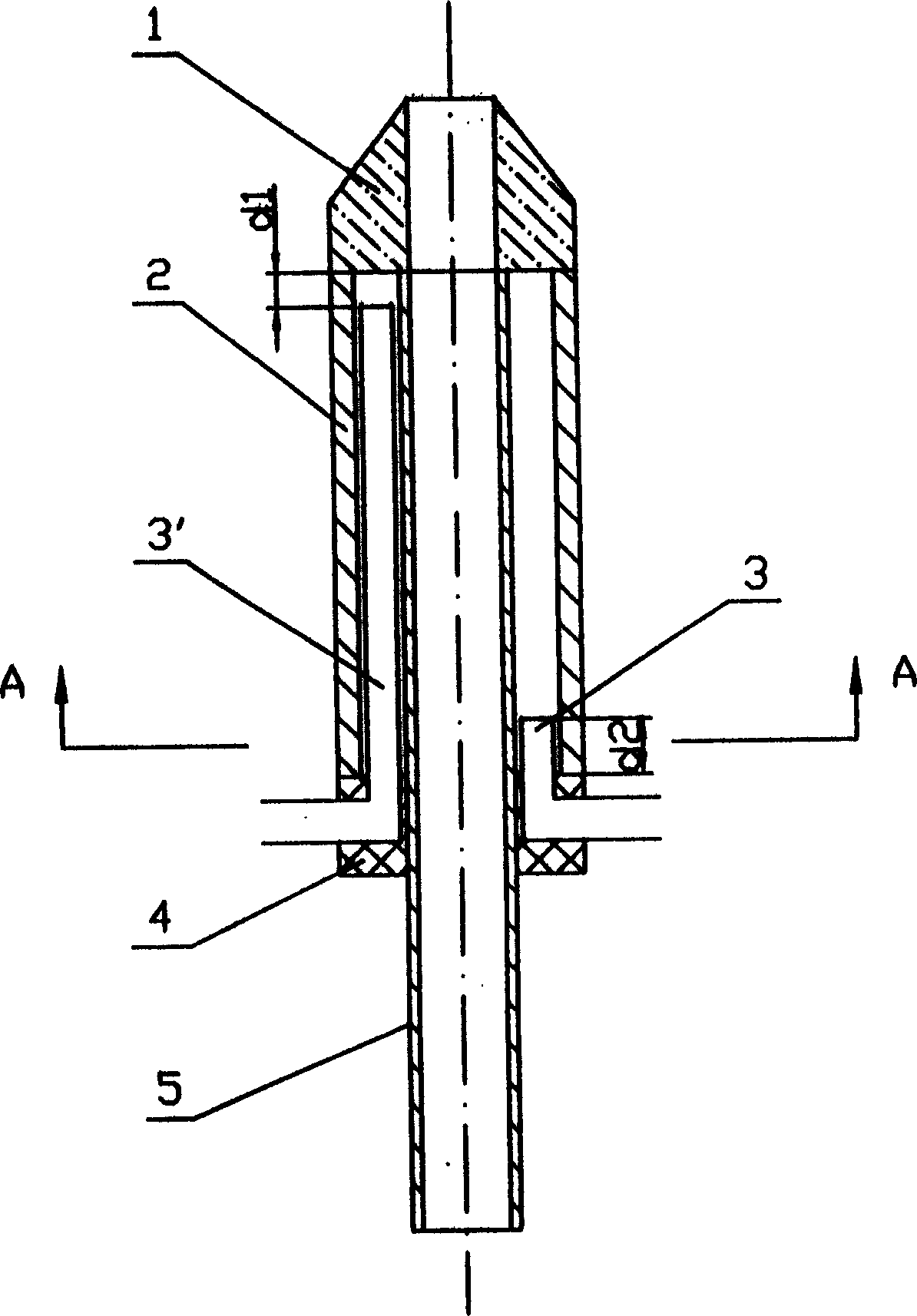

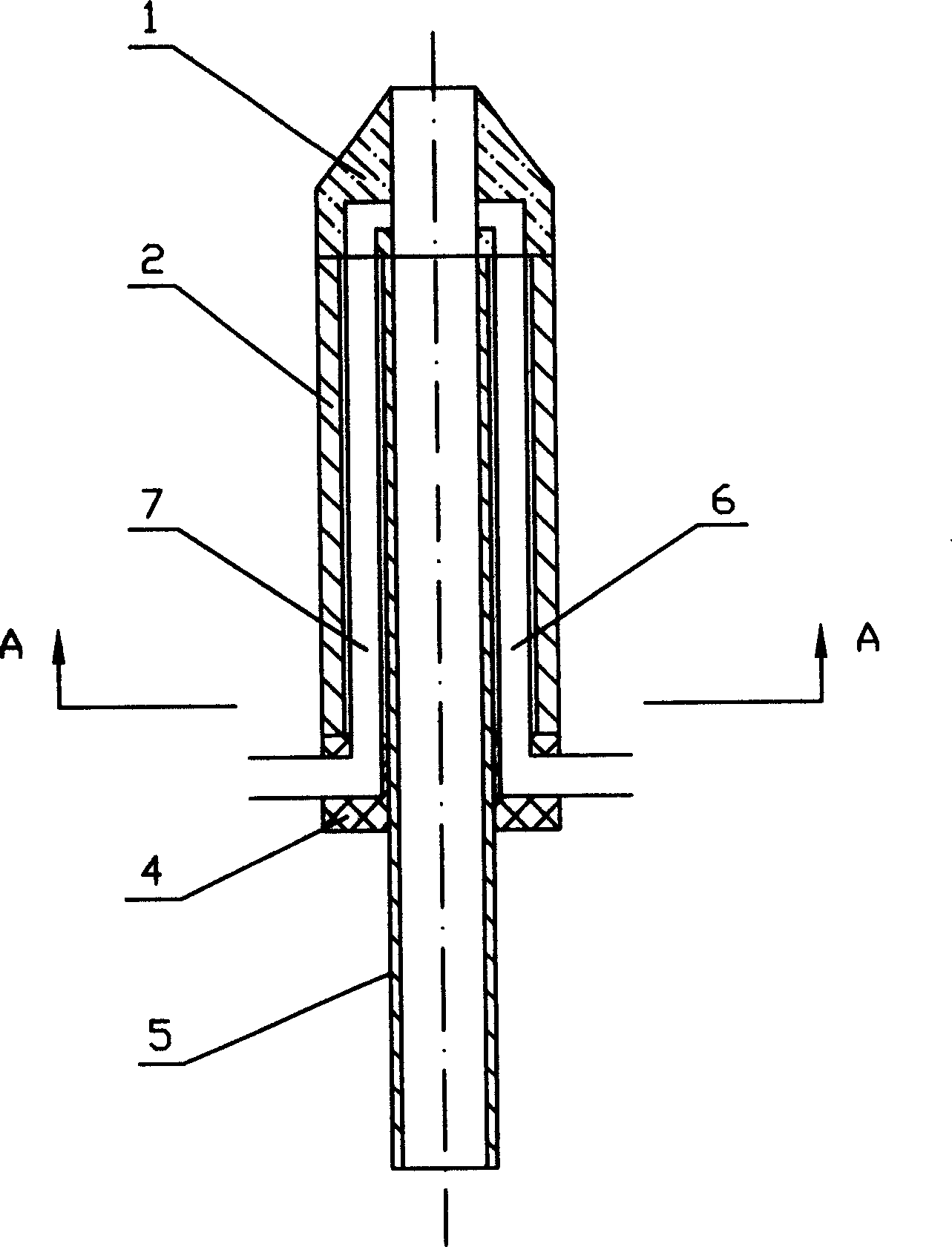

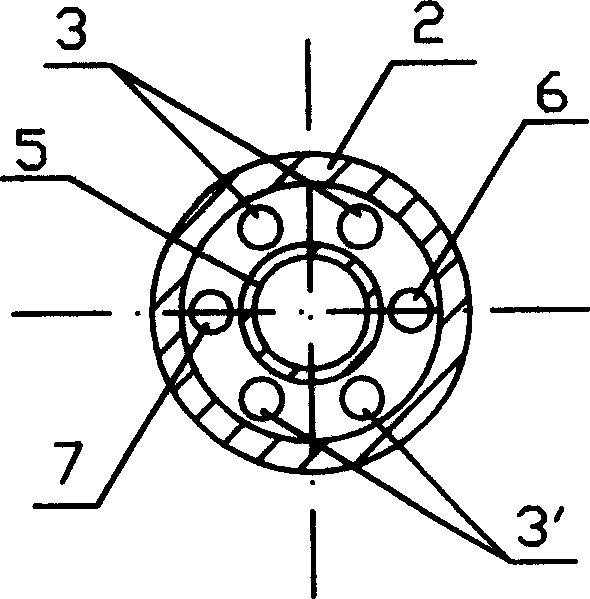

[0010] As shown in the figure, one end of the central sampling pipe 5 is connected to the pipe head 1, and the other end is connected to an air pump to extract high-temperature smoke samples. Other collection and analysis devices. The central sampling tube 5 is covered with an outer casing 2 . Between the central sampling pipe 5 and the outer casing 2, an inlet pipe 3 for cooling water and an outlet pipe 3' for cooling water are provided. The mouth of water inlet pipe 3 is positioned at the lower end of central sampling pipe 5, and the nozzle of outlet pipe 3' is positioned at the upper end of central sampling pipe 5, forming a cooling water circuit to cool the sample taken, so as to realize continuous sampling under high temperature. Two nitrogen pipes 6, 7 are arranged between the central sampling pipe 5 and the outer sleeve pipe 2, and the mouths of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com