Cement-based shrinkage-free grouting mortar

A non-shrinkage, cement-based technology, applied in the field of building materials, can solve the problems of high cement cost, unsuitable promotion, insufficient expansion performance, etc., and achieve the effects of good self-flow, low price and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of cement-based non-shrinkage grouting mortar, by weight percentage, it comprises:

[0028] Cementitious material: PO42.5R cement 38%, CA-50 cement 5%, natural raw gypsum 6%;

[0029] Aggregate: medium coarse yellow sand 48.5%;

[0030] High-efficiency water reducer: naphthalenesulfonate formaldehyde condensate 1%;

[0031] Coagulation regulator: lithium carbonate 0.01%, sodium gluconate 0.05%, tartaric acid 0.04%;

Embodiment 2

[0035] A kind of cement-based non-shrinkage grouting mortar, by weight percentage, it comprises:

[0036] Cementitious material: PO42.5R cement 35%, CA-50 cement 8%, natural raw gypsum 7.4%;

[0037] Aggregate: medium coarse yellow sand 45%;

[0038] High-efficiency water reducer: 1.4% mixture of naphthalenesulfonate formaldehyde condensation product water reducer and sulfamate water reducer;

[0039] Coagulation regulator: lithium carbonate 0.02%, sodium gluconate 0.1%, tartaric acid 0.08%;

Embodiment 3

[0043] A kind of cement-based non-shrinkage grouting mortar, by weight percentage, it comprises:

[0044] Cementitious material: PO42.5R cement 42%, CA-50 cement 5%, natural raw gypsum 8%;

[0045] Aggregate: medium coarse yellow sand 40%;

[0046] High-efficiency water reducer: sulfamate water reducer mixture 1.2%;

[0047] Coagulation regulator: lithium carbonate 0.02%, sodium gluconate 0.05%, tartaric acid 0.08%;

[0048] Silicon defoamer: silicone defoamer 0.65%;

[0049] Anti-bleeding agent: 3% slaked lime powder.

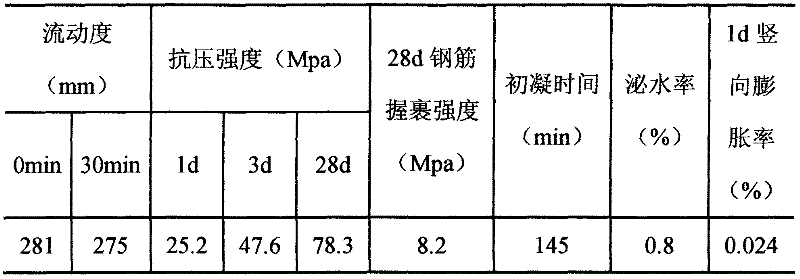

[0050] The portland cement-aluminate cement-gypsum composite cementitious material used in the cement-based non-shrinkage grouting mortar itself has the properties of early strength, high strength and micro-expansion, and the performance is adjustable. The ratio of raw materials can be adjusted according to different user requirements to meet different requirements. For example, the strength of 1d can be high or low (20MPA~40MPA), the strength of 28d (70M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com