Process of preparing rich acetone alcohol biological oil by biomass microwave catalytic pyrolysis

A microwave catalysis and biomass technology, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, organic chemistry, etc., can solve the problems of high raw material cost, expensive catalyst, low acetol content, etc., achieve shortened reaction time, cheap and easy catalyst The effect of high selectivity generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

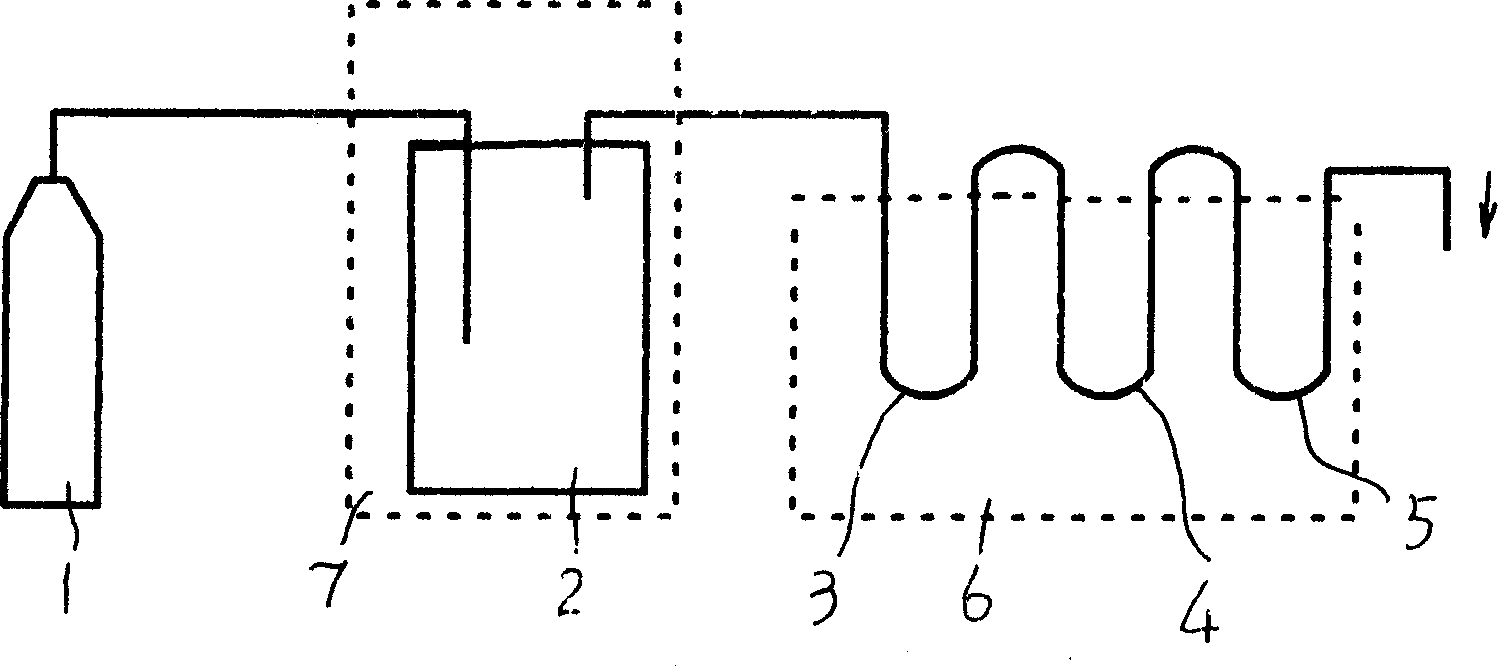

Method used

Image

Examples

Embodiment 1

[0030] Using pine sawdust as raw material, it is crushed to a particle size of less than 1 mm, and the method of the present invention is used for raw material preparation, charging, air exhausting and microwave cracking. The cracking time is 12 minutes, and the liquid product is collected. The yield of the liquid product was 22.0%, the content of acetol was 45.3%, and the water content was 28.2%.

Embodiment 2

[0032] Using cotton stalk sawdust as raw material, the same steps as in Example 1 were used to collect the liquid product. The yield of the liquid product was 15.8%, the acetol content was 49.9%, and the water content was 30.3%.

Embodiment 3

[0034] Using Chinese fir sawdust as raw material, adopt the same steps as in Example 1 to collect the liquid product. The yield of the liquid product was 24.7%, the content of acetol was 45.4%, and the water content was 29.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com