Etching method, etching system and preparation method of PCB

A PCB board and etching technology, which is applied in the field of PCB board preparation, can solve the problems of poor uniformity of prefabricated lines, etc., and achieve the effect of accelerating etching speed, increasing speed, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

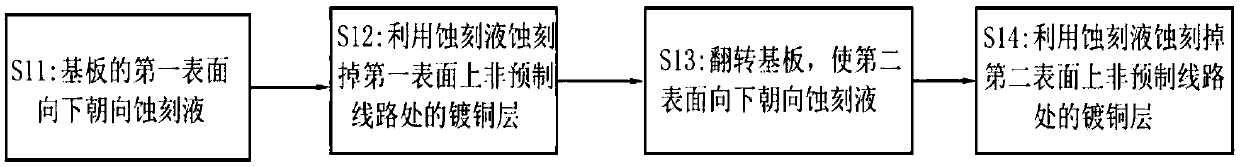

[0069] The present embodiment provides a kind of processing method of circuit side wall of PCB board, as figure 1 shown, including the following steps:

[0070] S11: facing the first surface 11 of the substrate 1 downward toward the etching solution;

[0071] S12: Etching away the copper plating layer at the non-prefabricated circuit on the first surface 11 with an etching solution;

[0072] S13: Flipping the substrate 1 so that the second surface 12 of the substrate 1 opposite to the first surface 11 faces downward toward the etching solution;

[0073] S14: Etching away the copper plating layer on the second surface 12 at the non-prefabricated circuit by using an etching solution.

[0074] The etching method of the above-mentioned PCB board, when etching the copper-plated layer at the non-prefabricated circuit place on the first surface 11 and the second surface 12 of the substrate 1, it is carried out in two times, first to the first surface of the substrate 1 facing downw...

Embodiment 2

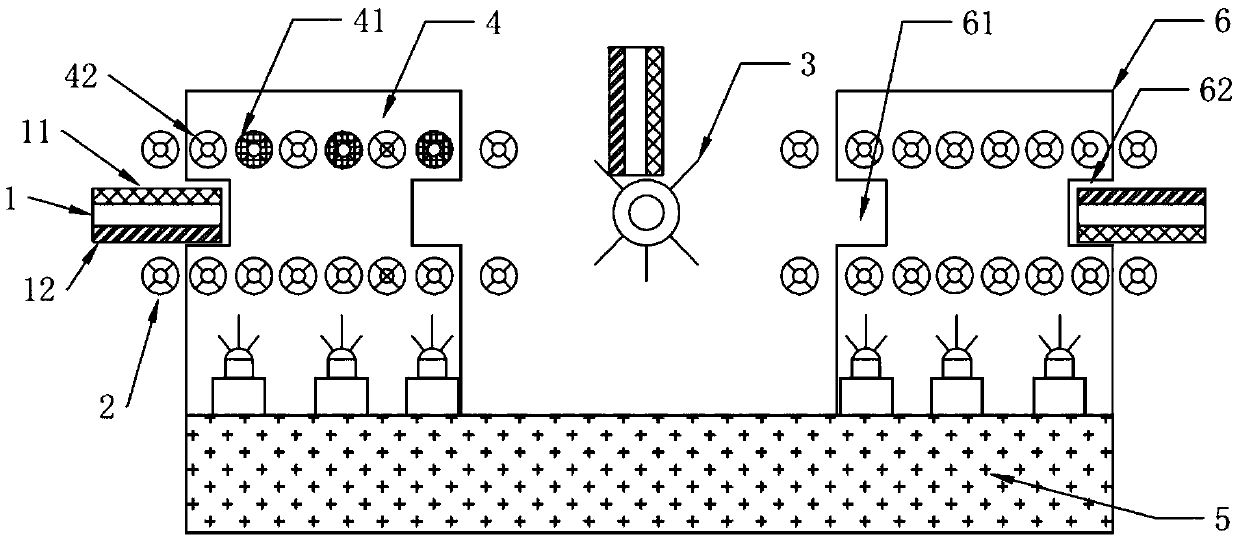

[0083] The present embodiment provides a kind of etching system of PCB board, as figure 2 shown, including

[0084] The conveying device 2 is used to support the substrate 1 and can drive the substrate 1 to move;

[0085] Spraying device, at least one, for spraying etching solution to the surface to be etched of the substrate 1;

[0086] The overturning device 3 is used for overturning the substrate 1 so that the surface to be etched of the substrate 1 faces downward toward the showering device.

[0087] The etching system of the above-mentioned PCB board can only etch the copper plating layer at the non-prefabricated circuit on the downward surface of the substrate 1 at a time. After the etching of the downward surface is completed, the turning device 3 turns the upward surface of the substrate 1 into downward, and then etch the surface; in this way, it can be avoided that when two spraying devices are used to etch the downward surface and the upward surface of the substra...

Embodiment 3

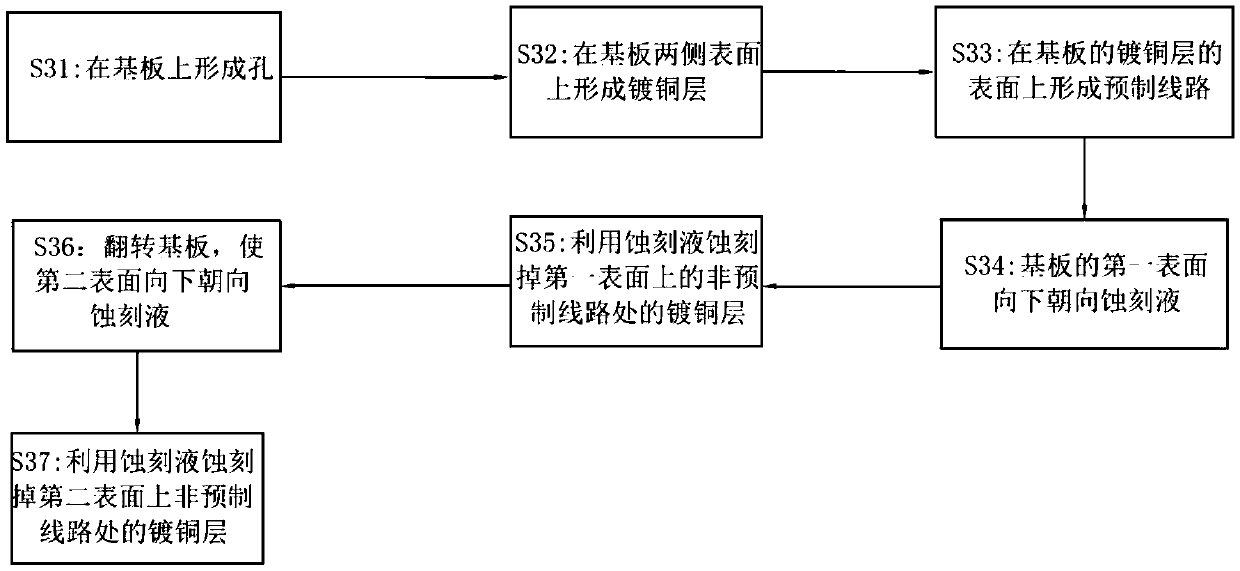

[0100] The present embodiment provides a kind of preparation method of PCB board, as image 3 shown, including the following steps:

[0101] S31: forming a hole on the substrate 1;

[0102] S32: forming a copper plating layer on both sides of the substrate 1;

[0103] S33: forming a prefabricated circuit on the surface of the copper plating layer of the substrate 1;

[0104] S34: directing the first surface 11 of the substrate 1 downward toward the etching solution;

[0105] S35: Etching away the copper plating layer at the non-prefabricated circuit on the first surface 11 with an etching solution;

[0106] S36: Flipping the substrate 1 so that the second surface 12 of the substrate 1 opposite to the first surface 11 faces downward toward the etching solution;

[0107] S37: Etching away the copper plating layer on the second surface 12 at the non-prefabricated circuit by using an etching solution.

[0108] In addition, any other PCB board etching method described in Embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com