Composite cement and preparation method thereof

A technology for compounding cement and cement clinker, applied in cement production, etc., can solve the problems of low activity, low added value, and easy volatility of heavy metals, and achieve the effects of inhibiting the dissolution of heavy metals, excellent physical properties, and promoting strength growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] One embodiment of the present invention proposes a kind of preparation method of composite cement, it comprises:

[0066] Mix 20 parts of lead-zinc slag and 10 parts of limestone and grind until the specific surface area is 550±50m 2 / kg, to get the mixed components;

[0067] Mix 65 parts of cement clinker and 5 parts of natural anhydrite, and grind until the specific surface area is 360±20m 2 / kg, to obtain the clinker component;

[0068] The mixing component and the clinker component are mixed in a weight ratio of 3:7 to obtain composite cement.

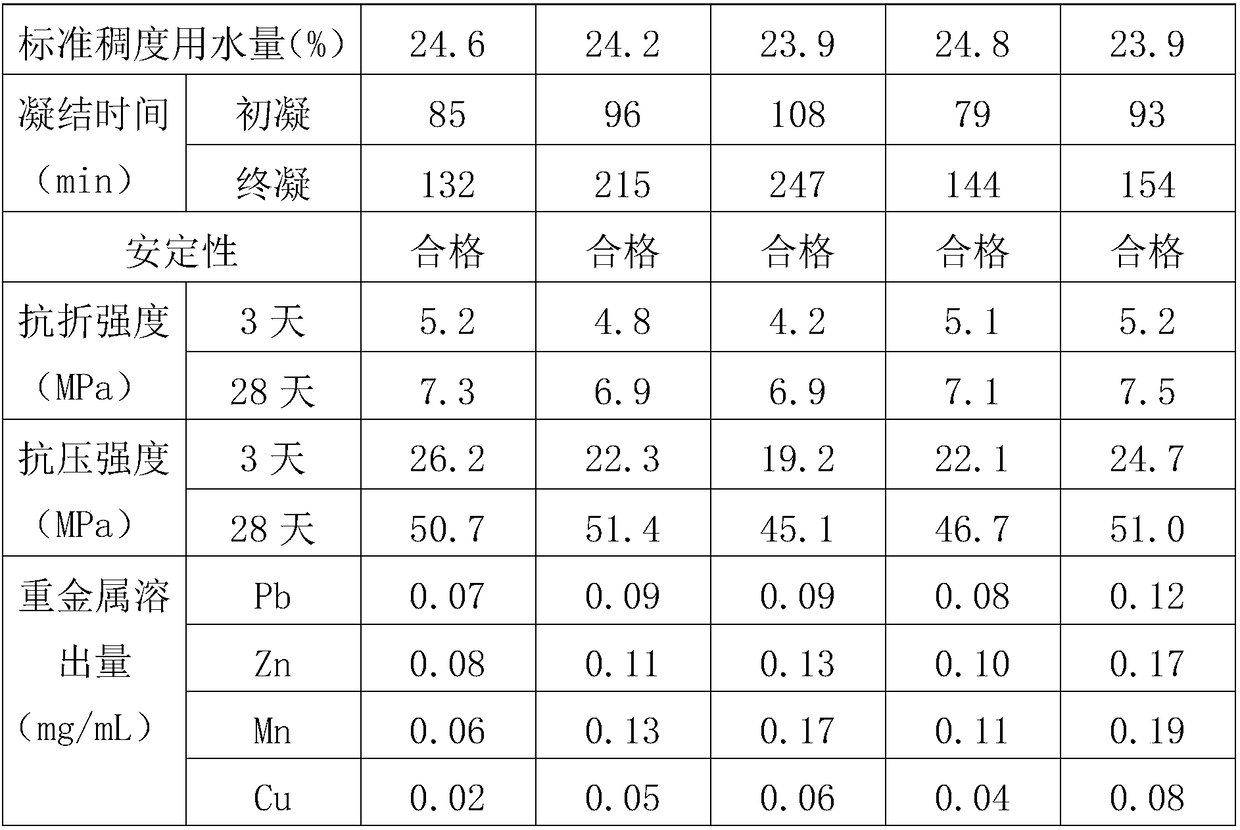

[0069] Another embodiment of the present invention provides a composite cement prepared by the method of Embodiment 1. The physical properties of the composite cement were tested according to GB / T17671 and GB / T 1346, and the heavy metal dissolution rate of the composite cement was tested according to GB / T 30810. The test results are shown in Table 1.

Embodiment 2

[0071] One embodiment of the present invention proposes a kind of preparation method of composite cement, it comprises:

[0072] Mix 20 parts of lead-zinc slag, 10 parts of slag, 15 parts of calcareous lead-zinc tailings, 51 parts of cement clinker and 4 parts of anhydrite, and grind them together until the specific surface area is 400±20m 2 / kg to obtain composite cement.

[0073] Another embodiment of the present invention provides a composite cement prepared by the method of Embodiment 2. The physical properties of the composite cement were tested according to GB / T17671 and GB / T 1346, and the heavy metal dissolution rate of the composite cement was tested according to GB / T 30810. The test results are shown in Table 1.

Embodiment 3

[0075] One embodiment of the present invention proposes a kind of preparation method of composite cement, it comprises:

[0076] Mix 20 parts of lead-zinc slag, 10 parts of fly ash, 12 parts of dolomite, 44 parts of cement clinker and 4 parts of phosphogypsum, and grind them together until the specific surface area is 420±20m 2 / kg to obtain composite cement.

[0077] Another embodiment of the present invention provides a composite cement prepared by the method of Embodiment 3. The physical properties of the composite cement were tested according to GB / T17671 and GB / T 1346, and the heavy metal dissolution rate of the composite cement was tested according to GB / T 30810. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com