Process for preparing perfluorinated sulfonic resin solution by using waste ion exchange membrane in chlor-alkali industry

A perfluorosulfonic acid resin and ion-exchange membrane technology, which is applied in educts, recycling technology, plastic recycling, etc., can solve environmental pollution and other problems, and achieve the effects of wide application range, less impurities, and consistent density performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

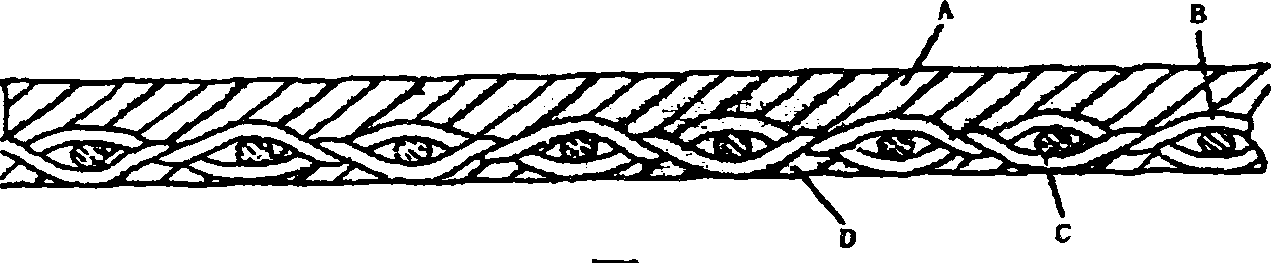

[0042] The waste membrane used in the chlor-alkali industry is composed of four parts: perfluorosulfonic acid ion exchange membrane, perfluorocarboxylic acid ion exchange membrane, PTFE reinforced mesh, and a small amount of inorganic substances. Among them, perfluorosulfonic acid resin is a copolymer formed by copolymerization of tetrafluoroethylene and perfluorovinyl ether, and its ion exchange capacity is 1100g / mol. The surface of the waste ionic membrane is covered with soil, organic impurities and inorganic impurities, etc., and it is dark yellow or reddish brown.

[0043] First of all, it is necessary to repeatedly scrub the waste ionic membrane with a brush to remove most of the inorganic substances attached to the waste membrane. Cut the waste film into 10*10cm 2 small pieces.

[0044] Then, at a temperature of 80°C, a concentration of 1 mol / L H 2 SO 4 Treat for about 1 h in order to remove the inorganic precipitates on the membrane. The membrane was taken out and...

Embodiment 2

[0057] As described in Example 1, a mixed resin of perfluorosulfonic acid and perfluorocarboxylic acid was obtained. Take 15g of mixed resin and put it into a 0.5L autoclave, then add 140ml of isopropanol, 30ml of ethanol and 130ml of deionized water. Will N 2 The tube was connected to the reactor and a thermocouple was inserted into the reactor. Access to N 2 Confirm that the reaction kettle is well sealed, open the gas phase valve, and discharge the gas in the reaction kettle. When the pointer of the pressure gauge shows 0, close the gas phase valve. This process is repeated many times until O 2 content less than 1O -6 until. O contained in the air in the reactor 2 After fully exhausted, pass into N 2 , the pointer shows 3MPa, turn off N 2 valve. Turn on the control power switch to start heating and dissolving.

[0058] Dissolve at 250°C for 5 hours, when the pressure shows 12.1MPa, turn off the power, let the kettle temperature drop slowly at room temperature unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com