Linear evaporation source device and precise evaporation rate control evaporating unit with same

A linear evaporation source and evaporation rate technology, applied in vacuum evaporation plating, ion implantation plating, metal material coating process, etc., can solve the problems affecting the quality and life of the device, affecting the uniformity of the coating layer of the glass substrate, etc. To achieve the effect of controlling the uniformity of coating and the concentration of evaporated substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content and structural features of the present invention in detail, further descriptions will be made below in conjunction with the embodiments and accompanying drawings.

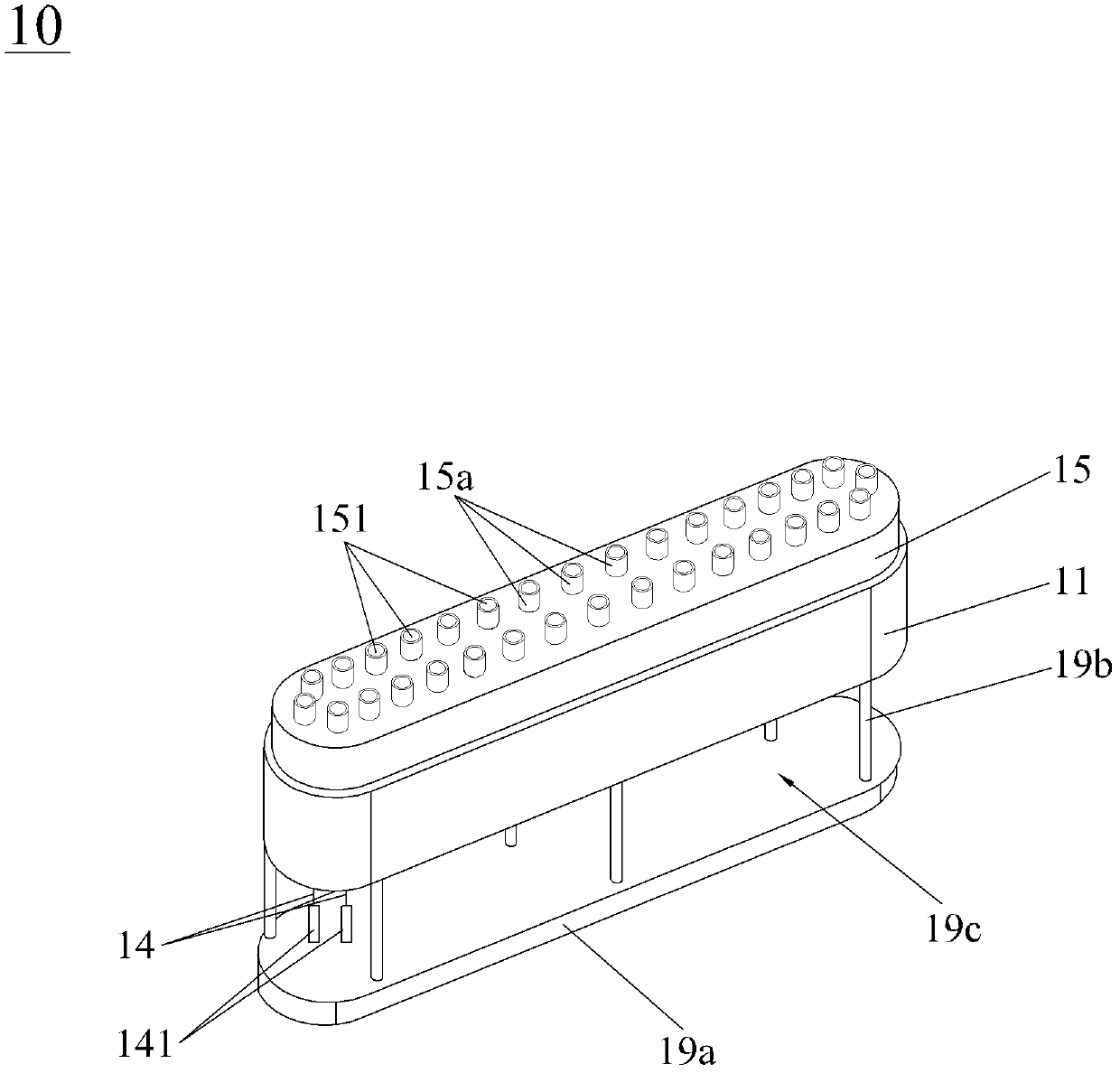

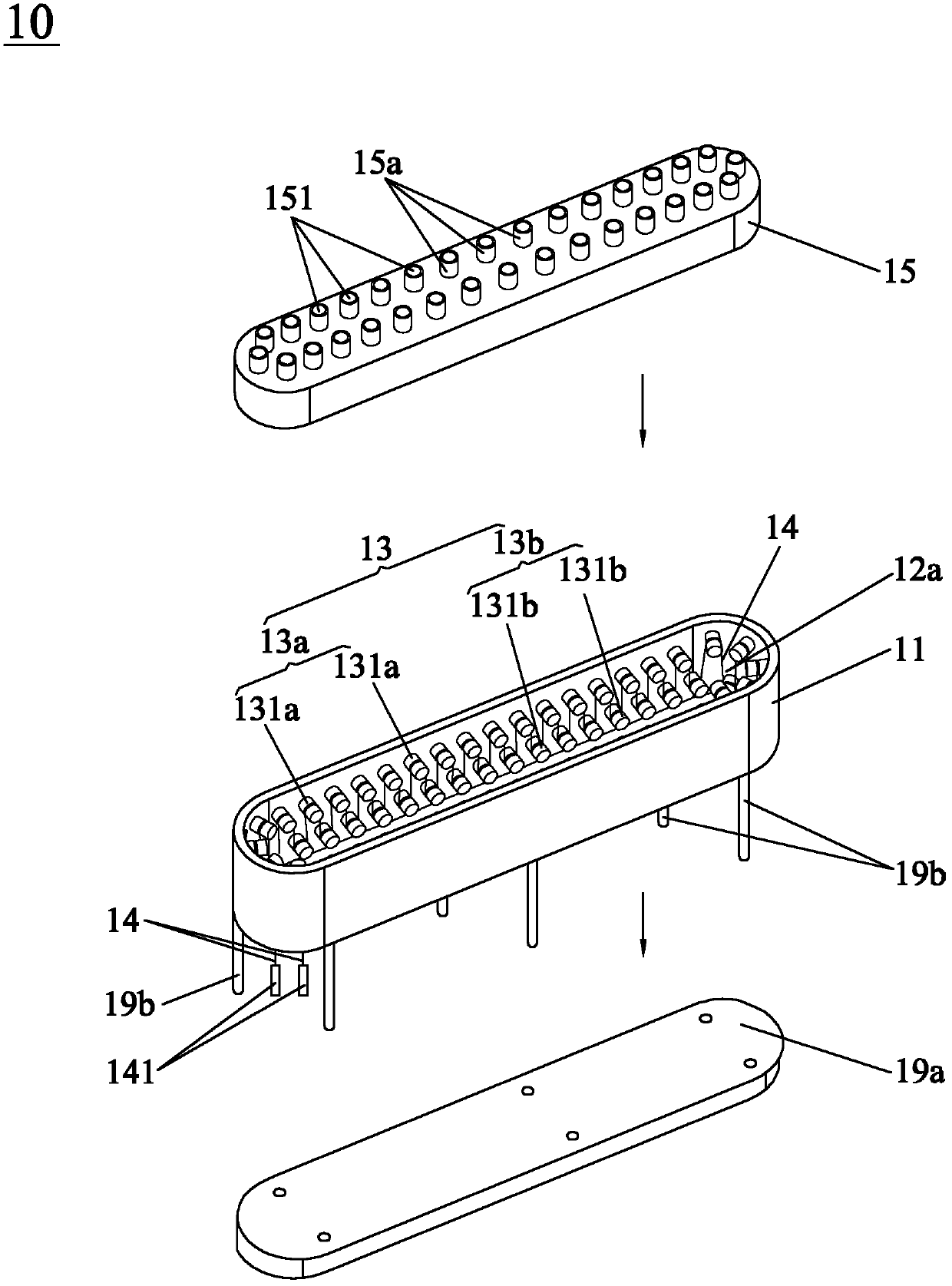

[0029] see figure 1 and figure 2 , the linear evaporation source device 10 of the present invention is used to be arranged in the vacuum chamber 21 of the vacuum chamber body 20 that is a vacuum environment (see Figure 10) to perform linear evaporation on the evaporation source, wherein the linear evaporation source device 10 includes a device body 11 , an insulating sheath assembly 13 , a heating wire 14 and an evaporation cover 15 . The device body 11 is provided with a receiving groove 12a with an upward opening; in this embodiment, the insulating sleeve assembly 13 is fixed in the receiving groove 12a and includes a first horizontal insulating sleeve row 13a and a second horizontal insulating sleeve row 13b, the first horizontal insulating sleeve row 13a inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com