Application of aeolian sand to preparation of synthetic paper

A technology of aeolian sand and synthetic paper, which is applied in the field of making materials and preparation of wallpaper, can solve the problems of ineffective filling, poor resin affinity, and high hardness of aeolian sand particles, saving processes and costs, and improving moisture permeability. performance, the effect of improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Amount of raw materials: 70% aeolian sand, 1% coupling agent, 3.5% lubricant, 0.5% stabilizer, 25% polyethylene.

[0022] Preparation of wallpaper: After dispersing and mixing the aeolian sand and coupling agent, put it into a grinder and grind it for about 1 hour, sort and sieve, take 600-800 mesh powder, add lubricant and stabilizer, mix it and put it into high-speed mixing After mixing by machine for 20 minutes, add polyethylene and stir and mix for 5 minutes, put it into the internal mixer for 20 minutes, extrude and pelletize, put the pellets into the flow calender to shape, and then emboss and print to make a web Wallpaper with a width of 1.2m.

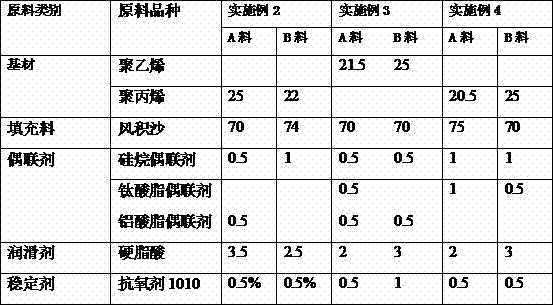

Embodiment 2—4

[0024] Create a wallpaper extruded from three layers. Among them, both the upper and lower layers use material A, and the middle layer uses material B. The raw material ratio of material A and material B is listed in the table below. The production method is to mix material A and material B with aeolian sand and coupling agent, grind, sieve, then mix with other raw materials, banbury, extrude and granulate, and then put them into a three-laminar flow calender Forming in the middle to make a three-layer structure wallpaper.

[0025] Embodiment 2-4 raw material consumption table (Kg)

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com