Carbon-based controlled-release fertilizer special for potato and preparation method thereof

A special fertilizer and potato technology, applied in the field of agricultural chemistry, can solve the problems of increasing soil fertility, high cost, few pores and adsorption capacity, etc., and achieve the effect of increasing ground temperature, simple production equipment, and reducing fertilizer leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation process of carbon-based slow-release potato special fertilizer includes mixing various components and granulating with a particle size of 3.35 to 5.0 mm.

[0044] The carbon-based slow-release potato special fertilizer provided by the invention is simple to use and can be used as a special disposable base fertilizer for potato. The preferred application rate of one-time base fertilizer is 40 kg / mu. When sowing, it is applied mechanically at a depth of 12-15 cm under the seed or at a depth of 5-10 cm between two holes without topdressing.

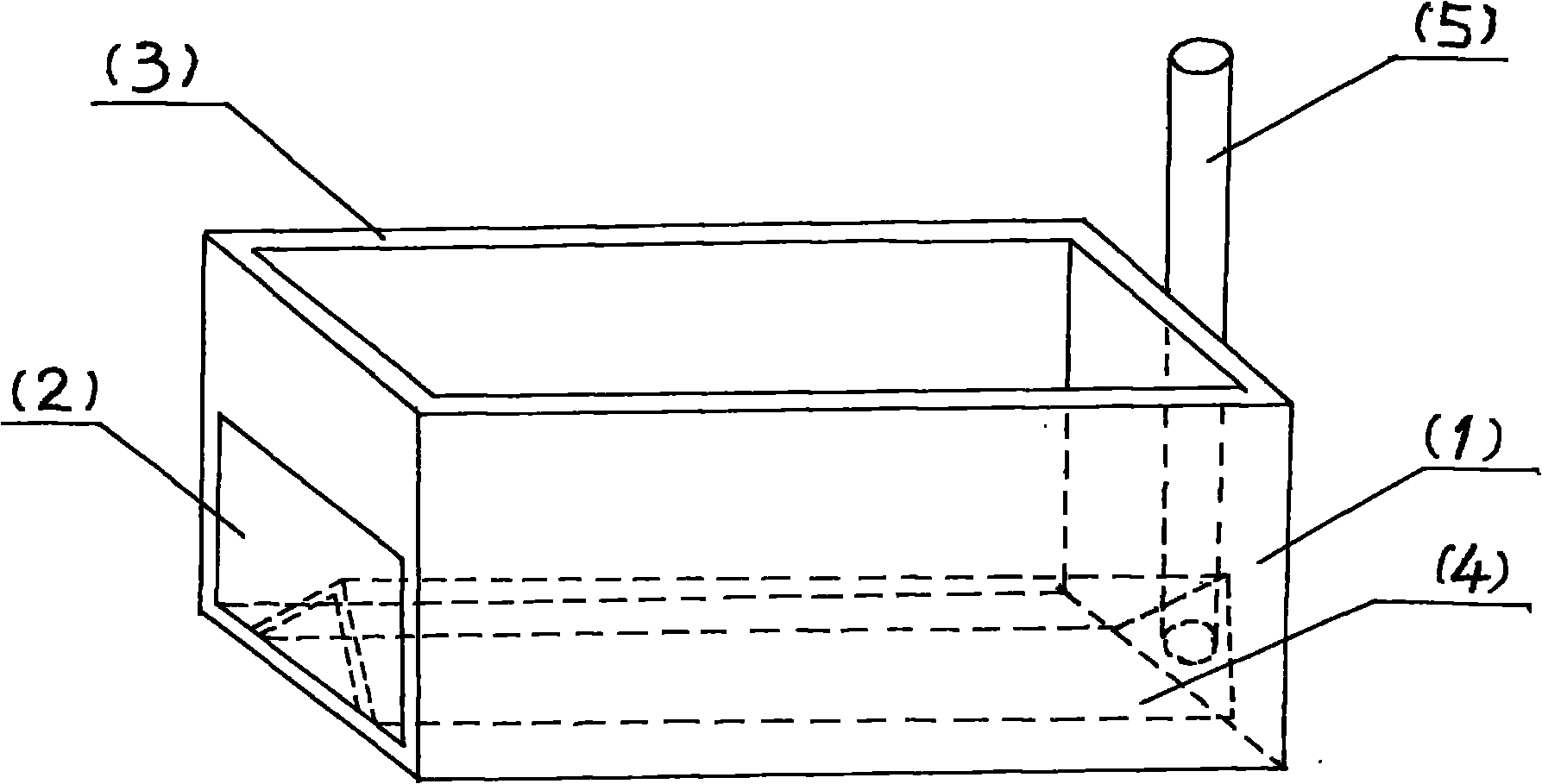

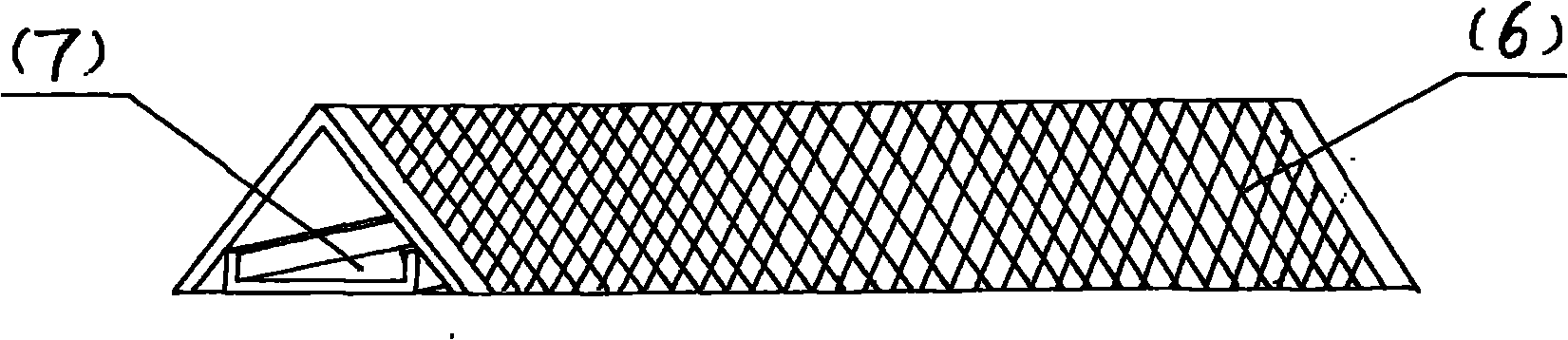

[0045] Preferably, the present invention uses the semi-closed particle carbonization furnace described in the Chinese invention patent with the patent number ZL200710086505.4 (such as figure 1 , 2 (Shown) to produce biomass granular charcoal, as described in the patent, the semi-closed granular carbonization furnace uses an anoxic dry distillation decomposition process under sub-high temperature conditions to produce agricul...

Embodiment 1

[0047] Example 1 Exemplary production method of corncob granular charcoal

[0048] This embodiment exemplarily describes the method of producing corn cob granular charcoal using the semi-closed granular carbonization furnace described in the Chinese invention patent with the patent number ZL200710086505.4, including material selection, material processing, furnace charging, cooling and discharging, Steps such as measuring and packaging, but not limited to this.

[0049] Material selection: Naturally air-dry the corncob of agricultural and sideline products to reduce the moisture content to below 20%.

[0050] Material processing: using any crushing method in the prior art to process and crush the above-mentioned qualified corncob particles, the diameter of the crushed corncob particles is 2-10mm. The crushed corn cob particles can be screened through a sieve, and the corn cob particles that do not meet the requirements can be reprocessed.

[0051] Furnace carbonization: Load the proc...

Embodiment 2

[0055] Example 2 Production method of peanut shell granular carbon

[0056] This embodiment exemplarily describes the method for producing peanut shell granular charcoal using the semi-closed granular carbonization furnace described in the Chinese invention patent with the patent number ZL200710086505.4, including material selection, furnace charging and carbonization, cooling and discharging, metering and packaging, etc. Steps, but not limited to this.

[0057] Material selection: Naturally air-dry the peanut shells of agricultural and sideline products to reduce the water content to below 20%.

[0058] Furnace carbonization: Put the cleaned peanut shells into the furnace body. The initial amount of material added should cover the burner by 10-25 cm. Ignite the ignitor in the burner ignition plate. The pilot fuel is diesel. After the material is ignited, it will continue to spontaneously ignite without external heating source. The material is carbonized under anoxic conditions a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com