Method for electroplating metal on surface of stephanoporate metal product

A technology of porous metal and electroplating metal, which is applied in the field of electroplating metal on the surface of porous metal products, which can solve problems such as uneven coating and achieve uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

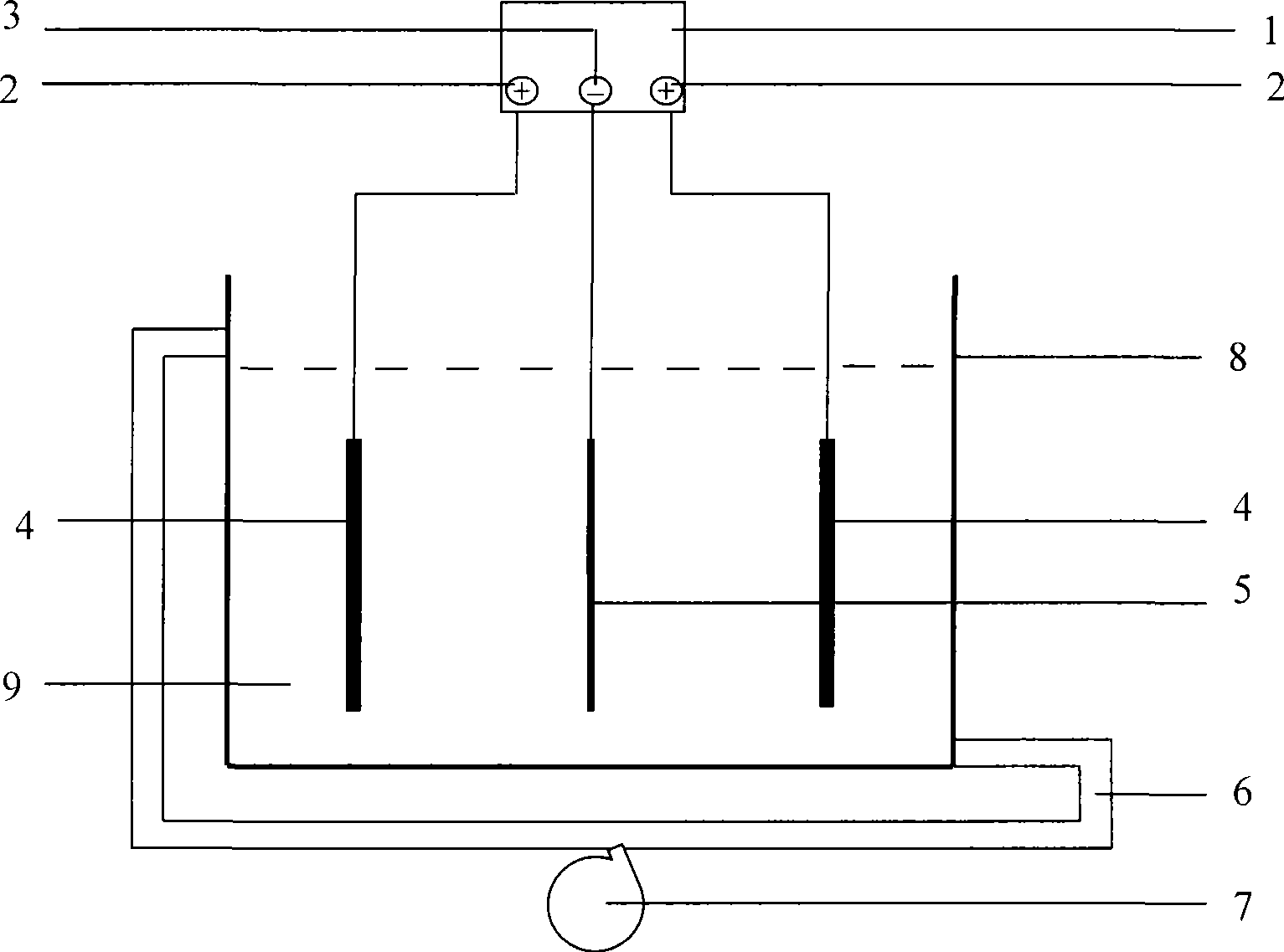

[0018] Platinum-plating a 200×200×0.25mm porous titanium plate with a porosity of 50%. After repeated cleaning with pure water, start the suction filter pump 7, make the flow rate of the electroplating solution 9 be 45L / min, start the ultrasonic generator, the ultrasonic frequency is 20kHz, place the porous titanium plate plated parts on the two platinum-plated titanium mesh anodes 4 Between, the distance between the two platinum-plated titanium mesh anodes 4 is 160mm, the voltage is adjusted to 2.3V, the current is 9A, the electroplating time is 20min, and then the voltage is adjusted to 1.9v, the current is 1.9A, and the electroplating time is 30min, so that the thickness of the platinum coating is It can reach 2μm, and platinum is deposited on the surface and pores of the porous titanium plate to achieve uniform platinum plating.

Embodiment 2

[0020] 200×200×0.25mm porous nickel fiber mat with a porosity of 60% is subjected to platinum plating: first, the surface of the 200×200×0.25mm porous nickel fiber mat with a porosity of 60% is chemically treated to remove oil and surface oxides Finally, after repeated cleaning with pure water, start the suction filter pump 7, so that the flow rate of the electroplating solution 9 is 20L / min, start the ultrasonic generator, the ultrasonic frequency is 30kHz, and place the porous nickel fiber felt on the two platinum-plated titanium mesh anodes. At the position of 5 between 4, the distance between the two anodes is 160mm, the voltage is 2.3V, the current is 9A, the electroplating time is 20min, and then the voltage is adjusted to 1.9v, the current is 1.9A, and the electroplating time is 30min, so that the thickness of the platinum coating is It can reach 2μm, and platinum is deposited on the surface and pores of the porous nickel fiber felt to achieve uniform platinum plating. ...

Embodiment 3

[0022] Apply platinum plating to a 200×200×0.25mm porous stainless steel fiber felt with a porosity of 70%: first, perform surface chemical treatment on a 200×200×0.25mm porous stainless steel fiber felt with a porosity of 70% to remove oil and surface oxides Finally, after repeated cleaning with pure water, start the suction filter pump 7, make the flow rate of the electroplating solution 9 be 30L / min, start the ultrasonic generator, the ultrasonic frequency is 40kHz, and place the porous stainless steel fiber felt on two platinum-coated titanium meshes. Between the anodes 4, the distance between the two platinum-plated titanium mesh anodes 4 is 160mm, the voltage is 2.3V, the current is 9A, the electroplating time is 20min, and then the voltage is adjusted to 1.9v, the current is 1.9A, and the electroplating time is 30min. It can reach 2μm, and platinum is deposited on the surface and pores of the porous stainless steel fiber felt to achieve uniform platinum plating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com