Synthetic gas conversion coupling catalyst and use thereof

A synthesis gas conversion and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

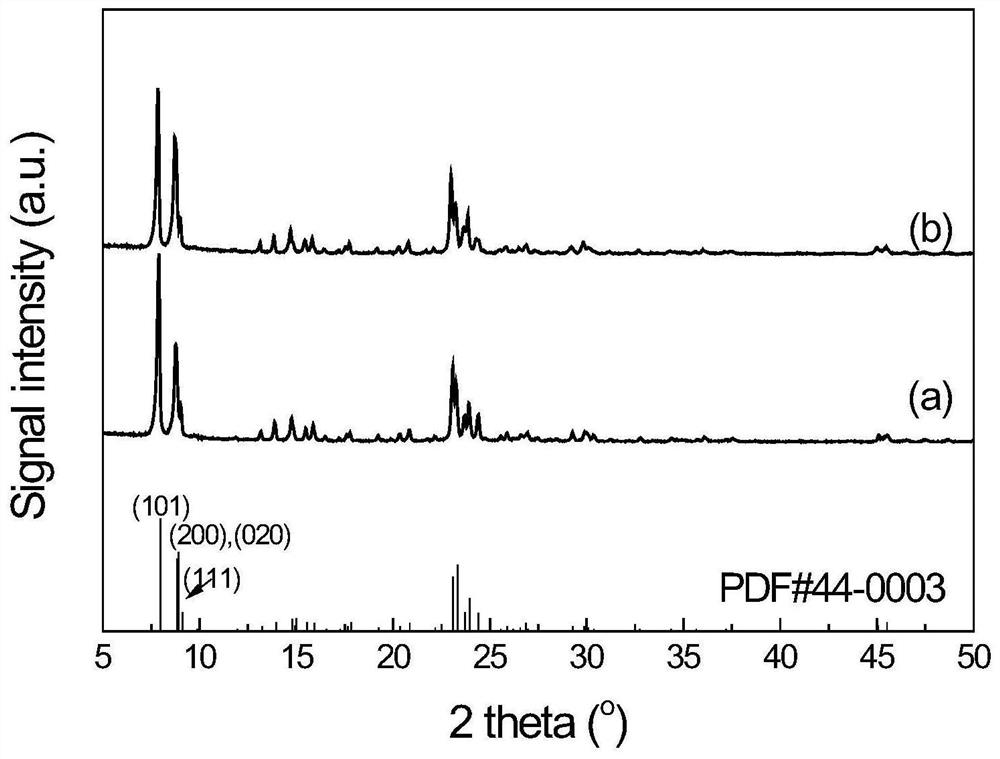

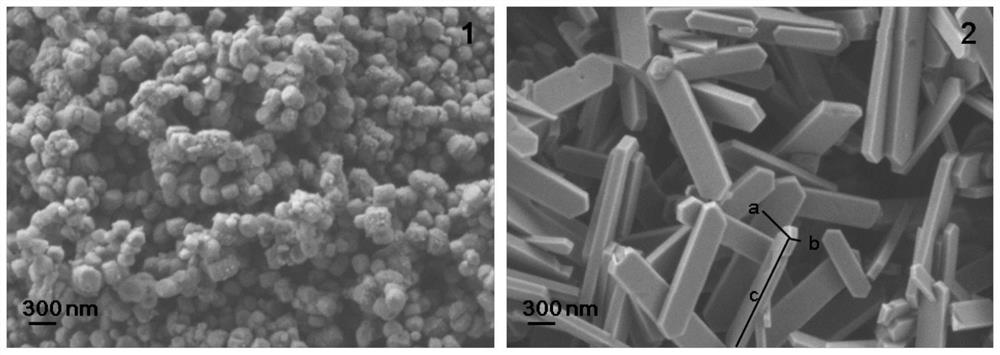

[0044] Preparation of Cr by precipitation method 2 o 3 , the H-ZSM-5 molecular sieve with Si / Al ratio of 50 was synthesized by hydrothermal method. The XRD spectrum pattern of gained H-ZSM-5 is as figure 1 As shown, the characteristic peaks of the MFI structure can be seen in the spectrogram, and it can be observed that the intensity ratio of the diffraction peaks of the (101) crystal plane (2θ=7.972°) and the (200) crystal plane (2θ=8.818°) is lower than that of the H - ZSM-5 molecular sieve. The SEM photograph of gained H-ZSM-5 is as figure 2 As shown, it can be observed that the molecular sieve has a sheet-like morphology, and the dimensions of the a, b, and b axes are 600 nm, 100 nm, and 1500 nm, respectively. Cr 2 o 3 Mechanically mix with H-ZSM-5 at a mass ratio of 1:2, crush to 20-40 mesh after tableting, weigh 1.5g and fill in the reactor. At a reaction temperature of 395°C and a pressure of 4.0MPa, the feed gas H 2 / CO ratio 1.0, airspeed 2000h -1 Catalyst e...

Embodiment 2

[0047] MnO was prepared by precipitation method, and H-ZSM-5 molecular sieves with Si / Al ratio of 50 and a, b and b axis sizes of 600nm, 100nm and 1500nm were synthesized by hydrothermal method. MnO and H-ZSM-5 were mechanically mixed at a mass ratio of 1:2, crushed to 20-40 mesh after tableting, and 1.5 g was weighed and loaded into the reactor. At a reaction temperature of 395°C and a pressure of 4.0MPa, the feed gas H 2 / CO ratio 1.0, airspeed 2000h -1 Catalyst evaluation was carried out under the conditions. Before the reaction, the catalyst was heated with H at 395°C 2 Pretreatment 2h. CO conversion, aromatics selectivity, C 6 -C 8 The results of aromatics selectivity are shown in Table 1.

Embodiment 3

[0049] MnO was prepared by high-temperature sintering method, and H-ZSM-5 molecular sieves with Si / Al ratio of 30 and a, b, and b axis sizes of 1600nm, 500nm, and 5000nm were synthesized by hydrothermal method. MnO and H-ZSM-5 were mechanically mixed at a mass ratio of 1:2, crushed to 20-40 mesh after tableting, and 1.5 g was weighed and loaded into the reactor. At a reaction temperature of 395°C and a pressure of 4.0MPa, the feed gas H 2 / CO ratio 1.0, airspeed 2000h -1 Catalyst evaluation was carried out under the conditions. Before the reaction, the catalyst was heated with H at 395°C 2 Pretreatment 2h. CO conversion, aromatics selectivity, C 6 -C 8 The results of aromatics selectivity are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com