Coating and forming method for disk-type parts

A disk-type parts and over-molding technology, applied in the field of titanium alloy and superalloy disk blank manufacturing, can solve the problems of high equipment requirements, performance sacrifice and high cost, and achieve high material utilization, stable performance and good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

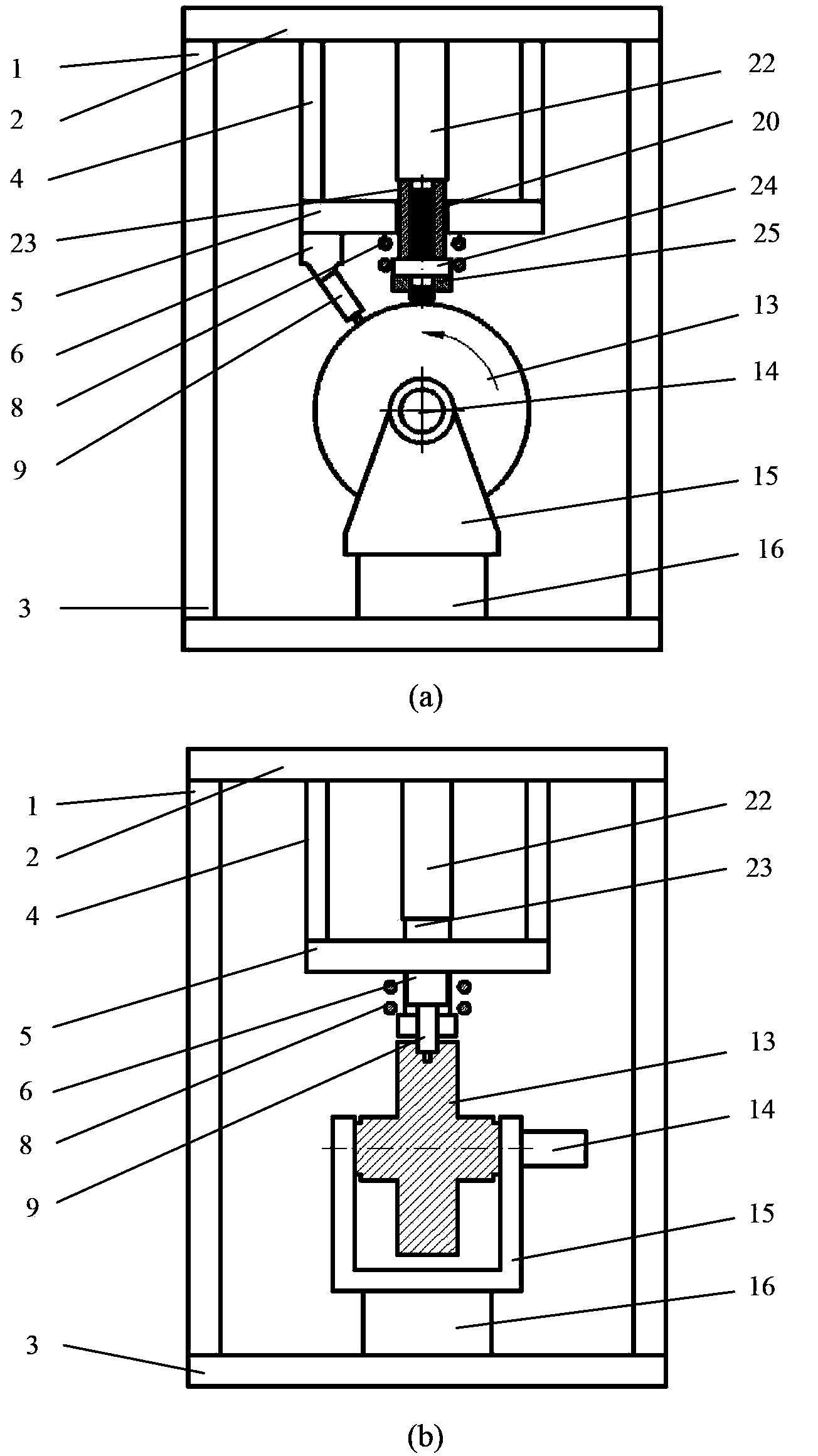

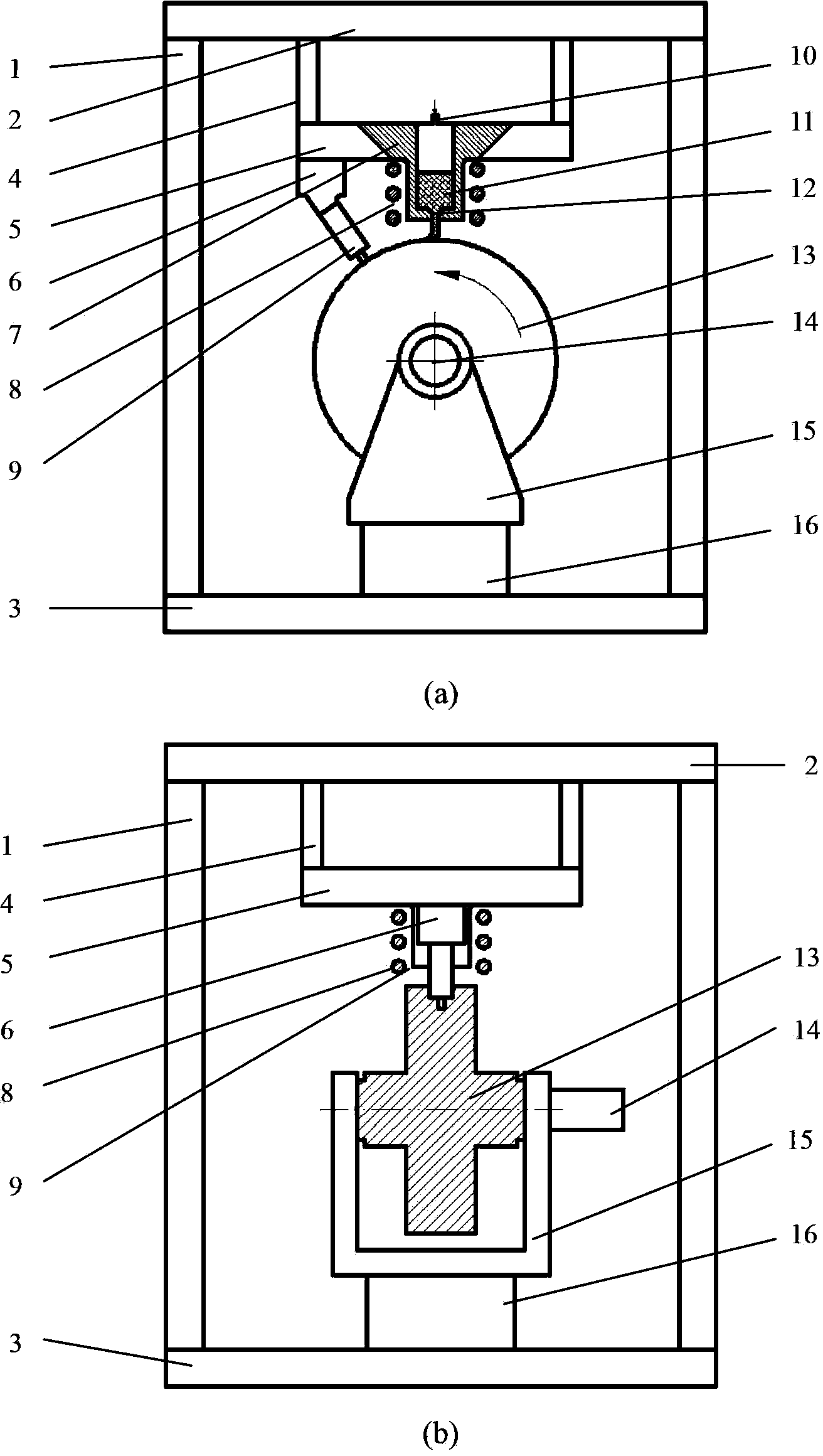

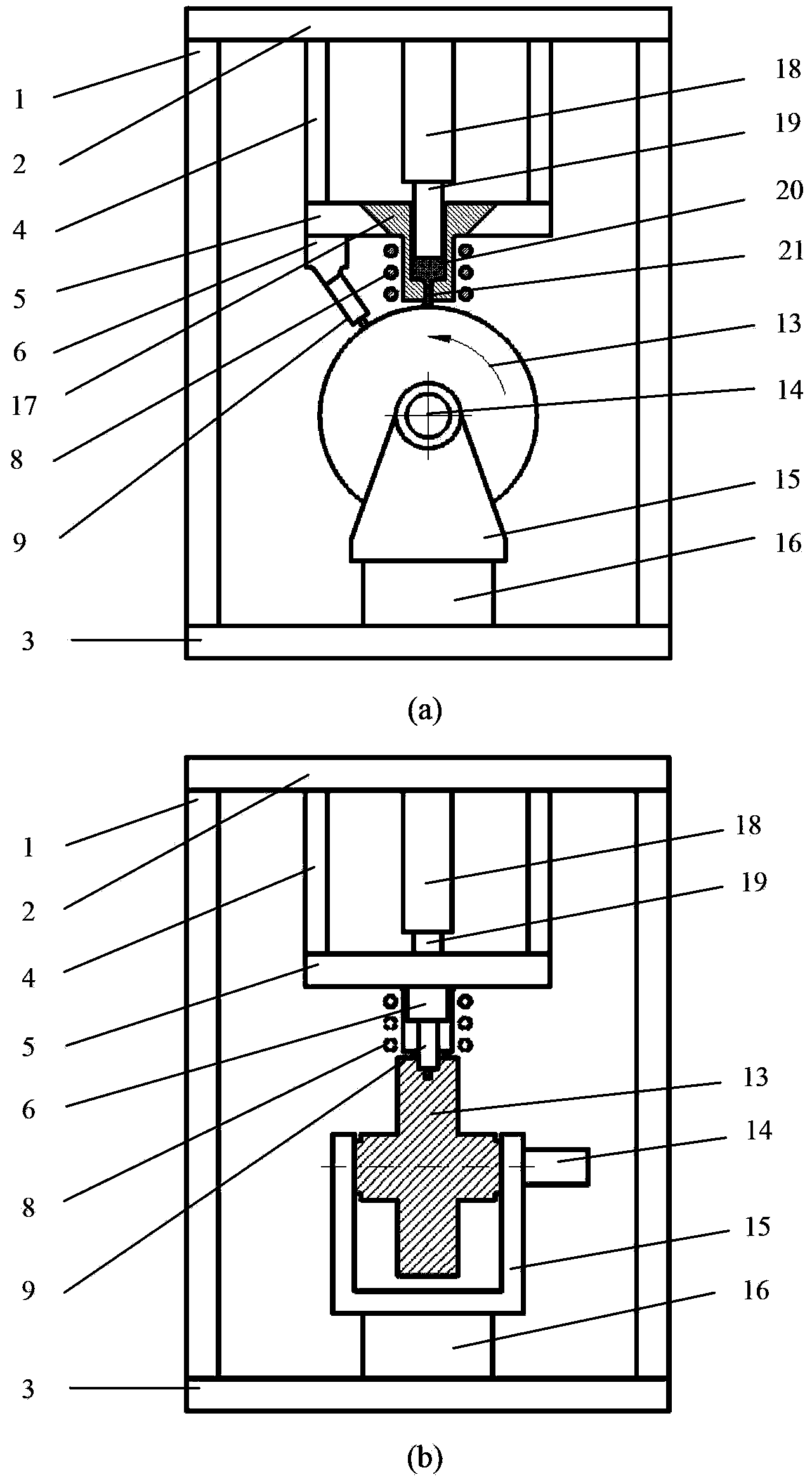

[0061] Embodiment 1: See the structure of the feeding system figure 1

[0062] 1. Add TC4 titanium alloy billet in melting crucible 7, the form of billet can be block material, bar stock etc.,

[0063] 2. Pump the vacuum of the vacuum chamber to 1.0×10 -3 Pa,

[0064] 3. Turn on the induction heating coil 8, melt the TC4 titanium alloy billet, and melt it into a melt 11 at a melting temperature of 1800°C.

[0065] 4. Pass argon gas into the gas nozzle 10, the gas pressure is 2MPa, and the melt is ejected through the melt nozzle 12 by means of air pressure loading. The diameter of the melt nozzle is 5mm, and the melted billet melt 11 Coated on the disk blank rotating shaft 13, the billet just covered is stirred and processed by the stirring head 9, the rotating speed of the stirring head 9 is 800 rpm,

[0066] 5. After the blank rotating shaft 13 rotates one circle, the blank rotating shaft support motion drive system 16 drives the blank rotating shaft support 15 to transla...

Embodiment 2

[0070] 1. Add TC4 titanium alloy billet 20 into extrusion cylinder 17, the billet size is Ф30mm×60mm,

[0071] 2. Pump the vacuum of the vacuum chamber to 1.0×10 -3 Pa,

[0072] 3. Turn on the induction heating coil 8, heat the billet 20, raise the temperature to 920°C, and keep it warm.

[0073] 4. Drive the pusher rod 19 by the pusher rod drive motor 18, and wrap the solid billet 20 on the disc rotating shaft 13 through the extrusion material outlet 21. The diameter of the extrusion barrel outlet is 5mm, and the application of the pusher rod 19 The extrusion load is 1000 kg force, and the billet that has just been covered is stirred and processed by the stirring head 9, and the rotating speed of the stirring head 9 is 800 rpm.

[0074] 5. After the blank rotating shaft 13 rotates one circle, the blank rotating shaft support motion drive system 16 drives the blank rotating shaft support 15 to translate 5mm along the axial direction of the blank rotating shaft 13, and contin...

Embodiment 3

[0078] 1. Add TC4 titanium alloy rod 20 into the barrel 23, wherein the rod size is Ф5mm×5mm,

[0079] 2. Pump the vacuum of the vacuum chamber to 1.0×10 -3 Pa,

[0080] 3. Turn on the induction heating coil 8 to heat the blank 20 at a heating temperature of 500°C.

[0081] 4. Open the switch of the barrel 23, so that a preheated rod-shaped blank 20 enters the blank and rotates the clamping ring 25,

[0082] 5. The top of the rod-shaped blank 20 is clamped by the blank rotating clamping ring 25, the bottom of the clamped rod-shaped blank 20 is in contact with the disc rotating shaft 13, and the cylinder driving system 22 drives the cylinder 23 to rotate and clamp the blank The ring 25 rotates at a speed of 1000 rpm, so that the bottom of the rod-shaped blank 20 and the surface of the disk blank rotating shaft 13 are frictionally heated, and at the same time, the barrel drive system 22 rotates the clamping ring 25 along the barrel 23 and the barrel A downward load is applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com