Filling process for recovering coal pillars by filling goaf with paste

A paste filling and goaf technology, which is applied in the fields of filling, mining equipment, earthwork drilling, etc., can solve the problems of shallow burial and waste of coal resources, and achieve the effect of low cost and optimized technical index value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below in conjunction with embodiment further illustrate.

[0063] The weight ratio of each component of the paste material used in this embodiment is: aeolian sand: 67%, fly ash: 12.8%, cement: 3.2%, additive: 0.5%, water: 16.5%.

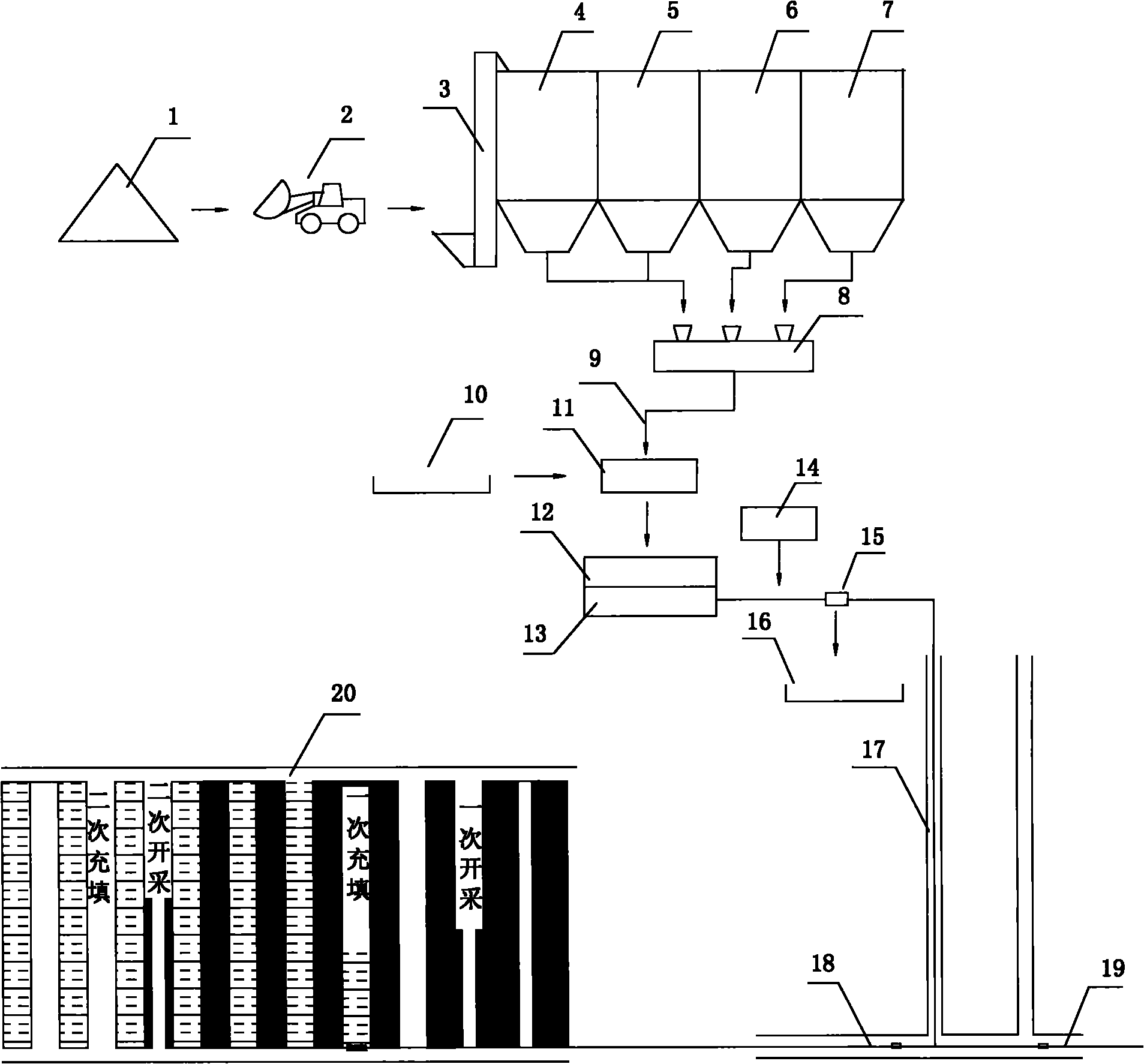

[0064] figure 1 The composition structure and flow diagram of each part of the present invention are given.

[0065] The aeolian sand is transported from the sand field 1 to the filling station through the loader, and stored in the aeolian sand silo 4 through the hoist 3, and the fly ash is stored in the fly ash silo 5, and the cement is stored in the cement silo 6. The additives are stored in the additive silo 7, and the building pool 10 is used to store water. After confirming the start of filling, the weight of the paste main material and auxiliary materials is determined according to the ratio through the computer batching system, and the main paste materials and auxiliary materials are transported to the mixer 11 by each silo through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com