dry grout

A grouting material and dry material technology, applied in the field of building materials, can solve the problems of affecting the construction period, slow curing, material strength loss, etc., and achieve the effect of good early strength performance, good fluidity performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A grout dry material includes the following components:

[0016] 42.5# Ordinary Portland cement is 300kg, aluminate cement is 5kg, quartz sand is 500kg, CSA expansion agent is 5kg, lithium carbonate is 0.05kg, calcium formate is 0.5kg, polycarboxylate superplasticizer with polyester structure It is 1kg.

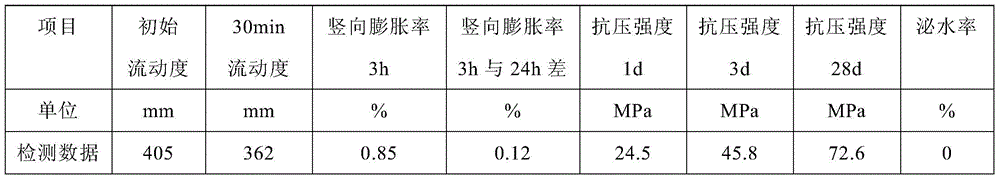

[0017] Add 140-160 kg of water to the dry material of the grouting material and stir evenly to obtain the grouting material slurry, which can be grouted according to actual needs. The performance parameters of the grout made with this ratio are shown in Table 1.

[0018] Table 1

[0019]

Embodiment 2

[0021] A grout dry material includes the following components:

[0022] 42.5# Ordinary Portland cement is 400kg, aluminate cement is 10kg, quartz sand is 600kg, CSA expansion agent is 8kg, lithium carbonate is 0.10kg, calcium formate is 1.0kg, polycarboxylate superplasticizer with polyester structure is 2kg.

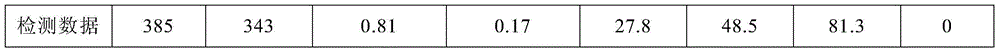

[0023] Add 140-160 kg of water to the dry material of the grouting material and stir evenly to obtain the grouting material slurry, which can be grouted according to actual needs. The performance parameters of the grout made with this ratio are shown in Table 2.

[0024] Table 2

[0025]

[0026]

Embodiment 3

[0028] A grout dry material includes the following components:

[0029] 42.5# Ordinary Portland cement is 320kg, aluminate cement is 7kg, quartz sand is 550kg, CSA expansion agent is 5kg, lithium carbonate is 0.06kg, calcium formate is 0.7kg, polycarboxylate superplasticizer with polyester structure It is 1.5kg.

[0030] Add 140-160 kg of water to the dry material of the grouting material and stir evenly to obtain the grouting material slurry, which can be grouted according to actual needs. The performance parameters of the grout made with this ratio are shown in Table 3.

[0031] table 3

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com