Method for producing portland cement for road by blending iron ore beneficiation tailings in cement

A technology for road silicate and iron ore is applied in the field of road portland cement production, which can solve the problem of low road cement strength, and achieve the effects of considerable economic benefits, reduction of production costs, and consumption savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

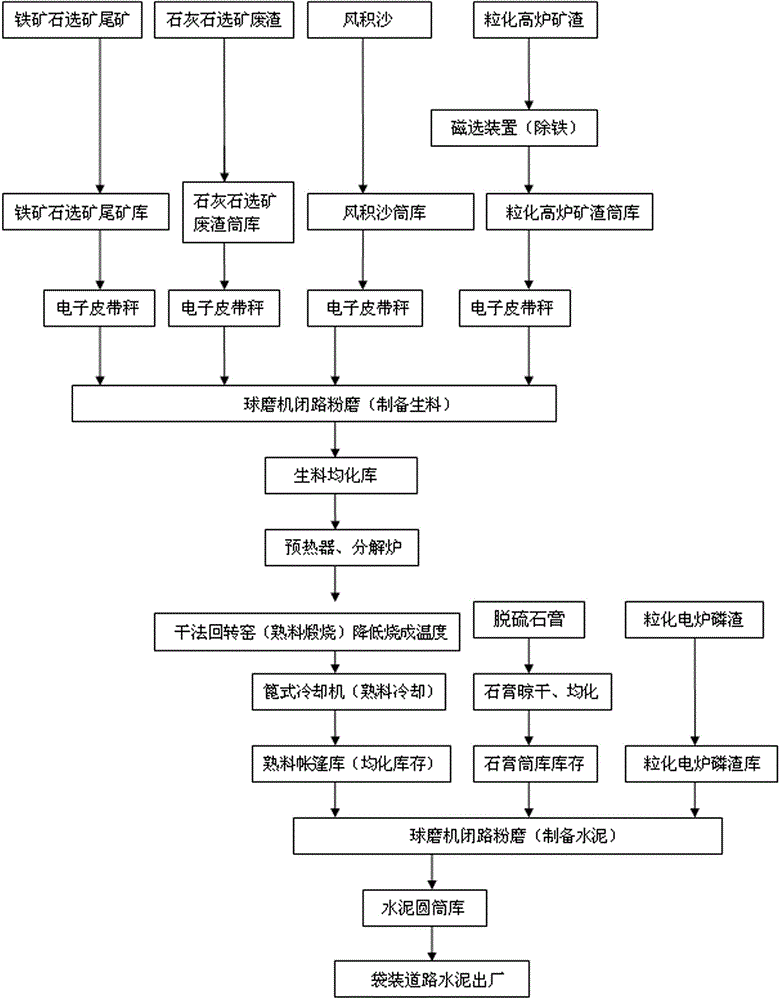

Method used

Image

Examples

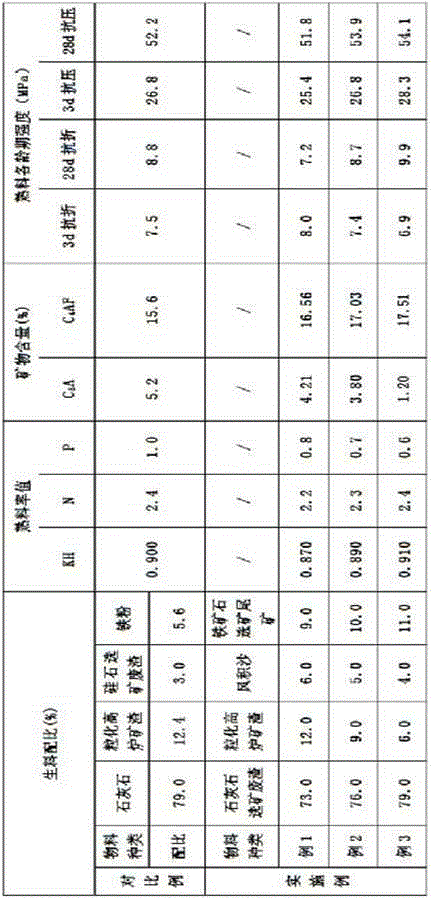

Embodiment 1

[0036] A. Raw meal ingredients: the following raw material ingredients in the following percentages by weight, iron ore beneficiation tailings 9%, limestone beneficiation waste slag 73%, aeolian sand 6%, granulated blast furnace slag 12%; ground into fine powder.

[0037] B. Clinker calcination

[0038] In the dry process cement rotary kiln, the raw meal powder is preheated, decomposed and calcined, and burned at a temperature of 1100°C until it is partially melted to obtain road Portland cement clinker;

[0039] C, cement batching, grinding

[0040] The road portland cement is prepared according to the conventional method with the following raw material ingredients in weight percentage, 88.0% of road portland cement clinker, 6.0% of desulfurized gypsum, and 6.0% of granulated electric furnace phosphorous slag.

Embodiment 2

[0042] A. Raw material ingredients: the following raw material ingredients in the following weight percentages, iron ore beneficiation tailings 10%, limestone beneficiation waste slag 76%, aeolian sand 5%, granulated blast furnace slag 9%; ground into fine powder.

[0043] B. Clinker calcination

[0044] In the dry-process cement rotary kiln, the raw meal powder is preheated and decomposed and calcined, and burned at a temperature of 1400°C until it is partially melted to obtain road Portland cement clinker;

[0045] C, cement batching, grinding

[0046] The road portland cement is prepared according to the conventional method with the following raw material ingredients in weight percentage, 88.0% of road portland cement clinker, 6.0% of desulfurized gypsum, and 6.0% of granulated electric furnace phosphorous slag.

Embodiment 3

[0048] A. Raw material ingredients: the following raw material ingredients by weight percentage, iron ore beneficiation tailings 11%, limestone beneficiation waste slag 79%, aeolian sand 4%, granulated blast furnace slag 6.0%; ground into fine powder.

[0049] B. Clinker calcination

[0050] In the dry-process cement rotary kiln, the raw meal powder is preheated and decomposed and calcined, and burned at a temperature of 1450°C until it is partially melted to obtain road Portland cement clinker;

[0051] C, cement batching, grinding

[0052] The road portland cement is prepared according to the conventional method with the following raw material ingredients in weight percentage, 88.0% of road portland cement clinker, 6.0% of desulfurized gypsum, and 6.0% of granulated electric furnace phosphorous slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com