Bismuth reverberatory retaining wall castable for smelting

A furnace retaining wall and castable technology, which is applied in the field of refractory materials, can solve the problems of poor integrity of the reverberatory furnace retaining wall, low corrosion resistance strength, and poor thermal shock resistance, so as to reduce the working time of materials and personnel, and improve heat resistance. Good shock stability and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

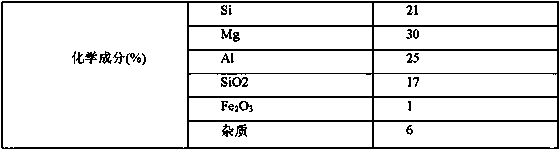

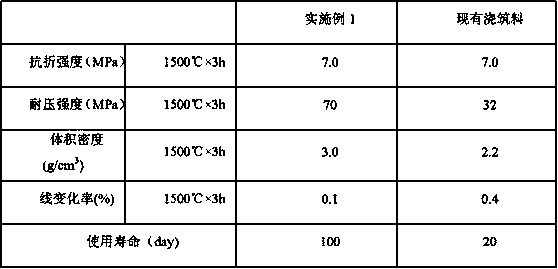

[0020] A bismuth reverberatory furnace retaining wall castable for smelting is made of the following raw materials in parts by weight: the first component: 50 parts and the second component: 40 parts; the first component is composed of the following parts by weight made of raw materials: 34 parts of spinel, 15 parts of metal aluminum, 17 parts of metal silicon and 38 parts of chrome corundum; the second component is made of the following raw materials in parts by weight: 15 parts of suspending agent and bonding 75 parts of agent; Suspending agent is guar gum; Binding agent is silica sol; The crystal size of described chrome corundum is 600um, and Al in described chrome corundum 2 o 3 The content of Cr is 97.4%. 2 o 3 The content of 2.0%, Na 2 The content of O is 0.55%, the balance is impurities, and the bulk density is 1.40g / cm3. The particle size of metallic aluminum is 200 orders, bulk density 2.7g / cm3; The particle size of described metallic silicon is 200 orders, and t...

Embodiment 2

[0027] A bismuth reverberatory furnace retaining wall castable for smelting is made of the following raw materials in parts by weight: the first component: 55 parts and the second component: 45 parts; the first component consists of the following parts by weight Made of raw materials: 38 parts of spinel, 19 parts of metal aluminum, 19 parts of metal silicon and 39 parts of chrome corundum; the second component is made of the following raw materials in parts by weight: 20 parts of suspending agent and bonding 80 parts of agent; Suspending agent is guar gum; Binding agent is silica sol; The crystal size of described chrome corundum is 700um, and Al in described chrome corundum 2 o 3 The content of Cr is 97.7%. 2 o 3 The content of 1.5%, Na 2 The content of O is 0.5%, the balance is impurities, and the bulk density is 1.655g / cm3. The particle size of metal aluminum is 250 orders, bulk density 3.2g / cm 3 .

[0028] The reverberatory furnace retaining wall made by using the sp...

Embodiment 3

[0034] A bismuth reverberatory furnace retaining wall castable for smelting is made of the following raw materials in parts by weight: the first component: 60 parts and the second component: 50 parts; the first component is composed of the following parts by weight Made of raw materials: 42 parts of spinel, 23 parts of metal aluminum, 21 parts of metal silicon and 40 parts of chrome corundum; the second component is made of the following raw materials in parts by weight: 25 parts of suspending agent and bonding 85 parts of agent; Suspending agent is guar gum; Binding agent is silica sol; The crystal size of described chrome corundum is 800um, and Al in described chrome corundum 2 o 3 The content of Cr is 97.6%. 2 o 3 The content of 1.0%, Na 2 The content of O is 0.3%, the balance is impurities, and the bulk density is 1.91g / cm3. The particle size of metallic aluminum is 300 orders, bulk density 3.7g / cm3; The particle size of described metallic silicon is 300 orders, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com