Combined biomass particle carbonization furnace and carbonizing method thereof

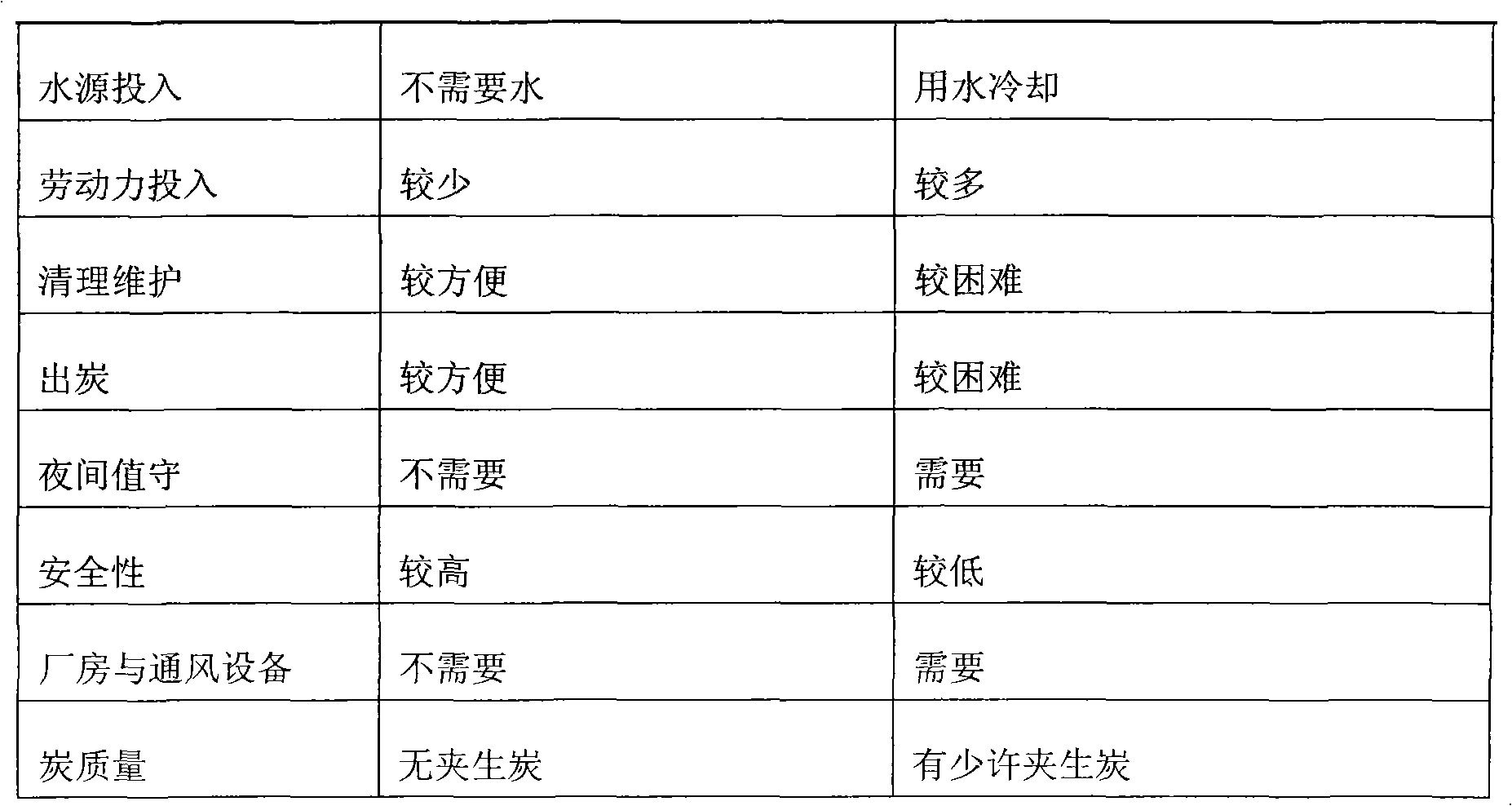

A biomass granular carbon and carbonization furnace technology, applied in the field of agricultural machinery, can solve the problems of inconvenient charcoal discharge, furnace cleaning, maintenance and operation, increased labor input cost, increased transportation cost, etc., and achieves low production cost and environmental requirements. The effect of lower transportation costs and lower labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1 Carbonization Furnace

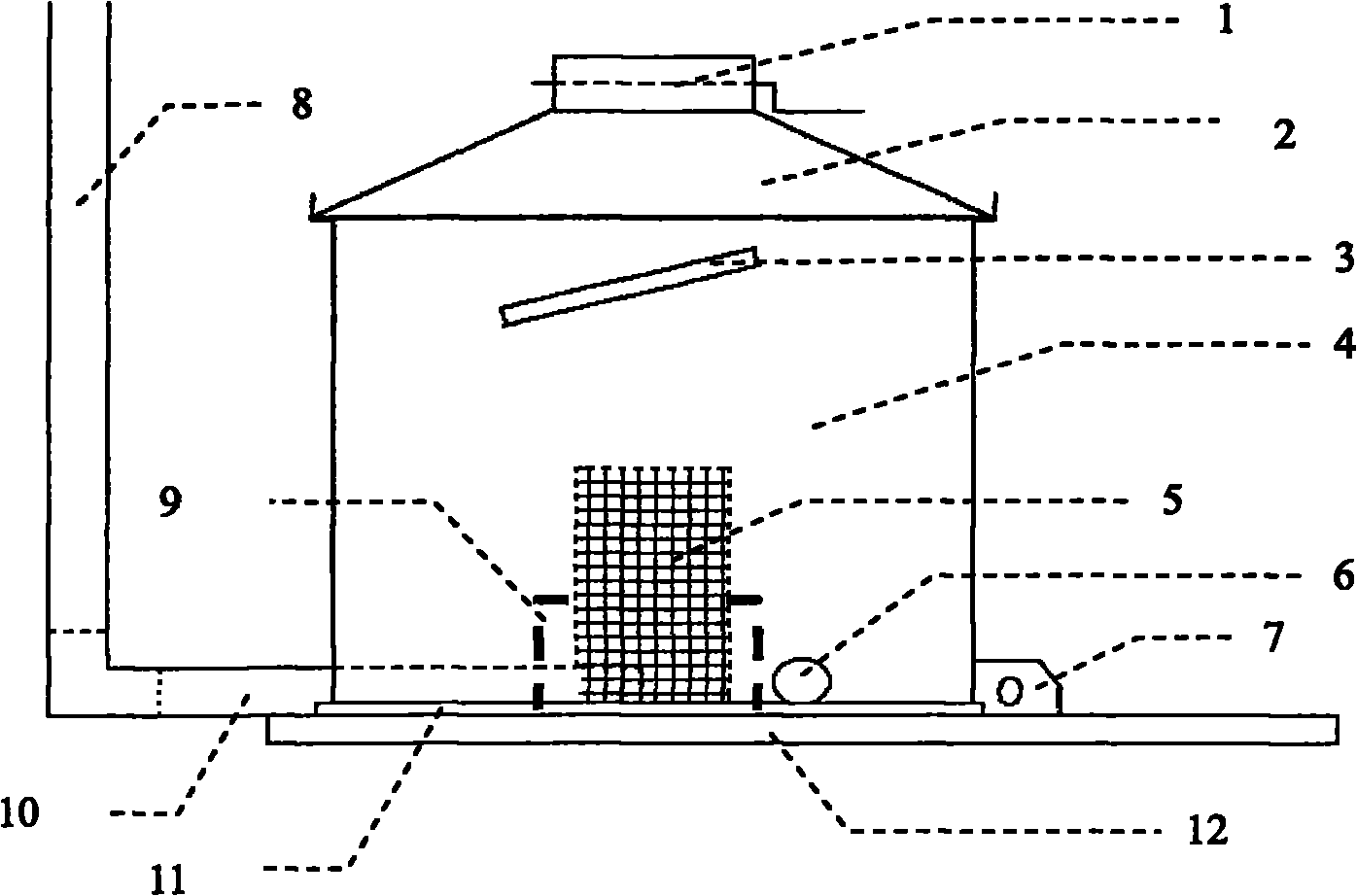

[0056] The carbonization furnace consists of a revolving door 1, a top cover 2, a sleeve 3, a furnace body 4, a burner 5, an air inlet 6, a hinge 7, a longitudinal exhaust pipe 8 and a horizontal exhaust pipe 10, a burner holder 9, Furnace body draw-in slot 11 and base 12 are formed, as figure 1 shown. The exhaust pipe is connected with the water circulation gas condensing system to recycle wood vinegar. The carbonization furnace furnace body 4 is an 8mm thick double-layer steel plate, with asbestos silk as the middle insulation interlayer. The body of the furnace is cylindrical, 120cm high and 120cm in diameter. The sleeve on the outer upper part of the furnace body is 30cm long, with an inner diameter of 4cm, and forms an angle of 30 degrees with the horizontal plane. The air inlet is 14cm in diameter and is closed by a circular air inlet cover. The diameter of the exhaust port is 14cm, which is closely connected with the exhaust...

Embodiment 2

[0060] Example 2 Carbonization Furnace

[0061] This embodiment is substantially the same as Embodiment 1, except that the body of furnace is made of 4mm steel plate. The size of each component is reduced by one time according to the proportion of embodiment 1.

Embodiment 3

[0062] Example 3 Carbonization Furnace

[0063] This embodiment is substantially the same as Embodiment 1, except that the furnace body is made of 10mm steel plates without interlayer. The size of each component is doubled according to the proportion of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com