Converter steel-tapping hole pumping and casting repair equipment and casting repair method

A tapping hole and converter technology, which is applied in the field of pumping and pouring repair equipment for converter tapping holes, can solve problems such as damage to the lining of red-hot bricks, low life span of the tapping hole, and inability to resist slag erosion, and achieve equipmentization and safety. , The effect of simple construction operation and high anti-explosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

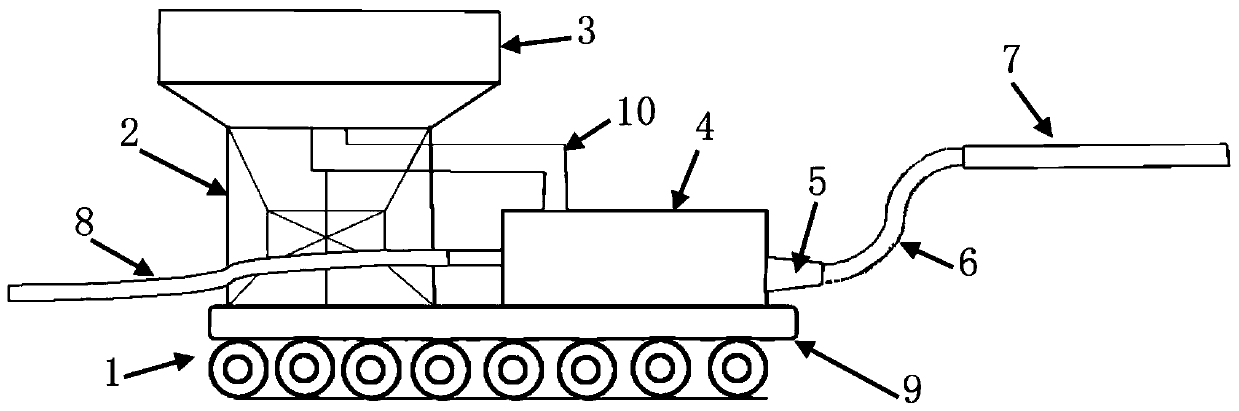

[0033] like figure 1 As shown, the embodiment of the present invention provides a converter taphole pumping pouring repair equipment, including: a carrying platform 1, a support frame 2 is fixed on the carrying platform 1, and a storage device 3 is fixed on the support frame 2 The material storage device 3 is connected to the feed port of the pumping device 5 through the feeding device 4, and the discharge port of the pumping device 5 is connected to the heat preservation chute 7 through the discharge pipe 6; the feeding device 4 and the The pumping device 5 is fixed on the carrying platform 1; the conveying device 4 is also connected with a high-pressure gas source through a high-pressure gas pipe 8 .

[0034] The carrying platform 1 is a carrying trolley, including active steering wheels, driven wheels, power transmission shafts, car body carrying platforms 9, support frames / plates, motor reducer components, and direction control rods;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com