Patents

Literature

38results about How to "Offset shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

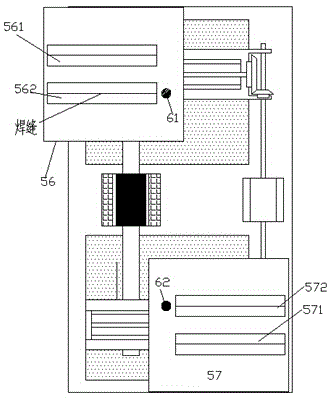

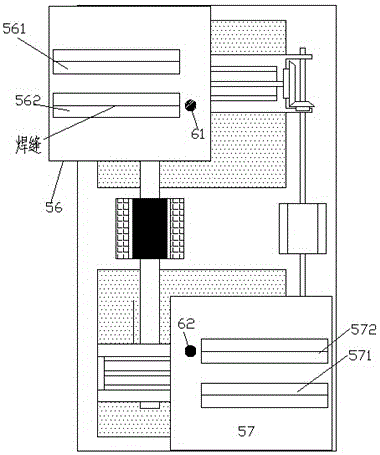

Hydraulic cylinder block weld joint welding device provided with fan for cooling

ActiveCN104439780AOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderClassical mechanics

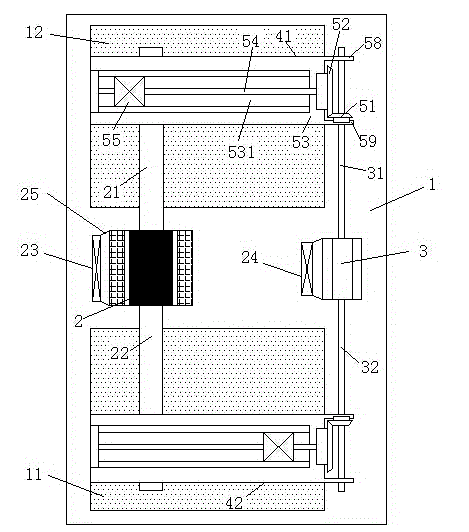

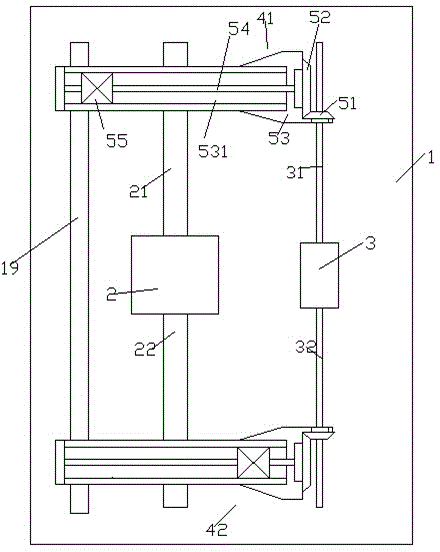

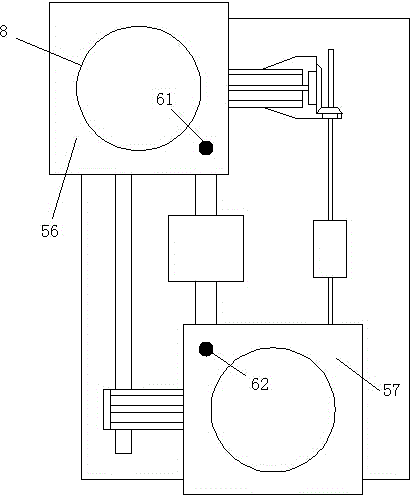

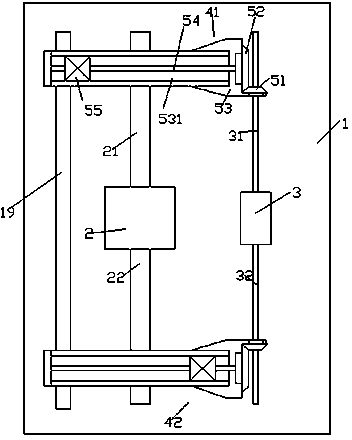

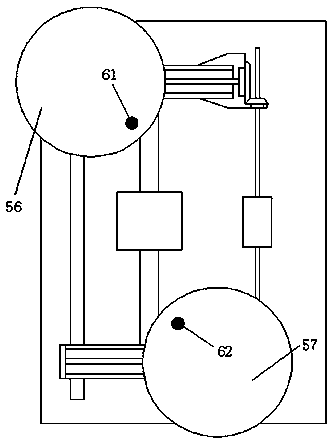

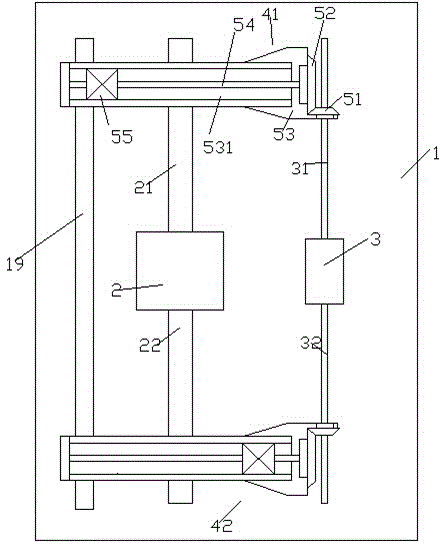

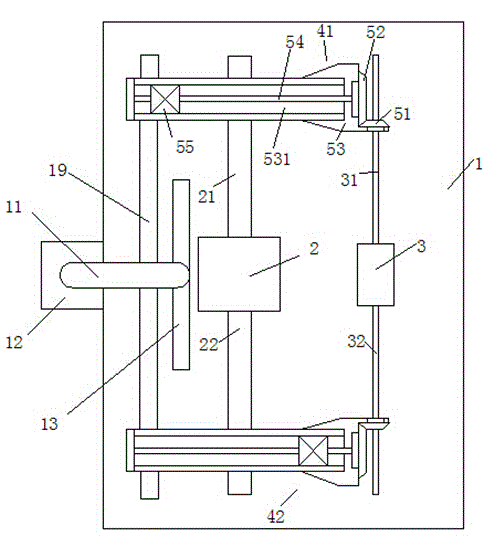

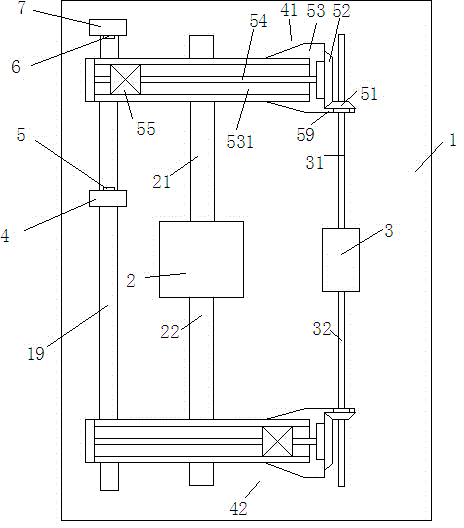

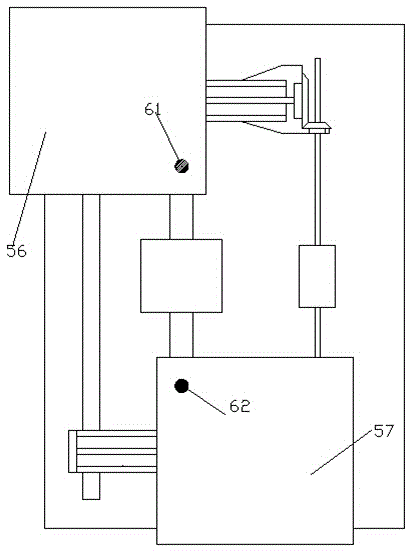

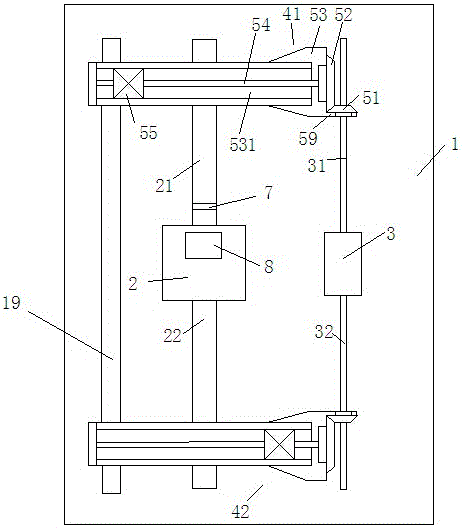

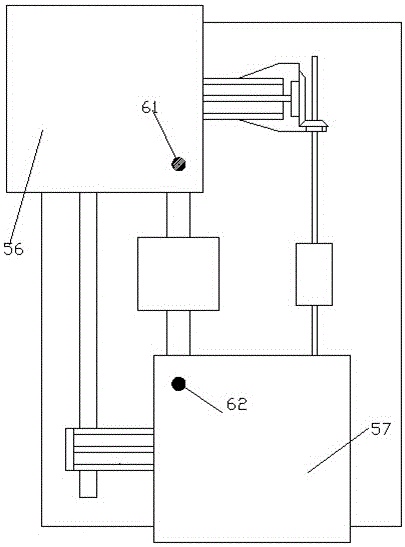

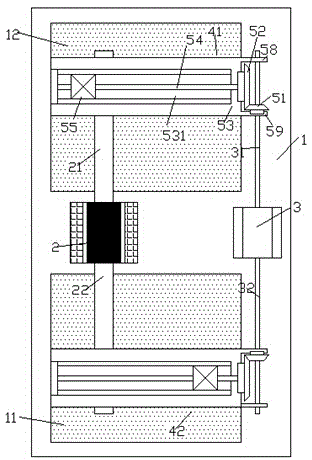

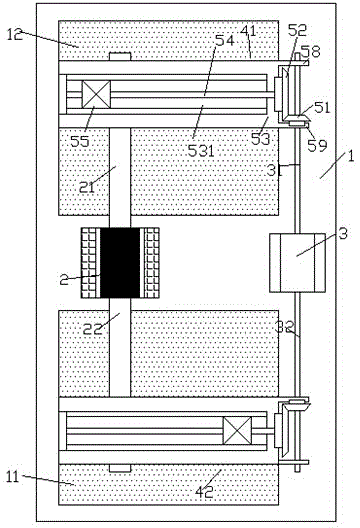

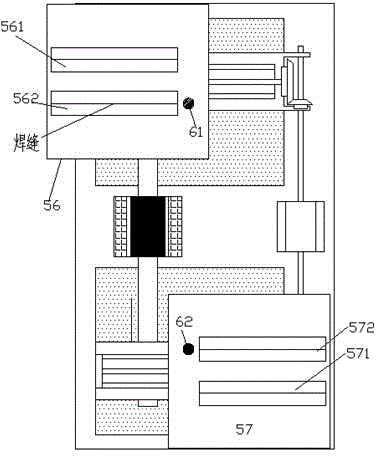

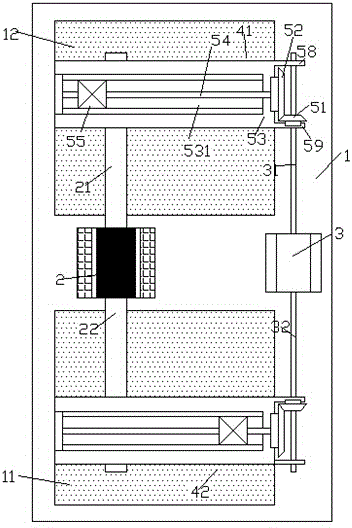

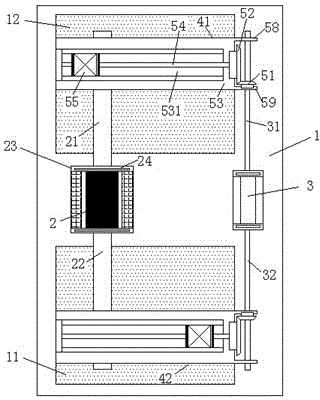

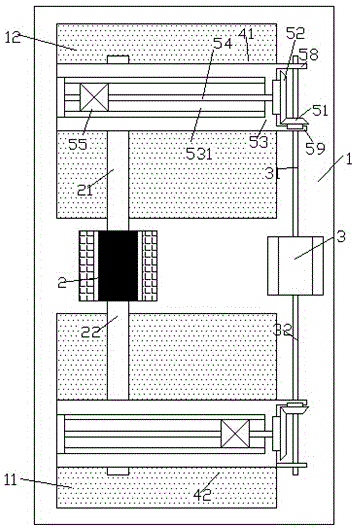

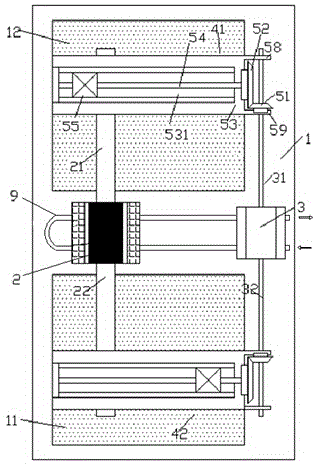

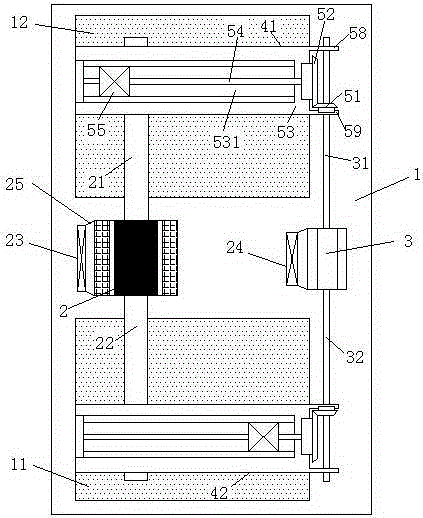

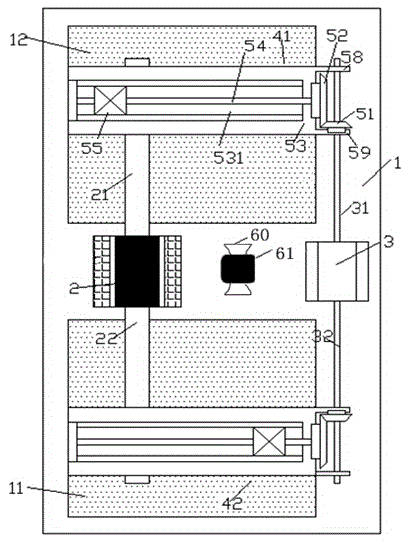

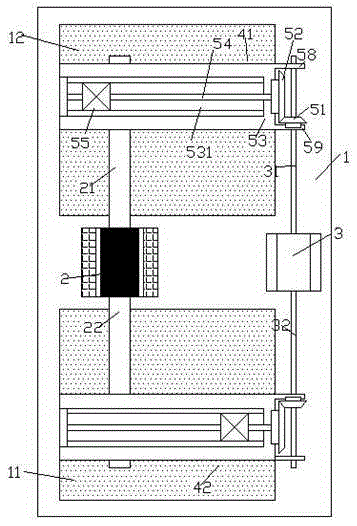

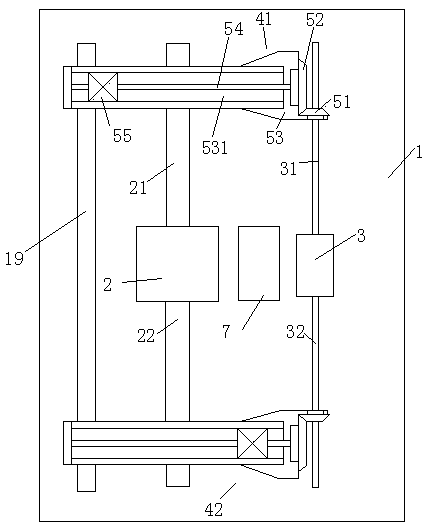

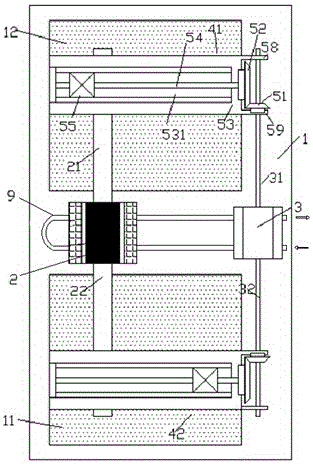

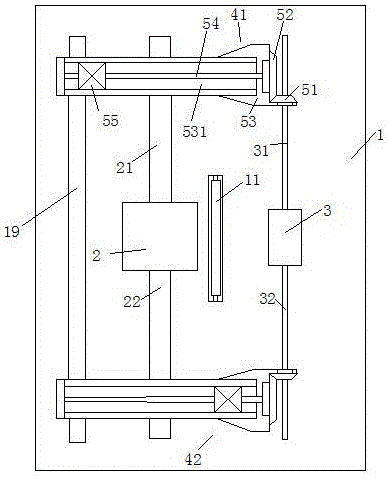

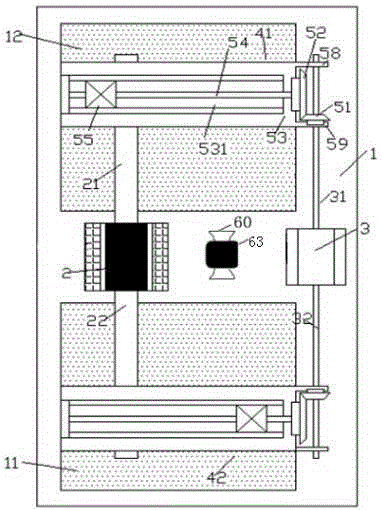

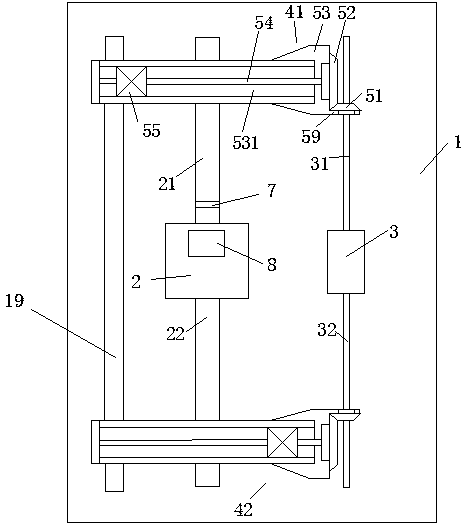

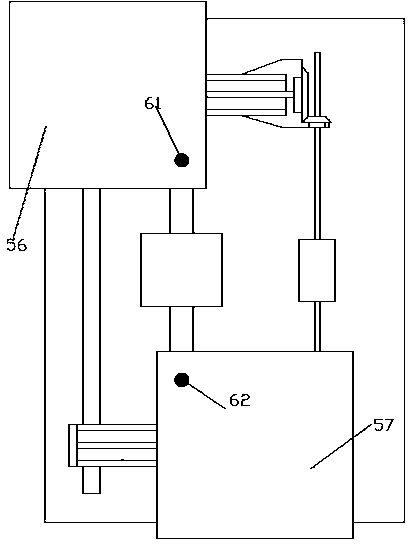

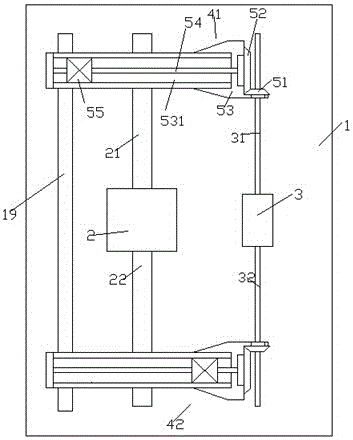

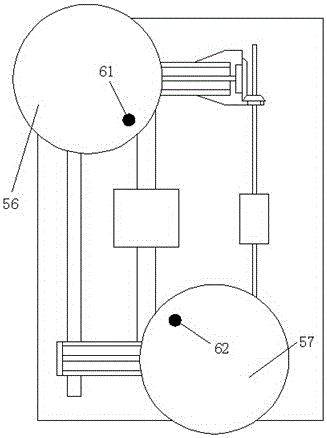

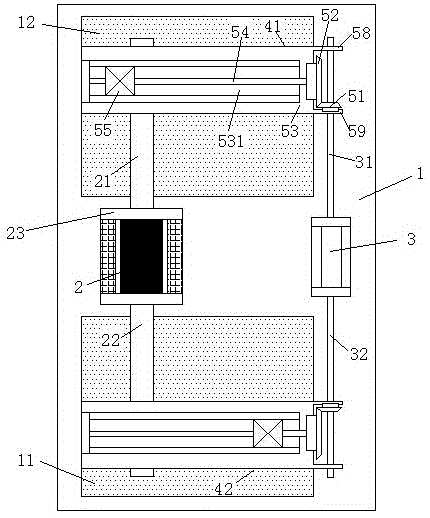

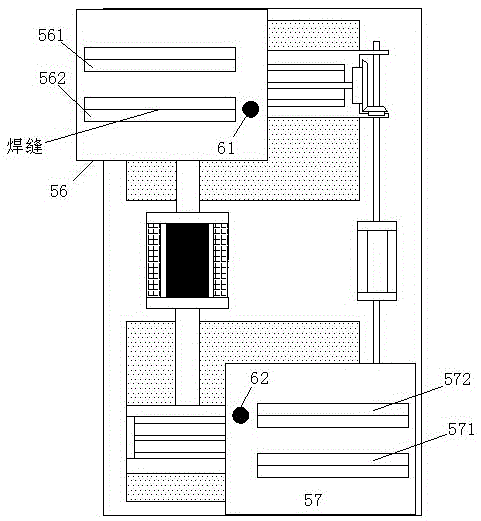

A hydraulic cylinder block weld joint welding device provided with a fan for cooling comprises a machine frame (1), a front sliding base assembly (42), a rear sliding base assembly (41), a sliding base front-back drive motor (2) and a sliding base left-right drive motor (3). The rear sliding base assembly (41) and the front sliding base assembly (42) are arranged in a concave areas (11) and a concave area (12) on the machine frame (1) from back to front in a separated mode and are matched with the corresponding concave areas (11 and 12) in a sliding mode. The sliding base front-back drive motor (2) and the sliding base left-right drive motor (3) are both located between the rear sliding base assembly (41) and the front sliding base assembly (42) and fixedly arranged on the machine frame (1).

Owner:肇庆市高要区洁特不锈钢制品有限公司

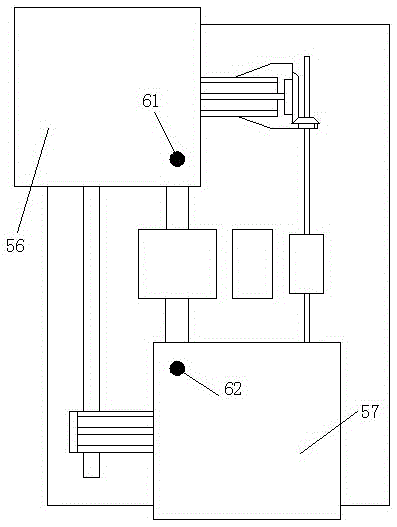

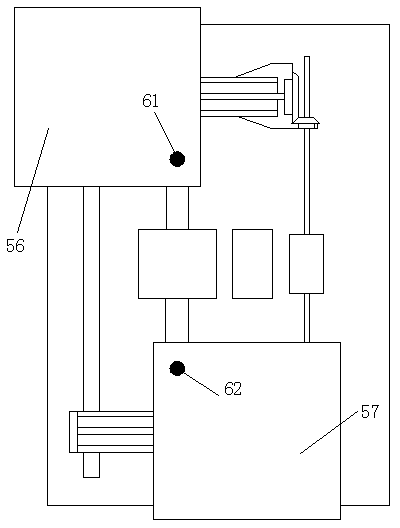

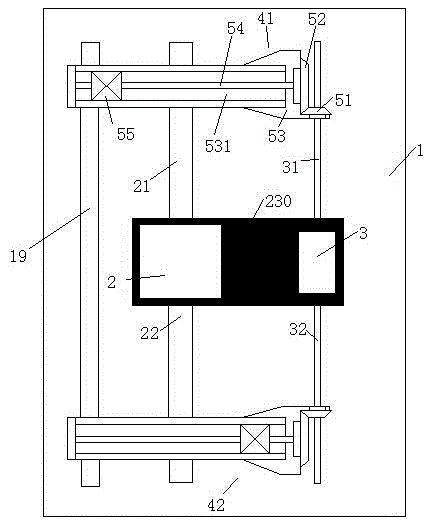

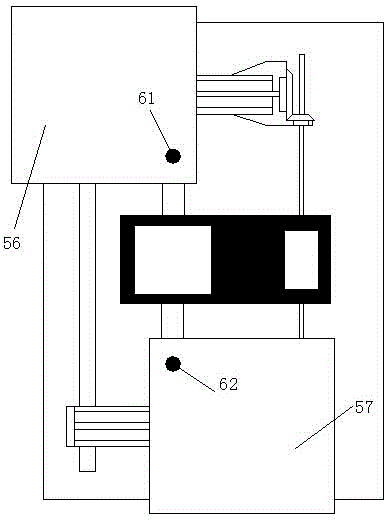

LED dispensing packaging equipment having vacuum chuck

InactiveCN104485413AOffset shockImprove processing efficiencySemiconductor devicesEngineeringDrive motor

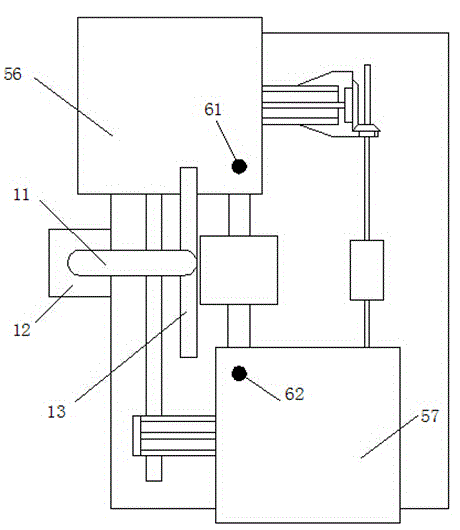

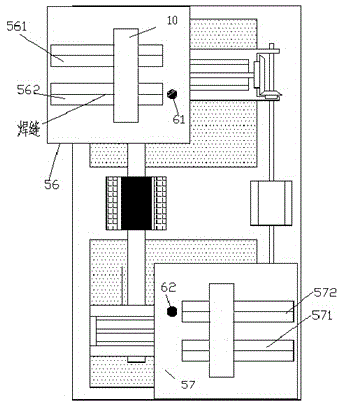

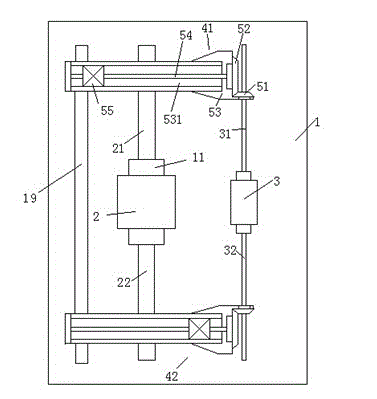

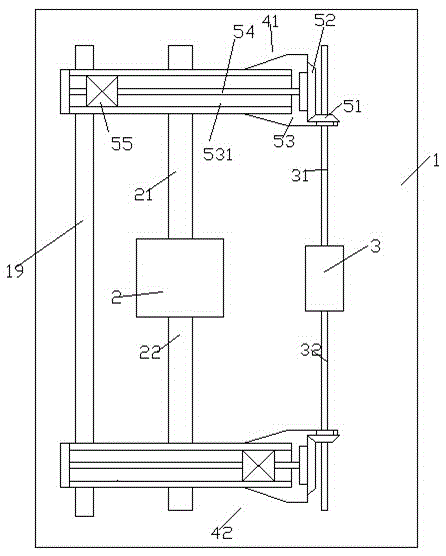

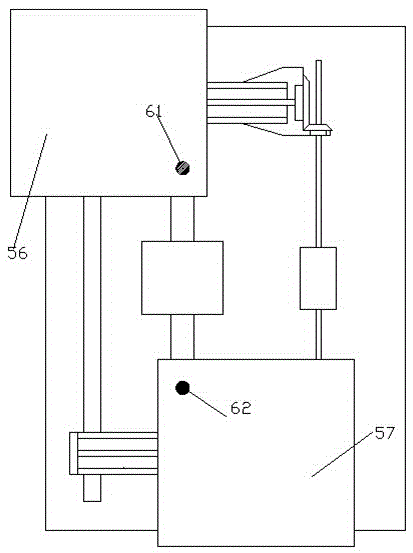

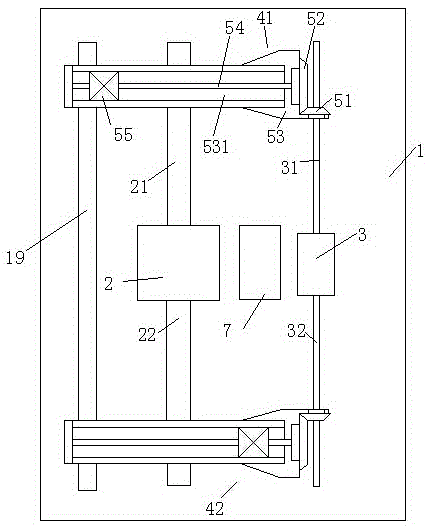

The invention relates to an LED dispensing packaging equipment having a vacuum chuck. The LED dispensing packaging equipment comprises a frame (1), a front sliding seat assembly (42), a back sliding seat assembly (41), a vertical driving motor (2) and a transverse driving motor (3), wherein the frame (1) is vertically arranged on a frame guide rail (19), the back sliding seat assembly (41) and the front sliding seat assembly (42) are arranged on the frame (1) separately back and forth and are in sliding matching with the frame guide rail (19), and the vertical driving motor (2) and the transverse driving motor (3) are between the back sliding seat assembly (41) and the front sliding seat assembly (42) and are fixedly arranged on the frame (1).

Owner:洪恒丰

LED adhesive-dispensing package device with round rotating tray

ActiveCN104319339AOffset shockImpact forceLiquid surface applicatorsCoatingsAdhesiveElectric machinery

An LED adhesive-dispensing package device with a round rotating tray comprises a rack (1), a front slide seat module (42), a rear slide seat module (41), a longitudinal drive motor (2) and a transverse drive motor (3), wherein a rack guide rail (19) is longitudinally arranged on the rack (1), and the rear slide seat module (41) and the front slide seat module (42) are arranged on the rack (1) in a front-rear separated mode and are in sliding fit with the rack guide rail (19). The longitudinal drive motor (2) and the transverse drive motor (3) are arranged between the rear slide seat module (41) and the front slide seat module (42) and are fixedly arranged on the rack (1).

Owner:常熟东南高新技术创业服务有限公司

LED dispensing packaging device

InactiveCN104465943AOffset shockImprove processing efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesDrive motor

The invention provides an LED dispensing packaging device. The LED dispensing packaging device comprises a rack (1), a front sliding seat assembly (42), a rear sliding seat assembly (41), a longitudinal drive motor (2) and a transverse drive motor (3). A rack guide rail (19) is longitudinally arranged on the rack (1), and the rear sliding seat assembly (41) and the front sliding seat assembly (42) are arranged on the rack (1) in a forward and backward separation mode and in sliding fit with the rack guide rail (19). The longitudinal drive motor (2) and the transverse drive motor (3) are both arranged between the rear sliding seat assembly (41) and the front sliding seat assembly (42) and fixedly arranged on the rack (1).

Owner:国网山东省电力公司临清市供电公司 +1

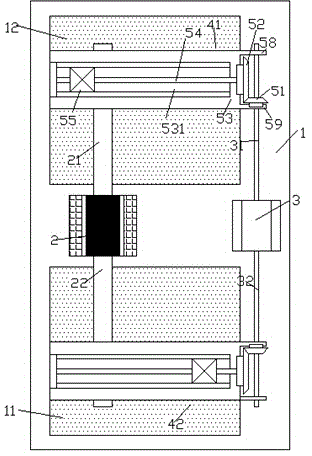

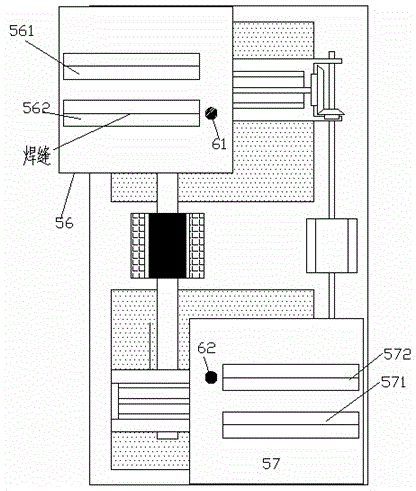

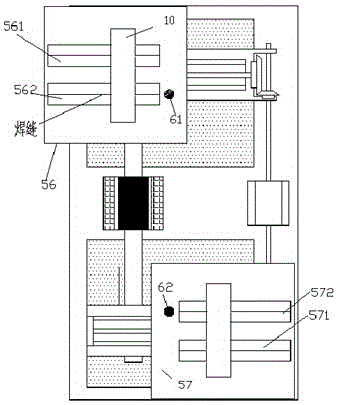

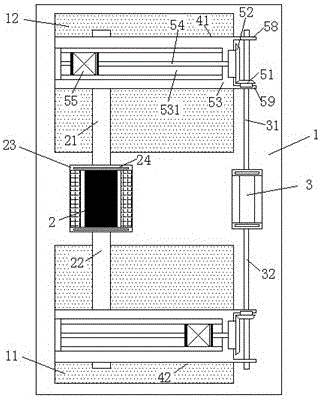

Seam welding device for hydraulic cylinder body

InactiveCN104475996AOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

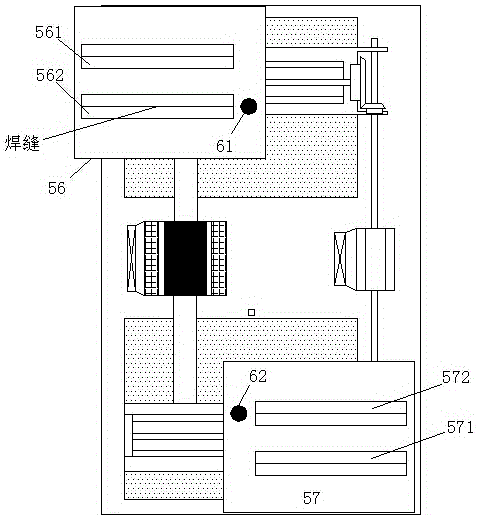

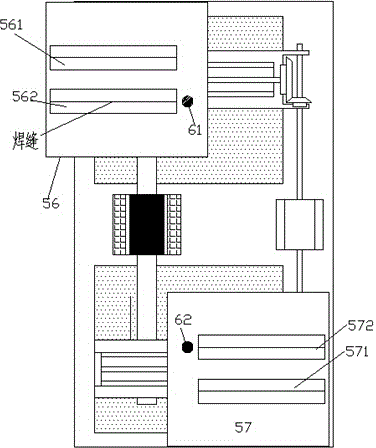

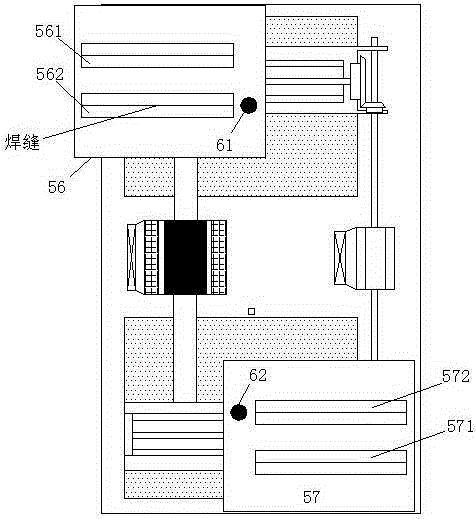

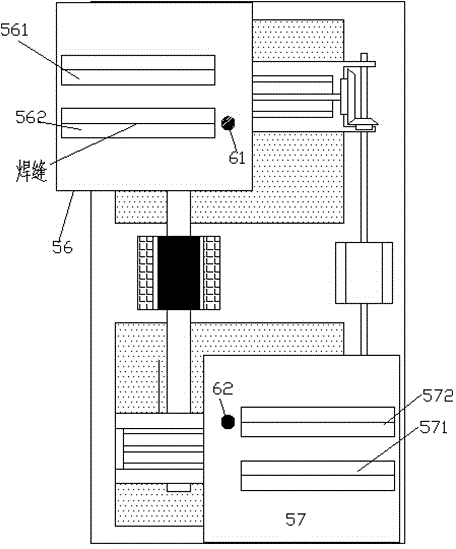

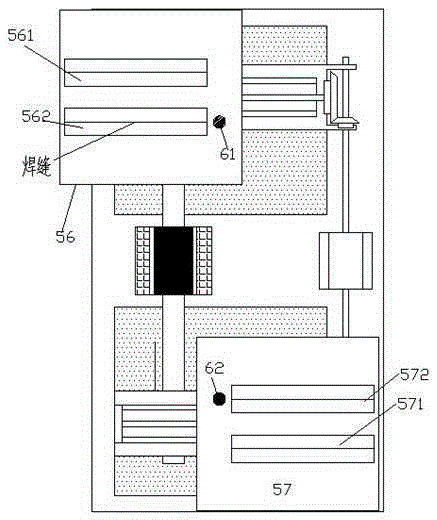

The invention provides a seam welding device for a hydraulic cylinder body. The seam welding device for the hydraulic cylinder body comprises a rack (1), a front sliding seat assembly (42), a rear sliding seat assembly (41), a front and rear driving motor (2) for a sliding seat, and a left and right driving motor (3) for the sliding seat; the rear sliding seat assembly (41) and the front sliding seat assembly (42) are arranged into two separated concave areas (11, 12) in the rack (1) by a manner that one is at the front and another one is at the back, and the rear sliding seat assembly (41) and the front sliding seat assembly (42) are in sliding fitting with the corresponding concave areas (11, 12); the front and rear driving motor (2) for the sliding seat and the left and right driving motor (3) for the sliding seat are both fixedly arranged between the rear sliding seat assembly (41) and the front sliding seat assembly (42) and on the rack (1).

Owner:酒泉新能钢构有限公司

LED adhesive dispensing packaging device with dust removal function

An LED adhesive dispensing packaging device with the dust removal function comprises a rack (1), a front slide base assembly (42), a rear slide base assembly (41), a longitudinal driving motor (2) and a transverse driving motor (3), wherein a rack guide rail (19) is longitudinally arranged on the rack (1), the rear slide base assembly (41) and the front slide base assembly (42) are arranged on the rack (1) in a front and back separated mode and are in sliding fit with the rack guide rail (19), and the longitudinal driving motor (2) and the transverse driving motor (3) are arranged between the rear slide base assembly (41) and the front slide base assembly (42) and fixedly arranged on the rack (1).

Owner:王莉英

LED dispensing packaging equipment having front and back limit sensors

InactiveCN104409610AOffset shockImprove processing efficiencySemiconductor devicesEngineeringDrive motor

The invention relates to an LED dispensing packaging equipment having front and back limit sensors. The LED dispensing packaging equipment having the front and back limit sensors comprises a frame (1), a front sliding seat assembly (42), a back sliding seat assembly (41), a vertical driving motor (2) and a transverse driving motor (3), wherein the frame (1) is vertically provided with a frame guide rail (19), the front sliding seat assembly (42) and the back sliding seat assembly (41) are separately arranged on the frame (1) forth and back and are in sliding matching with the frame guide rail (19), and the vertical driving motor (2) and the transverse driving motor (3) are respectively arranged between the back sliding seat assembly (41) and the front sliding seat assembly (42) and are fixedly arranged on the frame (1).

Owner:钱红霞

A led dispensing encapsulation equipment with position sensor and alarm

ActiveCN104384068BOffset shockImprove processing efficiencyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses an LED dispensing and packaging device with a position sensor and an alarm. The LED dispensing and packaging device comprises a rack (1), a front slide seat component (42), a rear slide seat component (41), a longitudinal driving motor (2) and a horizontal driving motor (3), wherein the rack (1) is longitudinally provided with a rack guide rail (19); the rear slide seat component (41) and the front slide seat component (42) are arranged on the rack (1) in a front-and-back separating mode and are matched with the rack guide rail (19) in a matched mode; the longitudinal driving motor (2) and the horizontal driving motor (3) are both positioned between the rear slide seat component (41) and the front slide seat component (42) and are fixedly arranged on the rack (1).

Owner:南通睿博电器有限公司

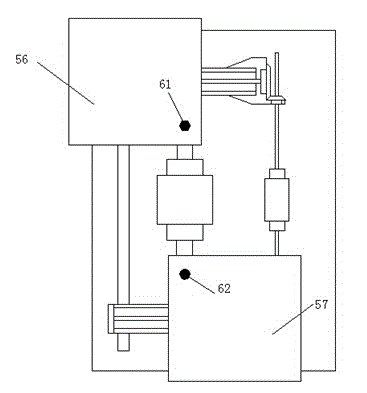

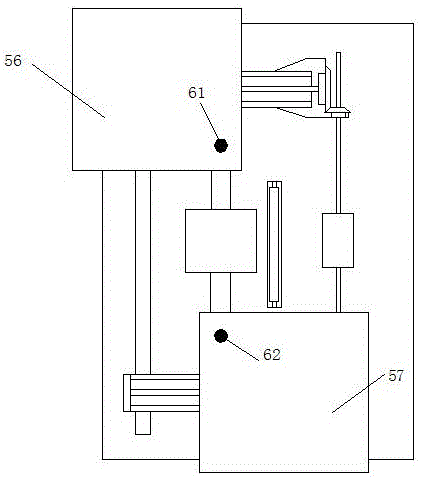

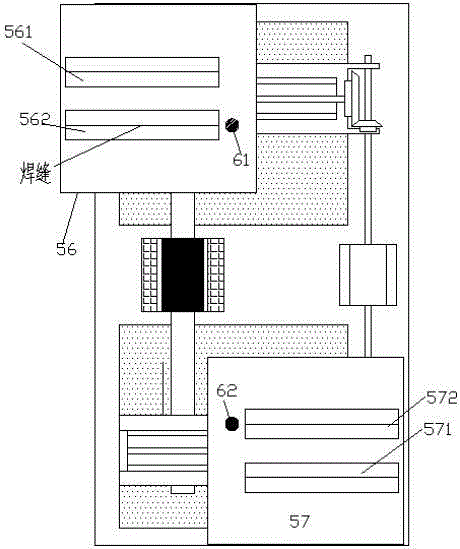

Control system for seam welding of hydraulic cylinder body

ActiveCN104476024AOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderControl system

The invention provides a control system for seam welding of a hydraulic cylinder body. The control system for the seam welding of the hydraulic cylinder body comprises a controller, a motor driving circuit and a welding device; the welding device comprises a rack, a front sliding seat assembly, a rear sliding seat assembly, a front and rear driving motor for a sliding seat, and a left and right driving motor for the sliding seat; the motor driving circuit is respectively connected with the front and rear driving motor for the sliding seat and the left and right driving motor for the sliding seat, wherein the front and rear driving motor for the sliding seat and the left and right driving motor for the sliding seat are arranged in the welding device; the controller controls the front and rear driving motor for the sliding seat and the left and right driving motor for the sliding seat to rotate through the motor driving circuit; the front sliding seat assembly and the front sliding seat assembly are separately arranged in the front and back into two separated concave areas in the rack and are in sliding fitting with the corresponding concave areas; the front and rear driving motor for the sliding seat and the left and right driving motor for the sliding seat are fixedly arranged on the rack, between the rear sliding seat assembly and the front sliding seat assembly.

Owner:JIANGSU DUKE NEW ENERGY AUTOMOBILE

Operation method of welding device for welding joint of hydraulic cylinder body

InactiveCN104439873AOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

An operation method of a welding device for a welding joint of a hydraulic cylinder body is characterized in that the welding device comprises a machine frame (1), a front sliding base assembly (42), a rear sliding base assembly (41), a sliding base front and back driving electric motor (2) and a sliding base left and right driving electric motor (3), and the rear sliding base assembly (41) and the front sliding base assembly (42) are separately arranged in two separated concave areas (11 and 12) on the machine frame (1) in the front and back mode and in sliding fit with the concave areas (11 and 12); the sliding base front and back driving electric motor (2) and the sliding base left and right driving electric motor (3) are fixedly arranged between the rear sliding base assembly (41) and the front sliding base assembly (42) and fixedly arranged on the machine frame (1).

Owner:南通欧特建材设备有限公司

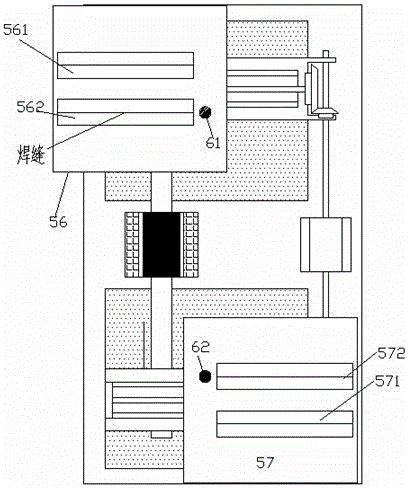

Hydraulic cylinder block weld joint welding device with air blowing device

ActiveCN104439779AOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderDrive motor

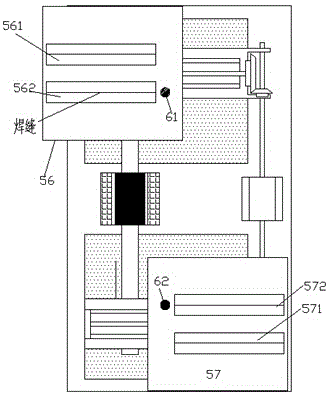

The invention provides a hydraulic cylinder block weld joint welding device with an air blowing device. The hydraulic cylinder block weld joint welding device with the air blowing device comprises a machine frame (1), a front sliding base assembly (42), a rear sliding base assembly (41), a sliding base front-back drive motor (2) and a sliding base left-right drive motor (3). The rear sliding base assembly (41) and the front sliding base assembly (42) are arranged in two separated concave areas (11 and 12) on the machine frame (1) from back to front in a separated mode and are matched with the corresponding concave areas (11 and 12) in a sliding mode. The sliding base front-back drive motor (2) and the sliding base left-right drive motor (3) are both located between the rear sliding base assembly (41) and the front sliding base assembly (42) and fixedly arranged on the machine frame (1).

Owner:南通艺普机械制造有限公司

Hydraulic cylinder block weld joint welding device with self-lubricating function

InactiveCN104439782AOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderClassical mechanics

A hydraulic cylinder block weld joint welding device with the self-lubricating function comprises a machine frame (1), a front sliding base assembly (42), a rear sliding base assembly (41), a sliding base front-back drive motor (2) and a sliding base left-right drive motor (3). The rear sliding base assembly (41) and the front sliding base assembly (42) are arranged in two separated concave areas (11 and 12) on the machine frame (1) from back to front in a separated mode and are matched with the corresponding concave areas (11 and 12) in a sliding mode. The sliding base front-back drive motor (2) and the sliding base left-right drive motor (3) are both located between the rear sliding base assembly (41) and the front sliding base assembly (42) and fixedly arranged on the machine frame (1).

Owner:王仲杰

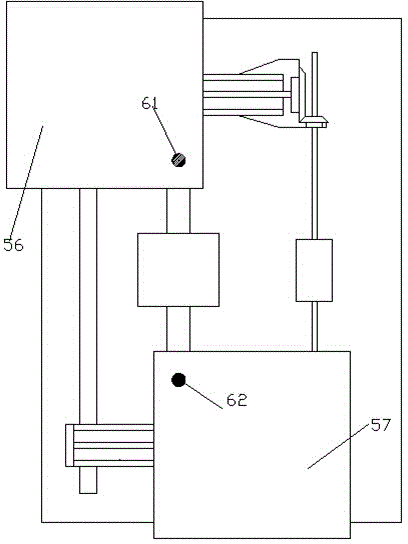

A hydraulic cylinder body welding seam welding device with an air blowing device

ActiveCN104439779BOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

The invention provides a hydraulic cylinder block weld joint welding device with an air blowing device. The hydraulic cylinder block weld joint welding device with the air blowing device comprises a machine frame (1), a front sliding base assembly (42), a rear sliding base assembly (41), a sliding base front-back drive motor (2) and a sliding base left-right drive motor (3). The rear sliding base assembly (41) and the front sliding base assembly (42) are arranged in two separated concave areas (11 and 12) on the machine frame (1) from back to front in a separated mode and are matched with the corresponding concave areas (11 and 12) in a sliding mode. The sliding base front-back drive motor (2) and the sliding base left-right drive motor (3) are both located between the rear sliding base assembly (41) and the front sliding base assembly (42) and fixedly arranged on the machine frame (1).

Owner:南通艺普机械制造有限公司

Hydraulic cylinder block weld joint welding device with cooling water pipe

ActiveCN104439859AOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderDrive motor

A hydraulic cylinder block weld joint welding device with a cooling water pipe comprises a machine frame (1), a front sliding base assembly (42), a rear sliding base assembly (41), a sliding base front-back drive motor (2) and a sliding base left-right drive motor (3). The rear sliding base assembly (41) and the front sliding base assembly (42) are arranged in two separated concave areas (11 and 12) on the machine frame (1) from back to front in a separated mode and are matched with the corresponding concave areas (11 and 12) in a sliding mode. The sliding base front-back drive motor (2) and the sliding base left-right drive motor (3) are both located between the rear sliding base assembly (41) and the front sliding base assembly (42) and fixedly arranged on the machine frame (1).

Owner:福建省鑫建锋机械制造有限公司

A hydraulic cylinder block welding seam welding device with fan cooling

ActiveCN104439780BOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

A hydraulic cylinder block weld joint welding device provided with a fan for cooling comprises a machine frame (1), a front sliding base assembly (42), a rear sliding base assembly (41), a sliding base front-back drive motor (2) and a sliding base left-right drive motor (3). The rear sliding base assembly (41) and the front sliding base assembly (42) are arranged in a concave areas (11) and a concave area (12) on the machine frame (1) from back to front in a separated mode and are matched with the corresponding concave areas (11 and 12) in a sliding mode. The sliding base front-back drive motor (2) and the sliding base left-right drive motor (3) are both located between the rear sliding base assembly (41) and the front sliding base assembly (42) and fixedly arranged on the machine frame (1).

Owner:肇庆市高要区洁特不锈钢制品有限公司

Variable-speed LED adhesive dispensing packaging device

InactiveCN104465967AOffset shockImpact forceSemiconductor/solid-state device manufacturingSemiconductor devicesElectric machineryDrive motor

A variable-speed LED adhesive dispensing packaging device comprises a rack (1), a front slide base assembly (42), a rear slide base assembly (41), a longitudinal driving motor (2) and a transverse driving motor (3), wherein a rack guide rail (19) is longitudinally arranged on the rack (1), the rear slide base assembly (41) and the front slide base assembly (42) are arranged on the rack (1) in a front and back separated mode and are in sliding fit with the rack guide rail (19), and the longitudinal driving motor (2) and the transverse driving motor (3) are arranged between the rear slide base assembly (41) and the front slide base assembly (42) and fixedly arranged on the rack (1).

Owner:李良学

A hydraulic cylinder body welding seam welding device with self-lubricating function

InactiveCN104439782BOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderDrive motor

A hydraulic cylinder block weld joint welding device with the self-lubricating function comprises a machine frame (1), a front sliding base assembly (42), a rear sliding base assembly (41), a sliding base front-back drive motor (2) and a sliding base left-right drive motor (3). The rear sliding base assembly (41) and the front sliding base assembly (42) are arranged in two separated concave areas (11 and 12) on the machine frame (1) from back to front in a separated mode and are matched with the corresponding concave areas (11 and 12) in a sliding mode. The sliding base front-back drive motor (2) and the sliding base left-right drive motor (3) are both located between the rear sliding base assembly (41) and the front sliding base assembly (42) and fixedly arranged on the machine frame (1).

Owner:王仲杰

Hydraulic cylinder block weld joint welding device with lighting device

InactiveCN104439781AOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

A hydraulic cylinder block weld joint welding device with a lighting device comprises a machine frame (1), a front sliding base assembly (42), a rear sliding base assembly (41), a sliding base front-back drive motor (2) and a sliding base left-right drive motor (3). The rear sliding base assembly (41) and the front sliding base assembly (42) are arranged in two separated concave areas (11 and 12) on the machine frame (1) from back to front in a separated mode and are matched with the corresponding concave areas (11 and 12) in a sliding mode. The sliding base front-back drive motor (2) and the sliding base left-right drive motor (3) are both located between the rear sliding base assembly (41) and the front sliding base assembly (42) and fixedly arranged on the machine frame (1).

Owner:ZHEJIANG NORMAL UNIVERSITY

A vibration-absorbing device for connecting joints between assembled concrete columns and newly added steel beams

ActiveCN112227798BMovement restraintIncrease spacingBuilding repairsProtective buildings/sheltersClassical mechanicsSteel tube

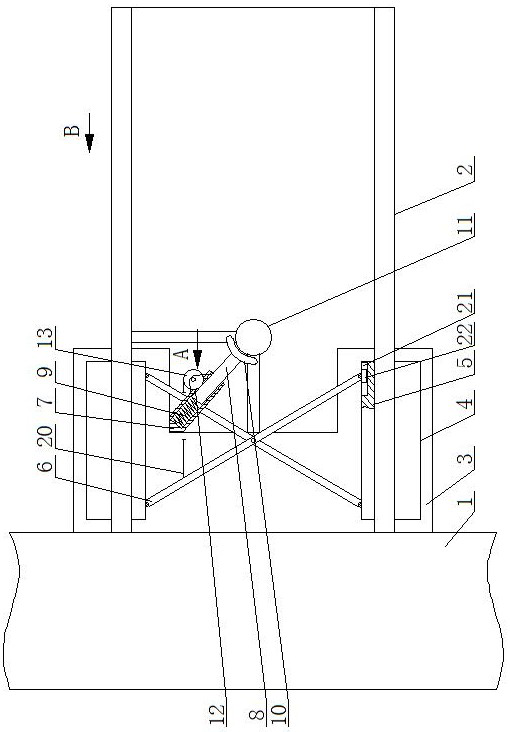

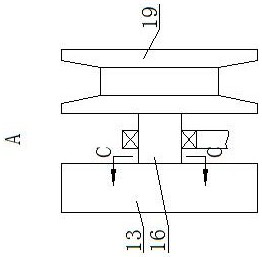

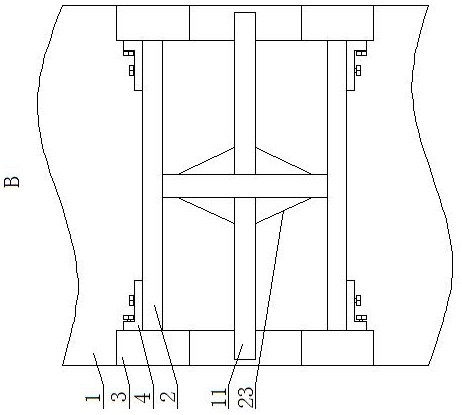

A prefabricated concrete column and newly added steel beam joint joint damping device, including a steel pipe column and a steel beam, the steel beam is equipped with a C-shaped plate on the front and rear sides, and the opening sides of the C-shaped plate are all away from the steel pipe column. The other side of the slab is fixedly connected with the steel pipe column. There are two L-shaped slabs on each C-shaped slab. The L-shaped slabs are located on the opposite sides of the two C-shaped slabs. The steel beams are located between the four L-shaped slabs. And they are respectively connected by bolts. There are two layers on the front and rear sides of the steel beam respectively. The two layers on the front side are connected by a scissor bar, and the two layers on the rear side are connected by the same scissor bar. A sleeve with an open end is fixedly installed inside, and the sleeve is arranged obliquely. The structure can enhance the stability in the horizontal dimension, reduce the cracking of the ground or roof caused by the large-scale movement or even damage of the steel beam, and help to further ensure people's property and personal safety.

Owner:CHONGQING THREE GORGES UNIV

A kind of LED dispensing packaging equipment

InactiveCN104465943BOffset shockImprove processing efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesDrive motorEngineering

Owner:国网山东省电力公司临清市供电公司 +1

Operation method of a hydraulic cylinder cylinder body welding seam welding device

InactiveCN104439873BOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

An operation method of a welding device for a welding joint of a hydraulic cylinder body is characterized in that the welding device comprises a machine frame (1), a front sliding base assembly (42), a rear sliding base assembly (41), a sliding base front and back driving electric motor (2) and a sliding base left and right driving electric motor (3), and the rear sliding base assembly (41) and the front sliding base assembly (42) are separately arranged in two separated concave areas (11 and 12) on the machine frame (1) in the front and back mode and in sliding fit with the concave areas (11 and 12); the sliding base front and back driving electric motor (2) and the sliding base left and right driving electric motor (3) are fixedly arranged between the rear sliding base assembly (41) and the front sliding base assembly (42) and fixedly arranged on the machine frame (1).

Owner:南通欧特建材设备有限公司

A kind of LED dispensing packaging equipment

InactiveCN104319344BOffset shockImprove processing efficiencySemiconductor devicesEngineeringDrive motor

An efficient LED dispensing packaging device comprises a frame (1), a front sliding seat component (42), a rear sliding seat component (41), a longitudinal drive motor (2) and a horizontal drive motor (3). A frame guide rail (19) is longitudinally arranged on the frame (1), and the rear sliding seat component (41) and the front sliding seat component (42) are separately arranged on the frame (1) in a front and back mode and matched with the frame guide rail (19) in a sliding mode; the longitudinal drive motor (2) and the horizontal drive motor (3) are arranged between the rear sliding seat component (41) and the front sliding seat component (42) and fixedly arranged on the frame (1).

Owner:马斯特(佛山)电气照明有限公司

Efficient LED dispensing packaging device

InactiveCN104319344AOffset shockImprove processing efficiencySemiconductor devicesEngineeringDrive motor

An efficient LED dispensing packaging device comprises a frame (1), a front sliding seat component (42), a rear sliding seat component (41), a longitudinal drive motor (2) and a horizontal drive motor (3). A frame guide rail (19) is longitudinally arranged on the frame (1), and the rear sliding seat component (41) and the front sliding seat component (42) are separately arranged on the frame (1) in a front and back mode and matched with the frame guide rail (19) in a sliding mode; the longitudinal drive motor (2) and the horizontal drive motor (3) are arranged between the rear sliding seat component (41) and the front sliding seat component (42) and fixedly arranged on the frame (1).

Owner:马斯特(佛山)电气照明有限公司

A hydraulic cylinder block welding seam welding device with cooling water pipe

ActiveCN104439859BOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

A hydraulic cylinder block weld joint welding device with a cooling water pipe comprises a machine frame (1), a front sliding base assembly (42), a rear sliding base assembly (41), a sliding base front-back drive motor (2) and a sliding base left-right drive motor (3). The rear sliding base assembly (41) and the front sliding base assembly (42) are arranged in two separated concave areas (11 and 12) on the machine frame (1) from back to front in a separated mode and are matched with the corresponding concave areas (11 and 12) in a sliding mode. The sliding base front-back drive motor (2) and the sliding base left-right drive motor (3) are both located between the rear sliding base assembly (41) and the front sliding base assembly (42) and fixedly arranged on the machine frame (1).

Owner:福建省鑫建锋机械制造有限公司

LED adhesive dispensing packaging equipment with good noise removing effect

InactiveCN104465948AOffset shockImprove processing efficiencySemiconductor devicesDrive motorEngineering

The invention discloses LED adhesive dispensing packaging equipment with the good noise removing effect. The equipment comprises a rack (1), a front sliding base assembly (42), a rear sliding base assembly (41), a longitudinal driving motor (2) and a transverse driving motor (3). The rack (1) is longitudinally provided with a rack guide rail (19). The rear sliding base assembly (41) and the front sliding base assembly (42) are arranged on the rack (1) in a front-back separated mode and are in sliding fit with the rack guide rail (19). A rectangular noise removing box (230) is fixedly arranged on the portion, between the rear sliding base assembly (41) and the front sliding base assembly (42), of the rack (1). The longitudinal driving motor (2) and the transverse driving motor (3) are installed in the noise removing box (230) in a left-right separated mode. The noise removing box (230) can achieve the good noise removing effect when the longitudinal driving motor (2) and the transverse driving motor (3) work.

Owner:姚文

A LED dispensing packaging equipment with a heating device

InactiveCN104319338BOffset shockImprove processing efficiencyLiquid surface applicatorsCoatingsAdhesiveDrive motor

An LED adhesive-dispensing package device with a heating device comprises a rack (1), a front slide seat module (42), a rear slide seat module (41), a longitudinal drive motor (2) and a transverse drive motor (3), wherein a rack guide rail (19) is longitudinally arranged on the rack (1), and the rear slide seat module (41) and the front slide seat module (42) are arranged on the rack (1) in a front-rear separated mode and are in sliding fit with the rack guide rail (19). The longitudinal drive motor (2) and the transverse drive motor (3) are arranged between the rear slide seat module (41) and the front slide seat module (42) and are fixedly arranged on the rack (1).

Owner:广州市金隆灯具厂有限责任公司

A hydraulic cylinder body welding seam welding device with lighting device

InactiveCN104439781BOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderDrive motor

Owner:ZHEJIANG NORMAL UNIVERSITY

LED dispensing and packaging device with position sensor and alarm

ActiveCN104384068AOffset shockImprove processing efficiencyLiquid surface applicatorsCoatingsElectric machineryPosition sensor

The invention discloses an LED dispensing and packaging device with a position sensor and an alarm. The LED dispensing and packaging device comprises a rack (1), a front slide seat component (42), a rear slide seat component (41), a longitudinal driving motor (2) and a horizontal driving motor (3), wherein the rack (1) is longitudinally provided with a rack guide rail (19); the rear slide seat component (41) and the front slide seat component (42) are arranged on the rack (1) in a front-and-back separating mode and are matched with the rack guide rail (19) in a matched mode; the longitudinal driving motor (2) and the horizontal driving motor (3) are both positioned between the rear slide seat component (41) and the front slide seat component (42) and are fixedly arranged on the rack (1).

Owner:南通睿博电器有限公司

A LED dispensing packaging equipment with a circular rotating tray

ActiveCN104319339BOffset shockImprove processing efficiencyLiquid surface applicatorsCoatingsAdhesiveDrive motor

An LED adhesive-dispensing package device with a round rotating tray comprises a rack (1), a front slide seat module (42), a rear slide seat module (41), a longitudinal drive motor (2) and a transverse drive motor (3), wherein a rack guide rail (19) is longitudinally arranged on the rack (1), and the rear slide seat module (41) and the front slide seat module (42) are arranged on the rack (1) in a front-rear separated mode and are in sliding fit with the rack guide rail (19). The longitudinal drive motor (2) and the transverse drive motor (3) are arranged between the rear slide seat module (41) and the front slide seat module (42) and are fixedly arranged on the rack (1).

Owner:常熟东南高新技术创业服务有限公司

A dust-proof hydraulic cylinder body welding seam welding device

InactiveCN104439742BOffset shockImpact forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

Owner:LONGHE INTELLIGENT EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com