Anti-cracking refractory castable for kiln and preparation method of anti-cracking refractory castable

A refractory castable and anti-cracking technology, which is applied in the field of refractory materials, can solve the problems of castable strength reduction and cracking, and achieve the effects of preventing cracking, reducing water addition, and enhancing explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

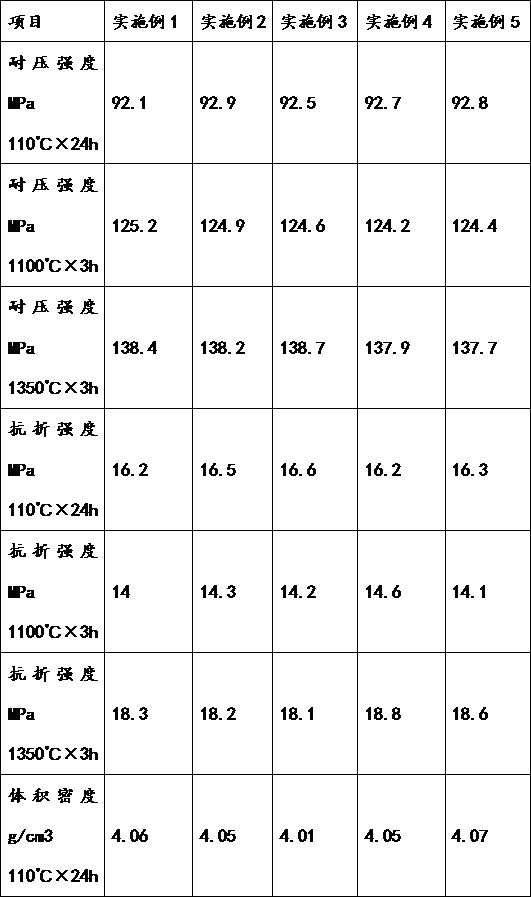

Examples

preparation example Construction

[0020] The preparation method of the anti-cracking refractory castable for the kiln comprises the following preparation steps:

[0021] (1) Mix the raw materials of the anti-cracking refractory castable for kiln, stir evenly, pour and vibrate and form and dry naturally for 1-3 days to obtain the body of anti-cracking refractory castable for kiln;

[0022] (2) Dry the body of the anti-cracking refractory castable for kiln at a high temperature of 110-130° C. for 12-36 hours, and cool it at room temperature to obtain the anti-cracking refractory castable for kiln.

Embodiment 1

[0024] An anti-cracking refractory castable for a kiln, comprising the following raw materials in parts by weight: 30 parts of alumina ceramic whiskers, 5 parts of silicon carbide whiskers, 3 parts of aluminum carbide whiskers, 8 parts of silicon oxide whiskers, 4 parts of basalt fiber, 0.2 parts of sodium tripolyphosphate, 1 part of polydimethylsiloxane, 3 parts of aluminum silicate cement, 20 parts of deionized water. Wherein, the average diameter of the alumina ceramic whiskers is 40 μm, the average diameter of the silicon carbide whiskers is 10 μm, the average diameter of the aluminum carbide whiskers is 30 μm, and the average diameter of the silicon oxide whiskers is 5 μm , the average diameter of the basalt fiber is 2 μm, and the average length is 60 μm.

[0025] The preparation method of the anti-cracking refractory castable for the kiln comprises the following preparation steps:

[0026] (1) Mix the raw materials of the anti-cracking refractory castable for kiln, stir...

Embodiment 2

[0029] An anti-cracking refractory castable for a kiln, comprising the following raw materials in parts by weight: 40 parts of alumina ceramic whiskers with an average diameter of 50 μm, 7 parts of silicon carbide whiskers, 4 parts of aluminum carbide whiskers, 13 parts of oxide Silicon whiskers, 5 parts of basalt fiber, 0.3 parts of sodium tripolyphosphate, 1.5 parts of polydimethylsiloxane, 6 parts of aluminum silicate cement, 30 parts of deionized water. Wherein, the average diameter of the alumina ceramic whiskers is 50 μm, the average diameter of the silicon carbide whiskers is 15 μm, the average diameter of the aluminum carbide whiskers is 35 μm, and the average diameter of the silicon oxide whiskers is 7 μm , the average diameter of the basalt fiber is 5 μm, and the average length is 70 μm.

[0030] The preparation method of the anti-cracking refractory castable for the kiln comprises the following preparation steps:

[0031] (1) Mix the raw materials of the anti-crack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com