SF6 decomposition product multi-component dynamic gas preparation method

A dynamic gas distribution, multi-component technology, used in the analysis of gas mixtures, analytical materials, standard gas analyzers, etc., can solve problems such as electrical performance degradation, equipment accidents, and equipment operation safety hazards, and achieve high control accuracy and distribution. The effect of uniform and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

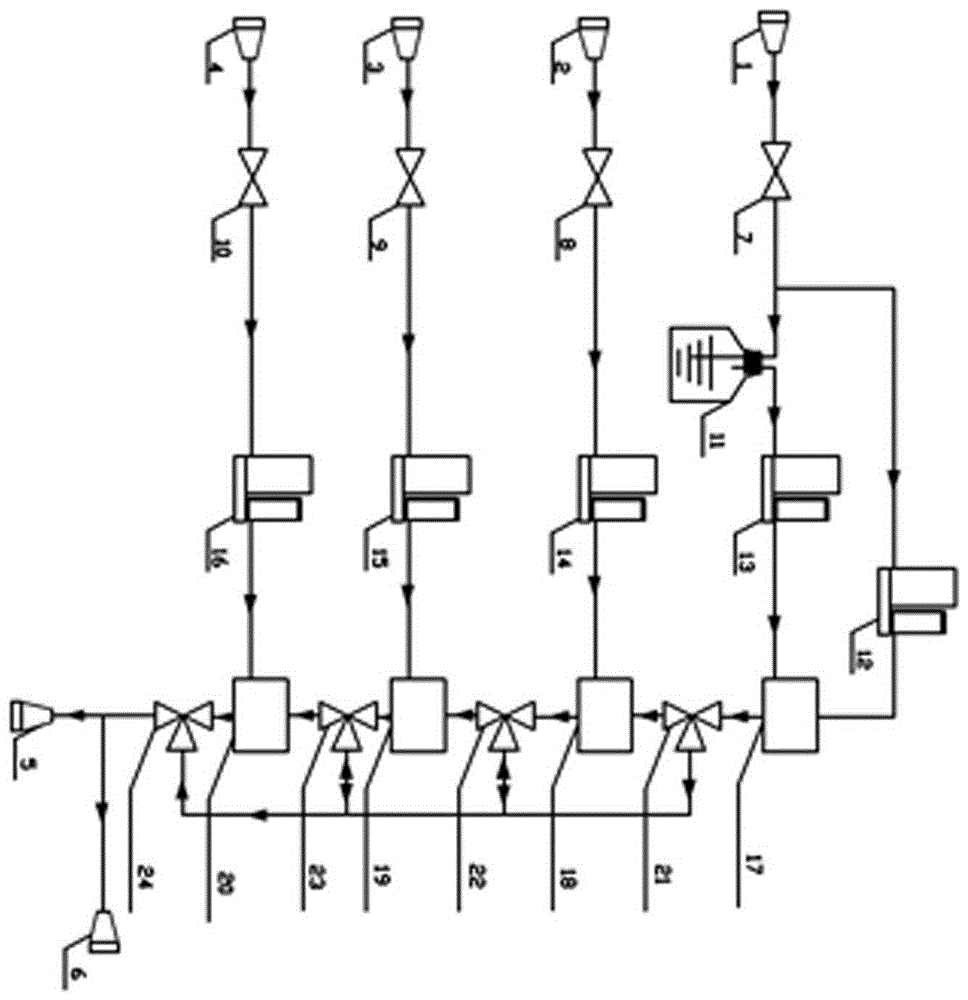

[0029] like figure 1 As shown, the existing SF 6 A bottle of high-purity gas (99.99%), connected to 1 inlet quick-plug connector, standard sample gas 50ppmSO 2 (background gas SF 6 ), 50ppm H 2 S (background gas SF 6 ), 100 ppm CO (background gas SF 6 ) are respectively connected to 2, 3, and 4 of the inlet push-in connectors, and a standard gas with a total flow rate of 512mL needs to be configured. Among them, the dew point temperature Td= -21.8℃ is required, and SO 2 Concentration 5ppm, H 2 The S concentration is 5ppm, and the CO concentration is 10ppm. If the temperature of the water tank is 26.9°C at this time, based on the calculation of the saturated water vapor pressure at this temperature, the wet gas flow rate is 12mL and the dry gas flow rate is 500mL; at the same time, in order to achieve SF 6 Decomposition product multi-component gas distribution concentration, need SO 2 、H 2 Each of the three standard gases of S and CO is 51.2mL, and the three standard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com