Device and method for preparing biomass oil by using waste heat of blast furnace granulated slag

A technology of biomass oil and granulated slag, which is applied in coking ovens, petroleum industry, direct heating and dry distillation, etc., can solve the problems of waste of heat resources and water resources, environmental pollution, etc., achieve strong heat storage capacity, reduce production costs, The effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

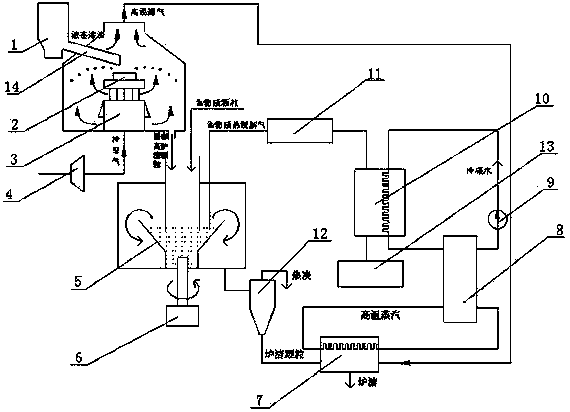

[0029] One, the device for producing biomass oil according to the present invention

[0030] The structure of the device for producing biomass oil by using the waste heat of blast furnace granulated slag according to the present invention is as follows: figure 1 As shown, the device comprises a granulator 2, a fan 4 connected to the granulator 2 and a rotatable rotary cone reactor 5, and the rotary cone reactor 5 is provided with an upper end feed port and an upper end gas outlet and the outlet at the lower end, the gas outlet of the rotating cone reactor is sequentially connected with a first separator 11 and a condenser 10, and the condenser 10 is also connected with an oil storage tank 13 for storing biomass oil.

[0031] The outlet of the rotating cone reactor is sequentially connected with a second separator 12 and a heat exchanger 7, and the granulator 2 is connected with the heat exchanger 7 through a pipe for transmitting high-temperature flue gas, and the heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com