Al2O3-SiO2-SiC-based jet material for foundry ladle

A technology of al2o3-sio2-sic and spraying material, which is applied in the field of Al2O3-SiO2-SiC refractory materials, can solve the problems of reducing material corrosion resistance and unreasonable powder matching, and achieve high strength, good thermal shock stability, The effect of promoting sintering

Inactive Publication Date: 2010-08-25

BAOSHAN IRON & STEEL CO LTD

View PDF2 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

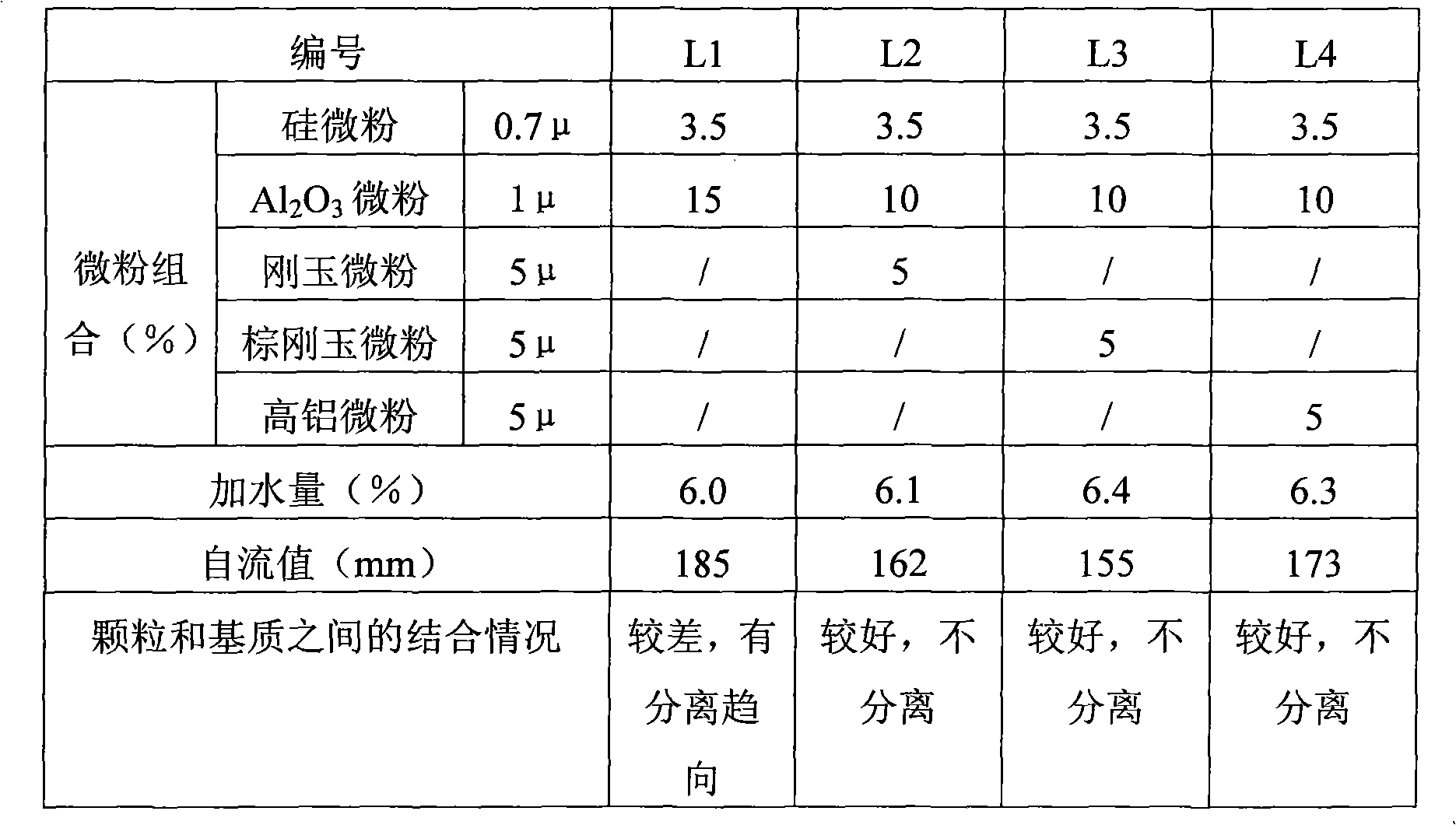

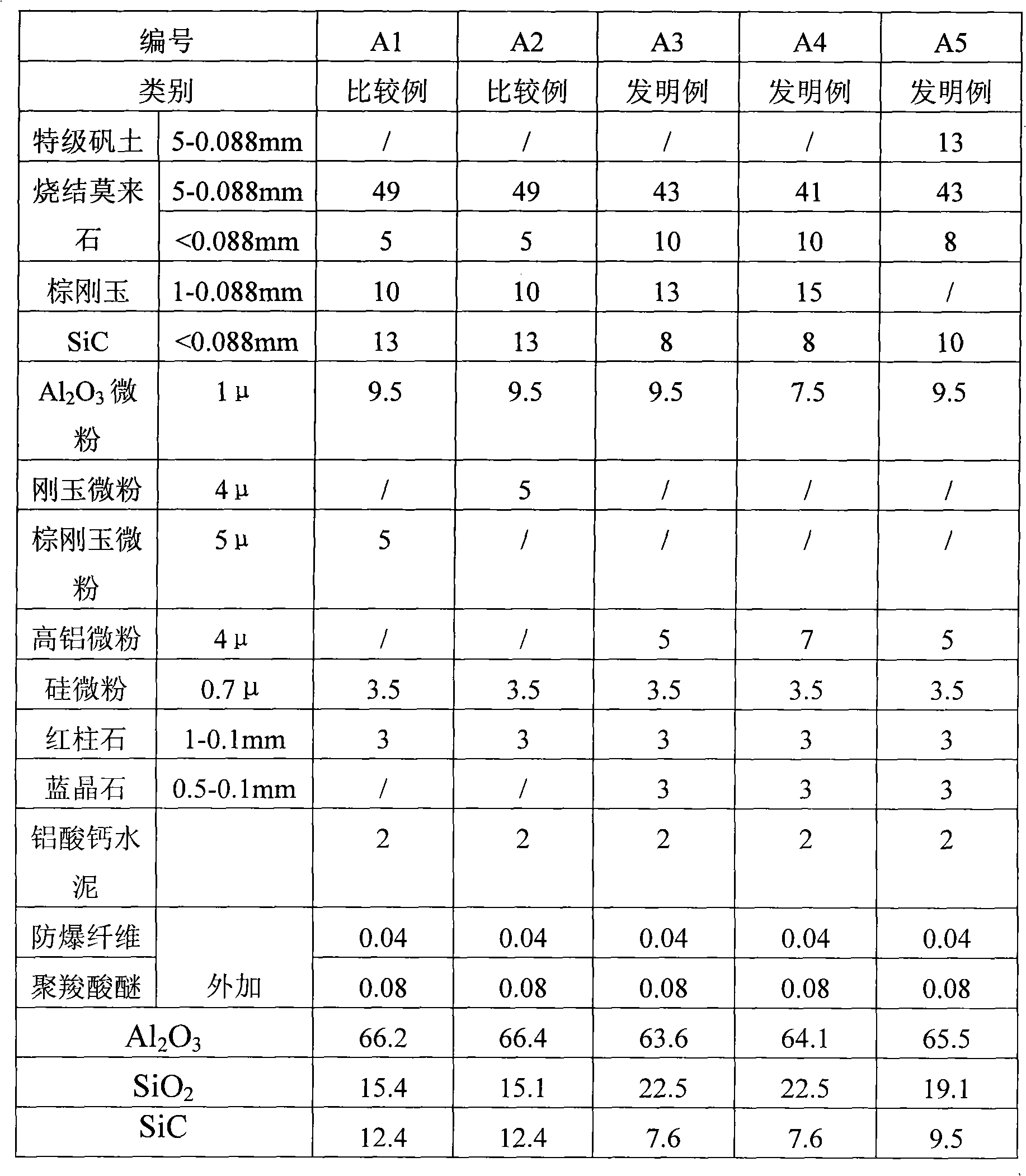

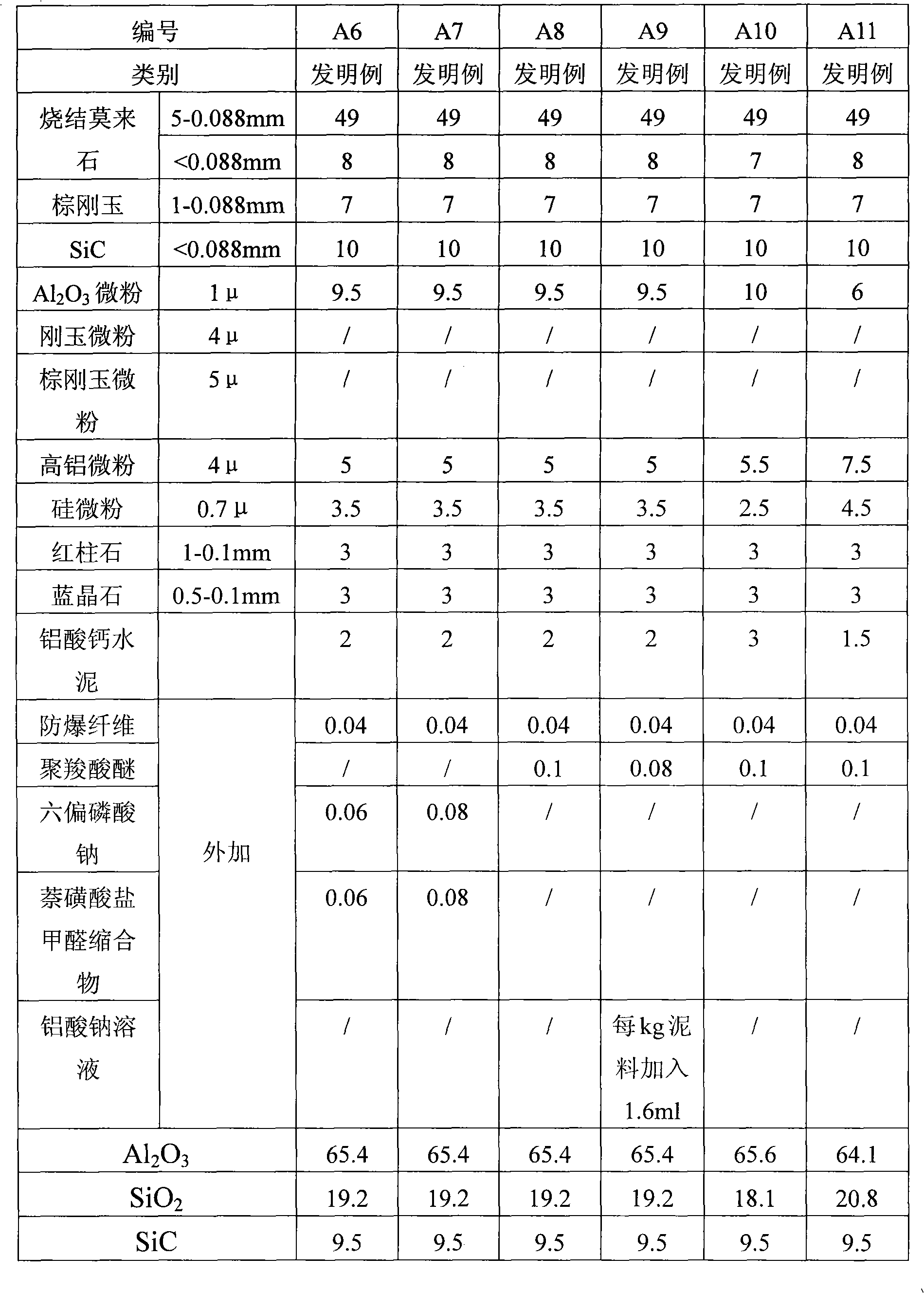

The goal of this patent is to be used for permanent lining. Although the injection material has achieved high strength, if it is used for working lining, the fine powder combination is unreasonable, and the addition of a large amount of high-alumina fine powder will reduce the erosion resistance of the material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an Al2O3-SiO2-SiC-based refractory material, in particular to an Al2O3-SiO2-SiC-based jet material for wet jet construction of a foundry ladle. The Al2O3-SiO2-SiC-based jet material for the foundry ladle comprises the following components in percentage by weight: 45 to 65 percent of sintered mullite, 5 to 15 percent of SiC, 7 to 18 percent of brown aluminium oxide or special-grade alumina, 5 to 10 percent of Al2O3 super-micro powder, 4 to 8 percent of high-aluminum micro powder, 2 to 5 percent of silicon micro powder, 1.5 to 3 percent of calcium aluminate cement, and 6 percent of balance. The granularity of the Al2O3 super-micro powder is leas than or equal to 2 microns; the purity of Al2O3 in the high-aluminum micro powder is more than or equal to 88 percent, and the granularity is less than or equal to 5 microns; and the purity of SiO2 in the silicon micro powder is more than or equal to 92 percent, and the granularity is less than 1 micron. The balance comprises 3 percent of andalusite and 3 percent of cyanite. The jet material has high strength and good thermal shock stability and corrosion resistance, and ensures good self-flowing property and pumping property.

Description

technical field The present invention relates to an Al 2 o 3 -SiO 2 - SiC refractory materials, especially Al for ladle wet spraying construction 2 o 3 -SiO 2 -SiC injection material. Background technique The wet spraying construction of refractory materials can be used not only to construct new refractory linings, but also to repair old linings, and wet spraying construction has many advantages, so this method has been more and more widely used in the iron and steel industry in recent years . The ladle is an important tool for transferring molten iron. When the molten iron is dumped, the lower part of the ladle and the refractory lining at the bottom will be strongly scoured. During the production process, the molten iron contained in the ladle will continue to scour and wear the lining. During slag removal, slag removal and pouring of molten iron, the ladle mouth refractory material is extremely vulnerable to wear. In addition, frequent loading and pouring of molt...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/66C04B7/32C04B14/04

Inventor 姚金甫方善华田守信汪宁伍春芳陈向东

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com