Water-fertilizer all-in-one machine

An all-in-one, water and fertilizer technology, which is applied in fertilization devices, liquid fertilizer distribution, and pressurized spreading methods of liquid fertilizers, etc., can solve problems such as inability to increase water impact force, different concentrations of fertilizers before and after concentration, and reduced mixing effect of water and fertilizer mixtures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

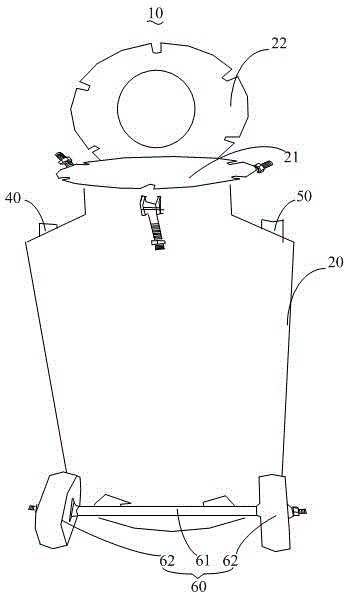

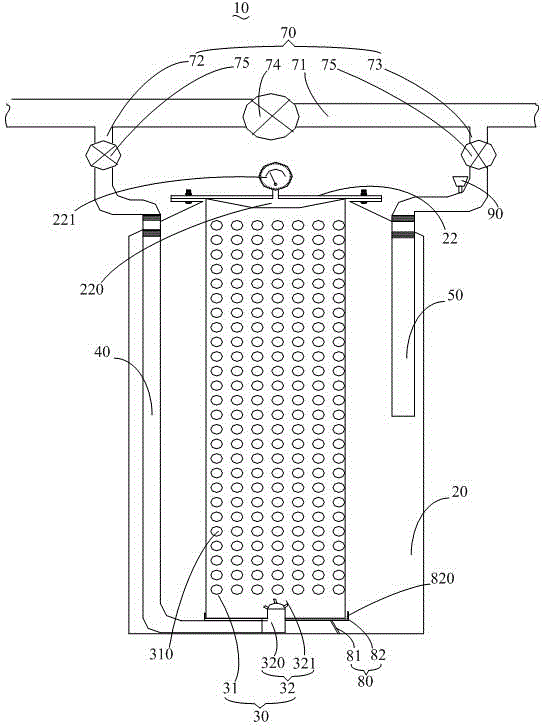

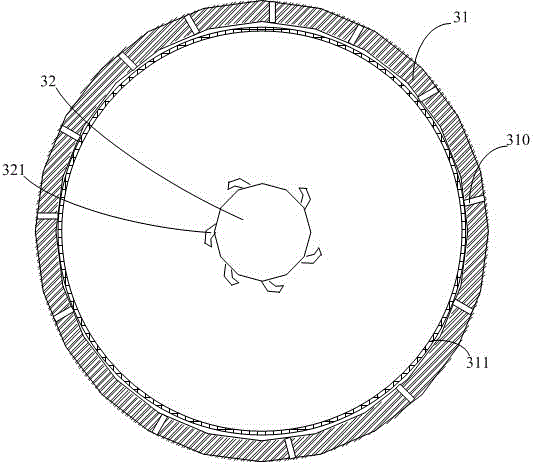

[0013] Please see Figure 1 to Figure 3 The water and fertilizer integrated machine 10 includes a tank body 20, a vortex stirring and filtering device 30, a water inlet pipe 40, and a fertilizer liquid pipeline 50; the vortex stirring and filtering device 30 is fixed in the tank body 20, and one end of the water inlet pipe 40 passes through the tank body 20 Afterwards, it is connected with the vortex stirring and filtering device 30 , and one end of the fertilizer liquid pipeline 50 passes through the tank body 20 and is fixed in the tank body 20 . The vortex stirring filter device 30 comprises a housing portion 31 with a bottom, a water flow directional injection device 32, the accommodation space of the housing portion 31 is cylindrical, and the side wall of the housing portion 31 is provided with a fertilizer liquid discharge hole 310, and the water flow directional injection device 32 is fixed. On the bottom of the receptacle 31, and the water flow inlet end 320 of the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com